Tool holder performance significantly impacts cutting performance by affecting precision, stability, tool life, and surface finish. A well-designed tool holder ensures a rigid and accurate connection between the cutting tool and the machine’s spindle, minimizing vibration and maximizing cutting efficiency. This leads to more precise cuts, longer tool life, and better surface quality.

MEGA Tech explores the new Hydraulic Chuck from Big Daishowa. However, getting the right tools is only half-way, you need good practice to complete the goal. So, we walk through smart tool holder tips from an expert from Big Daishowa as well.

You Need the Right Tools for Applications

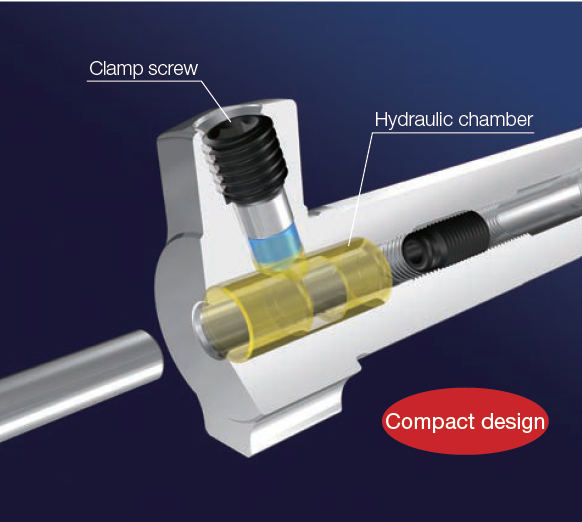

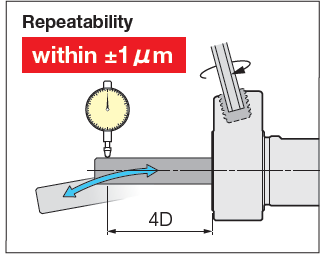

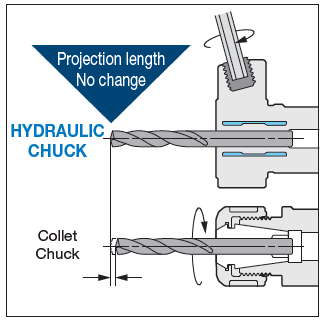

First, we need the right tool for a particular job. Different clamping methods offer varying advantages depending on the application. For turning operations, Big Daishowa recommends the Hydraulic Chuck for high-precision drilling and reaming on CNC automatic lathes. The design allows for easy tool-changing even inside a machine with limited space. High precision repeatability of less than 1μm at 4d helps drastically improve the tool life. The cutting tool can be clamped or unclamped easily and securely with just one wrench. Since the projection length of the cutting tool does not change before and after tightening the clamp screw, it is easy to adjust the length on the machine.

Integrated design gains stable precision and high rigidity compared to the two-piece structure sealed with O-rings offering high durability and easy maintenance. Further, the runout accuracy is greatly improved by the short projection length and the dual oil pressure points. There are three types of Hydraulic Chuck: Front-side Clamping Type, Back-side Clamping Type, and Rear-post type.

10 Tips for Optimal Tool Clamping Performance

As mentioned earlier, the integrity of tool clamping, especially for the turned part machining, can make or break the jobs. Here, we get 10 tool holder tips from Big Daishowa’s expert sharing some of their best advice for maximum tool holder performance in different situations:

- Balance holders as a complete assembly. Always balance tool holders as a complete assembly. While many tooling providers pre-balance their holders at the factory, it’s often inadequate, especially for long-reach applications.

- Holder damage can go from bad to worse quickly. Inspect and care for your holders. Trauma on a holder or spindle—dings, scratches, gouges, etc.—can magnify quickly. One bad holder can spread its problems like an illness. If you’re seeing disruptions like these on your holders, get them out of the rotation.

- The rule of thumb on holder dimensions. Looking for affordable ways to avoid vibration? Start by opting for a holder with a combination of the largest diameter and shortest length possible.

- Rigidity can harm tapping operations. The perceived rigidity of collet chucks can be detrimental. Rigidity does very little to counteract the dramatic thrust loads imposed on the tap and part, exacerbating the already difficult challenge of weathering the stop/reverse and maintaining synchronization.

- Balancing is crucial to five-axis machining. Bear in mind that balance may be of most importance in full five-axis work. A well-balanced holder helps ensure the cutting edge of the end mill must be consistently engaged with the material in order to prevent chatter and poor surface finish quality.

- Consider spindle speed requirements when choosing between shrink-fit and hydraulic holders. In a long-reach application, consider the spindle speed required. For a hydraulic used within its recommended operating range, a hydraulic tool holder offers superior runout and repeatability.

- Don’t overlook the tool’s effect on holder performance. The cutting tool affects holding ability more than most machinists and engineers realize.

- Not all dual-contact tooling is the same. Only a licensed supplier of BIG-PLUS has master gages that are traceable to the BIG grand master gages and have the dimensions and tolerances provided to make holders right. Look for the marking: “BIG-PLUS Spindle System-License BIG DAISHOWA SEIKI.”

- You may have a BIG-PLUS spindle and not even know it. The easiest way to know if an interface is BIG-PLUS is to place a standard tool into the spindle and see how much of a gap there is between the tool holder’s flange face and spindle face. If it is BIG-PLUS, the gap should be about 0.06 inches.

- Use positive offsets during holder setup. Adapting machines to a single presetter so they can receive positive gauge lengths is superior to using all types of machine-specific negative offsets. It’s a relatively small and simple step that makes life much easier.

Article by: MEGATech & Sumipol Corporation Limited << Click here