ระบบการจับยึดเครื่องมือได้มีการพัฒนาอย่างต่อเนื่อง เพื่อตอบโจทย์ด้านคุณภาพของผิวชิ้นงาน ความแม่นยำ ความเที่ยงตรง พร้อมทั้ง คุณภาพของเครื่องจักรและทูลที่นำมาใช้งาน ให้สอดคล้องและเหมาะสมกับการใช้งานในรูปแบบต่างๆ เพื่อให้เกิดประโยชน์สูงสุด

Big-Plus® Spindle System ซึ่งเป็นลิขสิทธิ์เฉพาะของ BIG DAISHOWA CO., LTD. นับเป็นเทคโนโลยีระบบการจับยึดที่น่าจับตามองเป็นอย่ายิ่ง เนื่องจากเป็นระบบที่สนับสนุนไปสู่การสร้างประสิทธิภาพสูงสุดในการผลิต ซึ่งได้รับการการันตีมาตรฐานและคุณภาพด้วยรางวัลผลงานประดิษฐ์คิดค้นดีเด่น IKemoto Award ในงานมอบรางวัลผลงานประดิษฐ์คิดค้นครั้งที่ 23

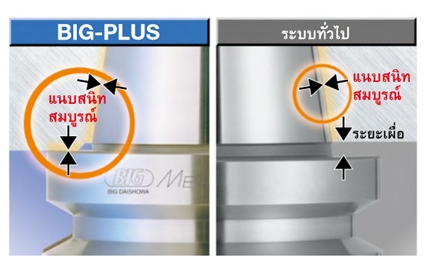

Big-Plus® Spindle System: ระบบหน้าสัมผัสสองด้าน

Big-Plus® Spindle System นั้น มีคุณสมบัติพิเศษและแตกต่างด้วยการที่ระบบนี้จะสร้างหน้าสัมผัสสองด้านระหว่างหน้าสัมผัสของเทเปอร์และหน้าแปลนโดยอิงมาตรฐานจากระบบเกจ โดยมีผู้ผลิตที่นำไปใช้งานในประเทศญี่ปุ่น 67 บริษัทด้วยกัน และอีก 96 บริษัทในต่างประเทศ

โดยประโยชน์ที่ได้รับจากการใช้ BIG-PLUS ประกอบด้วย

- ปรังปรุงผิวงานกัดและความแม่นยำของมิติ

- ยืดอายุการใช้งานของเครื่องมือ

- ป้องกันการกัดกร่อนแบบถูครูดที่มีสาเหตุมาจากการสั่นสะท้านเมื่อใช้งานแบบกัดหนัก

- ปรับปรุงความแม่นยำในการเปลี่ยนทูลแบบ ATC

- เพิ่มความเสถียรของแนวแกน Z เมื่อใช้งานด้วยความเร็วรอบสูง

- ปรับปรุงความกลมในการคว้าน

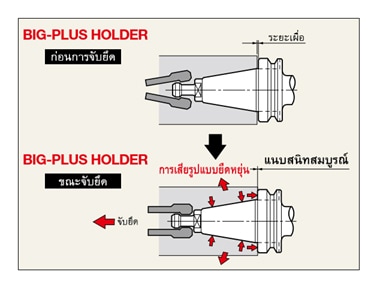

ระยะดึงเข้าของหัวจับเป็นกุญแจสำคัญ

เพื่อทำให้หน้าสัมผัสแนบสนิทสมบูรณ์

ก่อนที่จะจับยึดกับหัวจับยึดเครื่องมือ จะมีระยะเผื่อเล็กน้อยที่หน้าสัมผัสของหน้าแปลน แรงดึงจากอุปกรณ์ที่ใช้ดึงจะส่งผลให้เทเปอร์ของสปินเดิลเกิดการยืดขยายตัวกว้างขึ้น ทำให้หน้าสัมผัสแนบสนิทสมบูรณ์ เพราะฉะนั้นระยะดึงเข้าจึงสำคัญต่อการแบบสนิทอย่างสมบูรณ์

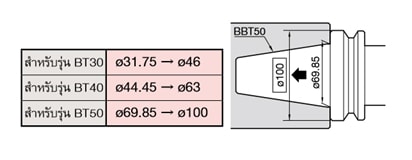

ขนาดเส้นผ่านศูนย์กลางของหน้าสัมผัสที่เพิ่มขึ้น

ทำให้ความแข็งเกร็งสูงขึ้น

หัวจับยึดเครื่องมือ BT แบบทั่วไปจะนั่งอยู่บนขนาดเส้นผ่านศูนย์กลางอ้างอิงที่เรียกว่าหน้าสัมผัสเกจ แต่ในทางกลับกัน หัวจับเครื่องมือ BIG-PLUS จะนั่งอยู่บนหน้าแปลน ซึ่งช่วยปรับปรุงความแข็งเกร็งให้สูงขึ้นอย่างชัดเจน

การควบคุมการวัดอย่างเข้มงวดผ่านระบบเกจวัดที่กำหนดไว้

สปินเดิล BIG-PLUS ได้รับการผลิตขึ้นโดยผู้ผลิตเครื่องจักรหรือผู้ผลิตสปินเดิลที่ได้รับอนุญาตภายใต้การควบคุมมิติอย่างเข้มงวดด้วย BIG MASTER GAUGE ต้นแบบเฉพาะหัวจับที่มีเครื่องหมายการค้า BIG-PLUS เท่านั้น ที่สามารถใช้งานสปินเดิลเหล่านี้ได้อย่างเต็มประสิทธิภาพและปลอดภัย

MEGA CHUCK SERIES PAT. เป็นหัวจับยึดเครื่องมือความเร็วสูงซึ่งใช้เทคโนโลยีหน้าสัมผัสสองด้าน BIG-PLUS เพื่อรองรับการผลิตที่ต้องการชิ้นงานประสิทธิภาพสูง โดย MEGA CHUCK SERIES PAT. มีการออกแบบที่ให้ความสมดุลสูง ผิวรอบนอกได้รับการเจียรอย่างละเอียด อีกทั้ง มีการตรวจสอบความสมดุลด้วยไดนามิกบาลานเซอร์ซึ่งมีความเที่ยงตรงสูง

โดยรุ่น MEGA เหมาะสำหรับการหมุนด้วยความเร็วสูง ขันล็อกแน่นสนิทด้วยประแจ MEGA นัทรุ่น MEGA ดีไซน์แบบ Notch-free (PAT.) จึงป้องกันการสั่นสะเทือนและลดเสียงรบกวน อีกทั้ง คุณสมบัติอันโดดเด่นของประแจ MEGA ช่วยให้การขันนัทเป็นงานที่ง่ายขึ้น เนื่องด้วยประแจ MEGA ใช้ระบบคลัทช์ทางเดียว จึงสามารถให้แรงได้อย่างสม่ำเสมอที่เส้นรอบวงของนัททั้งหมด เพื่อการขันแน่นสนิทอย่างปลอดภัย นอกจากนี้ ลักษณะการทำงานแบบหมุนทางเดียว ยังทำให้การขัน

ล็อกนัททำได้คล่องตัวและเบาสบายมากขึ้น

การเลือกใช้เทคโนโลยีขั้นสูงเป็นกลยุทธ์ที่สำคัญ เพื่อนำไปสู่การสร้างความได้เปรียบในภาวะการแข่งขันที่นับวันจะรุนแรงมากขึ้น โดย Big-Plus® Spindle System เป็นเทคโนโลยีที่จะสนับสนุนให้การทำงานของอุปกรณ์จับยึดเปี่ยมด้วยประสิทธิภาพและสอดคล้องไปกับเทรนด์การผลิตในปัจจุบัน

MEGA CHUCK SERIES PAT. เลือกใช้เทคโนโลยี BIG-PLUS

Article by: BIG DAISHOWA SEIKI CO., LTD. & MEGA Tech