YG Mill High Feed 4 เป็นเม็ดมีด High Feed รุ่นใหม่ พัฒนาขึ้นมาเพื่อตอบโจทย์การใช้งานหลากหลาย เพื่อเพิ่มผลผลิต และทำงานอย่างเสถียร ในอุตสาหกรรมปัจจุบัน เครื่องมือดังกล่าว มักใช้ในงานแม่พิมพ์ทั้ง Mold และ Die ใช้ในงานผลิตชิ้นส่วนที่ใช้ผลิตกระแสไฟฟ้า และประยุกต์อย่างหลากหลายในงานวัสดุสำหรับตลาดขึ้นรูปวัสดุทั่วไป โดยแนวคิดของ YG Mill HF4 จะโดดเด่นกว่าเพราะเป็นตัวเลือกเครื่องมือที่เหมาะสมกับการกัดงานขนาดเล็กที่ต้องการ High Feed

ความหนาที่เป็นเอกลักษณ์ของYG-1 ENMX ทำให้รุ่นนี้มีข้อดีหลายอย่าง โดยปกติแล้ว ความสึกหรอที่พบเห็นในงานกัดไฮฟีดก็คือ ความสึกหรอด้านข้าง (Flank Wear) และเมื่อความสึกหรอขยายออกไป มันก็จะไปกระทบกับขอบที่สอง เนื่องจากเราทำให้เม็ดมีด (Insert) หนาขึ้น 20-25% เมื่อเทียบกับรุ่นอื่นในตลาด จึงทำให้ความสึกหรอดังกล่าวไม่ไปกระทบกับขอบที่สอง จึงสามารถใช้งานทั้ง 4 ขอบได้อย่างเต็มที่ และเป็นเครื่องมือที่คุ้มค่าเงิน ความหนาของเม็ดมีดทำให้การยึดจับมั่นคง และทำให้การใช้งานเครื่องเสถียรเป็นไปตามที่วางแผน และช่วยยึดอายุของเครื่องมือเมื่อต้องใช้งานหนัก

เม็ดมีดเนกาทีฟ (Negative Insert) ที่หนากว่าเดิม ทำให้มีมุมคายเป็นบวก (Positive Rake Angle) ซึ่งช่วยกำจัดเศษวัสดุ และลดภาระงานของเครื่องจักร (machining load) การออกแบบที่ช่วยปกป้องมุม ทำให้เครื่องจักรอยู่นิ่ง และช่วยเพิ่มอายุของเครื่องมือ พร้อมกับ Chip-Breaker ที่ใช้งานอย่างมีประสิทธิภาพ

ENMX Cylindrical Cutter มีเส้นผ่าศูนย์กลางตั้งแต่ 16 มม ถึง 33 มม (0.75”-1.25”) และ ENMX Shell Mills มีขนาดตั้งแต่ 40 มม ถึง 50 มม (1.5”-2”)

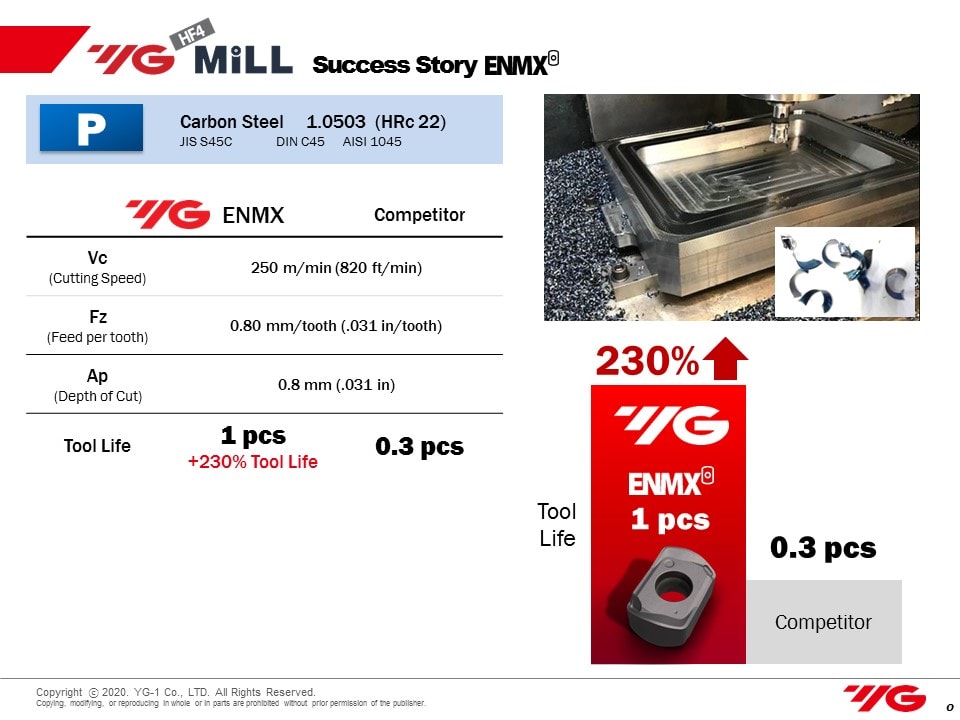

จากภาพที่ 1 ENMX สามารถแสดงให้เห็นว่าการทำงานเสถียร แรงตัดต่ำ (Cutting Force) และอายุเครื่องมือดีขึ้นกว่าประมาณ 230 เปอร์เซ็นต์ เมื่อเทียบกับเครื่องมือที่ใช้เปรียบเทียบในการทำงานกับ Carbon Steel C45 ซึ่งมักจะทำให้เม็ดมีดบิ่นและทำให้เครื่องมือแตกหัก เม็ดมีด YG Mill HF4 เป็นเครื่องมือที่ตอบโจทย์การทำงานไฮฟีดที่หนักหน่วงของคุณ และคุ้มค่าอย่างที่ไม่มีรายไหนเทียบได้แน่นอน คุณสามารถเพิ่มผลผลิตของคุณด้วยเม็ดมีด YG Mill HF4 ตั้งแต่วันนี้ได้เลย

Article by: YG-1 (Thailand) Co., Ltd. & MEGA Tech Magazine