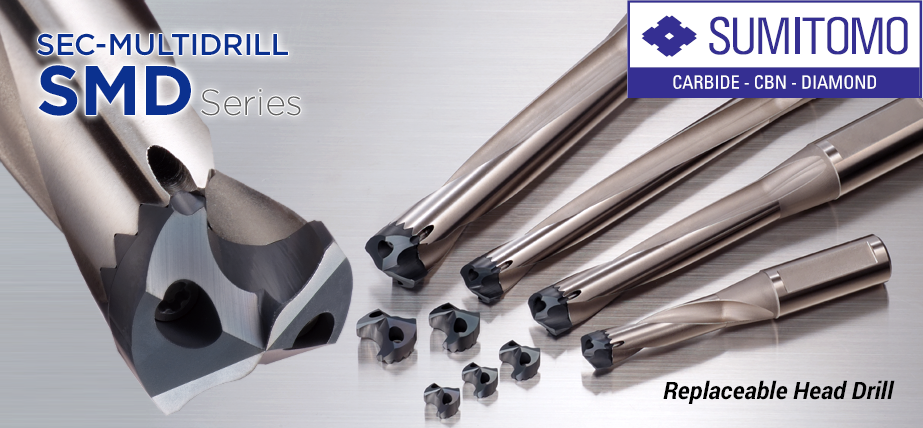

ในคอลัมน์ Cutting Tools Tips ฉบับนี้ ทาง MEGA Tech ยินดีนำเสนอเรื่องราวความเป็นมา ของดอกสว่าน ของ Sumitomo ก่อนที่จะเป็น ดอกสว่าน รุ่น SMD ในรุ่นปัจจุบัน ที่ให้ความเรียบของผิวได้ดียิ่งขึ้นกว่าเดิม

ในประวัติศาสตร์กว่า 80 ปีของซีเมนต์คาร์ไบด์ การพัฒนาและการเปิดตัว ดอกสว่านซีเมนต์คาร์ไบด์ เป็นเหตุการณ์ที่มีความสำคัญอย่างมาก ซึ่งทำให้การตัดเฉือนโลหะในอุตสาหกรรมการผลิตมีวิวัฒนาการอย่างก้าวกระโดด ในด้านงานเจาะนั้นเชื่อกันว่าเป็นการยากสำหรับการใช้ซีเมนต์คาร์ไบด์ด้วยเหตุผลด้านความแข็งแรง ในปี พ.ศ. 2525 โยชิคัตสึ โมริ วิศวกรของซูมิโตโม อิเล็กตริก ฮาร์ดเมทัล คอร์ป. ได้เผชิญหน้ากับความท้าทายนี้อย่างกล้าหาญ

ดอกสว่านแตกต่างจากเครื่องมือตัดอื่น ๆ เนื่องจากขณะที่ทำการเจาะก็ต้องทำหน้าที่คายเศษที่เกิดขึ้นระหว่างการตัดจากด้านล่างของรูเพิ่มขึ้นมาด้วย ซึ่งมีผลทำให้การพัฒนาดอกสว่านคาร์ไบด์ทำได้ค่อนข้างยาก ข้อกำหนดสำคัญประการหนึ่งสำหรับการเจาะในการขึ้นรูปโลหะคือ ดอกสว่านต้องไม่หัก หากไม่มีการคายเศษ ดอกสว่านก็จะหัก หากต้องการให้เศษคายออกมาอย่างราบรื่น ร่องฟันก็ต้องกว้าง หากมีร่องฟันกว้าง ก็จะส่งผลให้พื้นที่หน้าตัดลดลงตามไปด้วย และดอกสว่านก็จะมีความแข็งแรงลดลง โดยสรุปแล้ว ประเด็นสำคัญคือการขยายหน้าตัดของดอกสว่านเพื่อเพิ่มความแข็งแรงและคายเศษอย่างราบรื่นผ่านร่องฟันที่แคบ ซึ่งถือเป็นความท้าทายที่ยากที่สุด

“สิ่งที่เราควรจะทราบก็คือ เศษขนาดใหญ่จะติดอยู่ในร่องฟันของดอกสว่าน อย่างไรก็ตามเศษที่สั้นและบางจะถูกคายออกอย่างราบรื่น ด้วยกระบวนการพัฒนาและประเมินผลจากงานต้นแบบซ้ำแล้วซ้ำเล่า เราค้นพบว่า การใช้คมตัดที่มีรูปทรงโค้งมน สามารถสร้างเศษที่สั้นและบางเพื่อการคายเศษที่ราบรื่นได้ ซึ่งถือเป็นความก้าวหน้าครั้งสำคัญที่สุดในการพัฒนาดอกสว่านคาร์ไบด์” โมริ เล่าให้ฟัง

ในปี พ.ศ. 2527 หลังจากช่วงการพัฒนาสองปี การผลิตและการขายดอกสว่านมัลติดริลล์ (Multidrill) เริ่มขึ้น โดยตลาดต้อนรับสินค้านี้เป็นอย่างดี ดอกสว่านมัลติดริลล์ได้รับเลือกอย่างต่อเนื่องโดยลูกค้าจำนวนหนึ่ง ซึ่งรวมถึงผู้ผลิตรถยนต์รายใหญ่ และมีความต้องการเพิ่มขึ้นอย่างรวดเร็ว เมื่อเปรียบเทียบกับดอกสว่านเหล็กกล้าความเร็วสูงทั่วไปแล้ว ดอกสว่านมัลติดริลล์มีประสิทธิภาพการตัดเฉือนเพิ่มขึ้น 4 ถึง 6 เท่า ทำให้ประสิทธิภาพการผลิตในการตัดเฉือนเพิ่มขึ้นอย่างเห็นได้ชัดเจน

อย่างไรก็ตาม ดอกสว่านเป็นเครื่องมือตัดที่ไม่อาจจะแสดงประสิทธิภาพที่แท้จริงออกมาได้ ทั้งนี้ขึ้นอยู่กับเครื่องจักรที่ใช้ การตั้งค่าเงื่อนไขการทำงาน และการใช้งาน เพื่อแก้ปัญหานี้ พวกเขาได้ส่งเสริมกิจกรรมการเรียนรู้เพิ่มขึ้น เช่น การเยี่ยมเยียนผู้ใช้ การพัฒนา และการจัดหากรอบการฝึกอบรม และการสัมมนาฝึกอบรม ความพยายามเหล่านี้กระตุ้นให้มีการใช้ดอกสว่านมัลติดริลล์อย่างกว้างขวางมากขึ้น

ระหว่างการใช้งาน คมตัดของดอกสว่านจะสึกและไม่มีประสิทธิภาพในการตัด หากต้องการใช้ดอกสว่านอีกครั้ง จำเป็นต้องลับคมตัดอีกครั้งเพื่อให้กลับคืนสภาพเดิม โดยธรรมชาติแล้ว คุณภาพของคมตัดที่ลับให้คมอีกครั้งจะต้องดีเท่ากับของดอกสว่านใหม่เอี่ยม ในขณะเดียวกัน ลูกค้าก็ต้องการรับบริการด้วยต้นทุนที่ต่ำและภายในกำหนดการส่งมอบที่รวดเร็ว เพื่อรับมือกับความท้าทายเหล่านี้ พวกเขาได้สร้างโมเดลใหม่สำหรับงานลับคมใหม่ โดยร่วมมือกับบริษัทผู้ให้บริการด้านงานเจียรทั่วประเทศญี่ปุ่น นอกจากนี้ พวกเขายังทำงานเกี่ยวกับการพัฒนาอุปกรณ์ลับคมใหม่ และจัดหาโปรแกรมให้กับผู้ผลิตเครื่องจักร

นับตั้งแต่เปิดตัวสู่ตลาดในญี่ปุ่นและต่างประเทศเป็นเวลาประมาณ 35 ปี ดอกสว่านมัลติดริลล์ได้พัฒนาไปในหลากหลายรูปแบบและมีบทบาทสำคัญในการสร้างสรรค์นวัตกรรมใหม่ให้กับสถานประกอบการในแง่ของการปรับปรุงประสิทธิภาพการผลิตและการลดต้นทุน

ซูมิโตโม อิเล็กตริก กรุ๊ป กำลังใช้แนวทางต่าง ๆ ในการสร้างวัสดุใหม่ในด้านวัสดุโลหะและวัสดุอนินทรีย์ และนวัตกรรมด้านกระบวนการซึ่งใช้เทคโนโลยีแรงดันสูงและผงโลหะพิเศษที่เป็นกรรมสิทธิ์ของบริษัท ไม่ต้องสงสัยเลยว่าดอกสว่านมัลติดริลล์ของ ซูมิโตโม อิเล็กตริก จะยังคงพัฒนาต่อไปในอนาคต เพื่อช่วยสร้างสรรค์สถานประกอบการผลิตในทุกส่วนของโลก และมีบทบาทในการปูทางสำหรับการผลิตยุคใหม่

Article by: Sumipol Corporation Limited & MEGA Tech