นวัตกรรมใหม่ล่าสุดของดอกสว่านจาก MOLDINO ที่จะทำให้งานเจาะเหล็กแข็ง ทำได้ง่ายและรวดเร็วยิ่งขึ้น เพียงการเจาะเพียงครั้งเดียวก็ได้ชิ้นงานที่มีความแม่นยำและเที่ยงตรงสูง เหมาะสำหรับกลุ่มอุตสาหกรรมแม่พิมพ์ที่ต้องการดอกสว่านที่สามารถเจาะผ่านวัสดุที่มีความแข็งสูงมากกว่า 55HRC

ดอกสว่านคาร์ไบด์แบบมีรูนํ้ามันรุ่นเอช เป็นดอกสว่านคาร์ไบด์รุ่นใหม่ที่ใช้สำหรับเจาะวัสดุที่มีค่าความแข็งสูง ด้วยรูปทรงของคมตัดที่ออกแบบให้มีทินนิ่ง s-x และร่องคายเศษด้านข้างแบบเกลียวตํ่า ซึ่งช่วยให้การคายเศษไหลรื่นดียิ่งขึ้น และเป็นตัวเลือกที่เหมาะสมเป็นอย่างยิ่งเมื่อต้องการเจาะรูที่มีความลึกสูง และอุปกรณ์เป่าลมเย็นไม่สามารถเข้าถึงได้

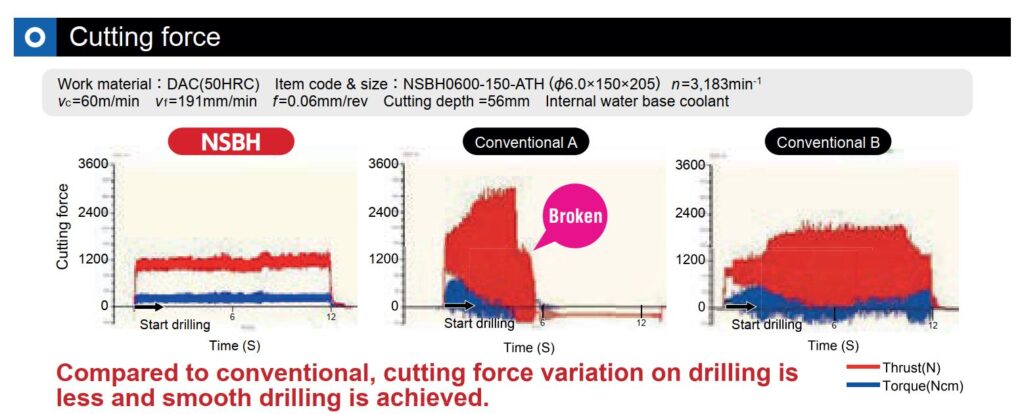

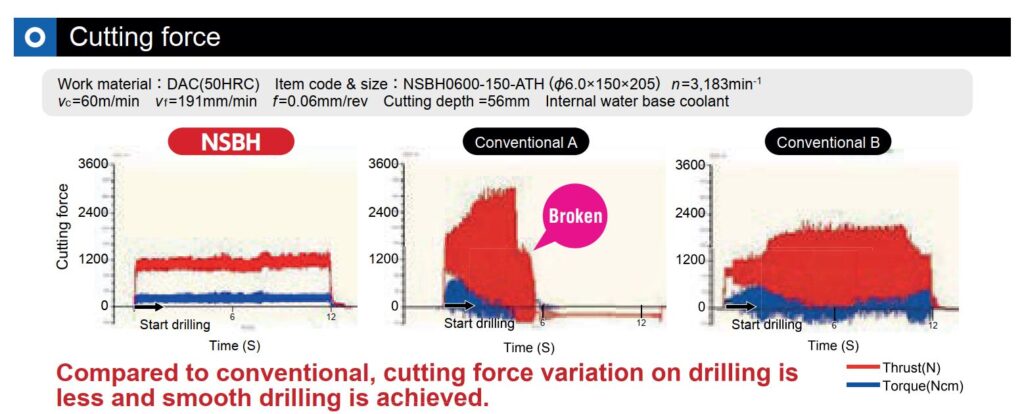

ซึ่งโดยทั่วไปในขณะที่ดอกสว่านคาร์ไบด์เจาะวัสดุที่มีค่าความแข็งสูงมากกว่า 55 HRC ความร้อนที่สะสมอาจทำให้คมตัดของดอกสว่านเสียหายได้ นอกจากนี้ เครื่องจักรยังต้องทำงานด้วยความเร็วในการตัดระดับตํ่าเพื่อลดการสะสมของความร้อน และเพื่อให้แน่ใจว่าคมตัดจะไม่เกิดความเสียหายหรือ แตก หัก ซึ่งความร้อนที่สะสมอยู่ อาจถูกระบายออกมาพร้อมกับเศษโลหะได้ เฉพาะเมื่อเศษโลหะไม่ติดหรือขดพันอยู่รอบหัวดอกสว่านเท่านั้น ดังนั้นการออกแบบรูปทรงหัวดอกสว่านและร่องคายเศษให้สามารถระบายเศษการด้านล่างให้ออกไปได้ดี จึงมีบทบาทสำคัญในการลดการสะท้านขณะเจาะชิ้นงาน ช่วยยืดอายุการใช้งานของเครื่องมือรวมถึงช่วยเพิ่มประสิทธิภาพในการทำงานได้อีกด้วย

รูปทรงที่ได้รับการพัฒนาขึ้นใหม่สำหรับดอกสว่าน NSBH มาพร้อมสารเคลือบผิว ATH ที่มีคุณสมบัติในการปกป้องสารตั้งต้นคาร์ไบด์และปกป้องคมตัดประสิทธิภาพสูง โดยสารเคลือบ ATH เป็นเทคโนโลยีการเคลือบผิวที่ถูกพัฒนาขึ้นอีกขั้นของ MOLDINO ที่ช่วยป้องกันการเกิดออกซิเดชั่นได้ดียิ่งขึ้น ช่วยทำให้อายุการใช้งานเครื่องมือยาวนานขึ้น และเพิ่มประสิทธิภาพในการตัดวัสดุที่มีความแข็งสูงได้มากถึง 70 HRC

NSBH-ATH รับประกันประสิทธิภาพที่เหนือกว่าเมื่อเจาะวัตถุแข็ง

คุณสมบัติเด่นของดอกสว่าน NSBH-ATH

• ความทนและแรงคมตัดสูงสำหรับเหล็กที่มีความแข็งสูง

• การกำจัดเศษโลหะทำได้ง่ายด้วยรูปทรงร่องแบบพิเศษ

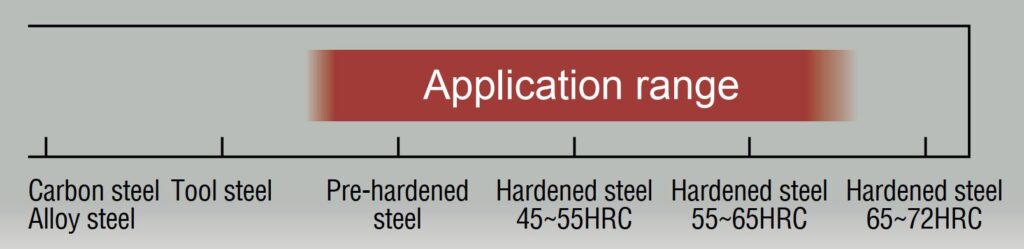

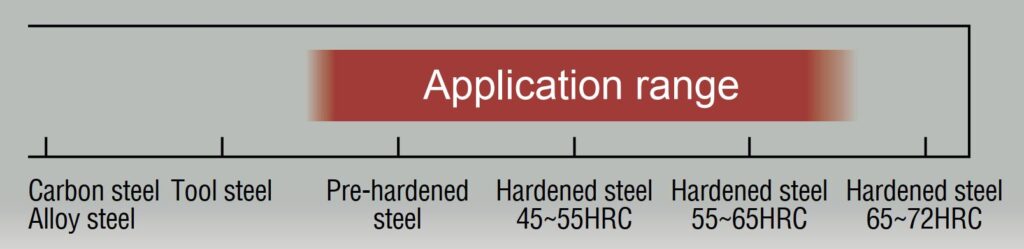

ขอบเขตการใช้งาน

• Carbon steel / Alloy steel

• Tool steel

• Pre-hardened steel

• Harden steel 45-55 HRC

• Harden steel 55-65 HRC

• Harden steel 65-72 HRC

จุดเด่นของสารเคลือบ ATH

• ความแข็งและการป้องกันการเกิดออกซิเดชั่นที่มีสารเคลือบ TH เพิ่มขึ้น ทำให้อายุการใช้งานของดอกสว่านยาวนานและมีประสิทธิภาพมากขึ้นเมื่อดอกสว่านตัดวัตถุความแข็งสูง (สารเคลือบนาโนคอมโพสิตชนิดซิลิคอนด้วยอนุภาคคริสตัลที่ละเอียดขึ้น)

• ดอกสว่านมีประสิทธิภาพยอดเยี่ยมเมื่อตัดวัตถุที่มีความแข็งสูง (55HRC หรือสูงกว่า) เหล็กแม่พิมพ์งานเย็น HSS เหล็กกล้าเครื่องมือ

• ดอกสว่านมีอายุการใช้งานยาวนานสำหรับทั้งการตัดแบบแห้งและการตัดแบบเปียก

Article by: J.SRI RUNG RUENG IMPEX CO.,LTD

https://www.jsr.co.th/ Click Here