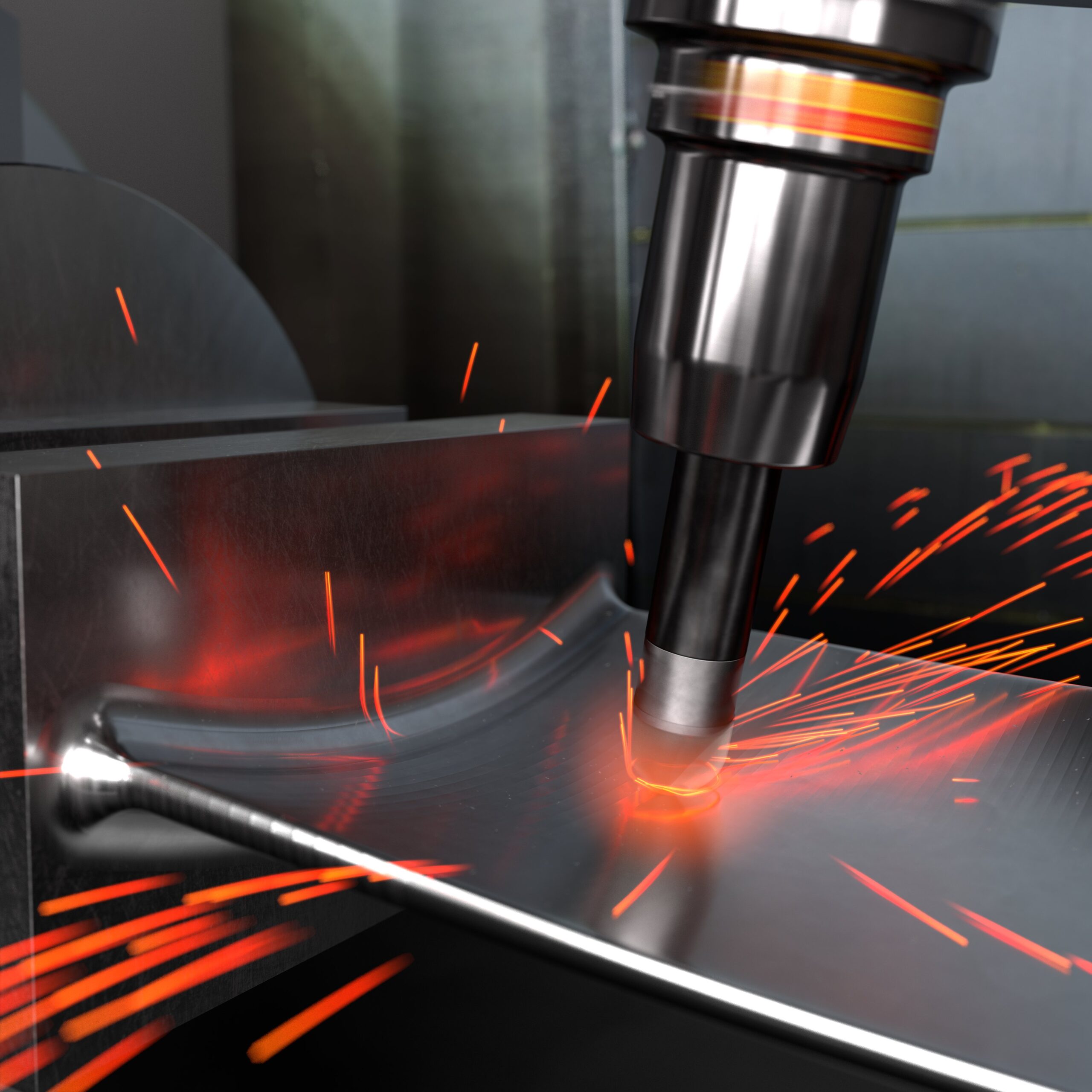

ในปัจจุบัน เครื่องแมชชีนนิ่งเซ็นเตอร์และเครื่องจักรมัลติทาสก์ได้กลายมาเป็นส่วนสำคัญที่ขาดไม่ได้ของงานตัดเฉือนโลหะ ซึ่งส่งผลให้เครื่องมืออย่างดอกเอ็นมิลโซลิดคาร์ไบด์ได้รับประโยชน์ตามไปด้วยเช่นกัน ความง่ายในการใช้งานและประสิทธิภาพของดอกเอ็นมิลสามารถตอบโจทย์ความต้องการได้ ทั้งในแง่ของการลดความซับซ้อนของการปรับตั้งเครื่องมือและการทำงานให้ได้หลายขั้นตอนมากที่สุดด้วยเครื่องจักรอเนกประสงค์เครื่องเดียว

MEGA Tech ขอแนะนำผลิตภัณฑ์จาก Sandvik Coromant ซึ่งในวันนี้ เราจะมาดูกันว่า ความเชี่ยวชาญด้านงานตัดเฉือนโลหะของ Sandvik Coromant สามารถปูทางสู่นวัตกรรมใหม่ของงานกัดได้อย่างไร

ดอกเอ็นมิลโซลิดคาร์ไบด์ทั่วไปจะมีขนาดเส้นผ่านศูนย์กลางตั้งแต่ 2 ถึง 16 มิลลิเมตร (0.079 ถึง 0.625 นิ้ว) แต่ดอกเอ็นมิลในกลุ่มเส้นผ่านศูนย์กลางขนาดใหญ่จะเริ่มมีลักษณะการใช้งานใกล้เคียงกับกลุ่มดอกกัดแบบถอดเปลี่ยนหัวได้และหัวกัดแบบเม็ดมีด ซึ่งเครื่องมือสองประเภทหลังนี้ ยิ่งมีเส้นผ่านศูนย์กลางใหญ่ขึ้น ก็จะยิ่งมีความคุ้มค่ามากกว่า

Sandvik Coromant มุ่งมั่นเป็นพิเศษที่จะออกแบบเครื่องมือกัดโซลิดคาร์ไบด์ที่เชื่อถือได้มากขึ้นและมีประสิทธิภาพมากขึ้น โดยเน้นไปที่ชิ้นงานในกลุ่มวัสดุเหล็กกล้า (ISO P) และเหล็กสเตนเลส (ISO M) จนกระทั่งได้ออกมาเป็นเครื่องมือในตระกูล CoroMill Plura HD ซึ่งมีให้เลือกทั้งหมดหกแบบ รวมทั้งออกแบบมาโดยเฉพาะสำหรับงานกัดหยาบหนักที่ต้องการประสิทธิภาพสูงสุดในการตัดเฉือนเนื้อวัสดุจำนวนมาก

เครื่องมือรุ่นนี้ผ่านการออกแบบด้วยวิธีไฟไนต์อิลิเมนต์ ( FEM ) ให้ร่องคายเศษให้มีปริมาตรสูง ทำให้ได้ประสิทธิภาพการคายเศษสูงสุดและสามารถใช้ได้กับงานกัดร่องแบบเต็มหน้า รวมทั้งมีคมตัดที่ปลายดอกที่ผ่านการออกแบบมาโดยเฉพาะ ทำให้สามารถใช้ได้กับการกัดไล่ระดับที่มีความชันสูง

นอกจากนี้ ดอกเอ็นมิล CoroMill Plura HD ยังสามารถใช้งานได้ง่ายและให้ความเชื่อถือได้สูง เนื่องจากรองรับช่วงค่าการตัดได้กว้าง โดยเป็นผลมาจากระยะพิทช์แบบไม่เท่ากันที่ช่วยลดการสั่นสะท้าน และทำให้สามารถใช้ความเร็วตัดได้สูงสำหรับงานกัดบ่าที่ใช้หน้าสัมผัสมีดกว้าง

ร่องคายเศษนวัตกรรมใหม่ของเครื่องมือในตระกูล ดอกเอ็นมิล CoroMill Plura ให้ประสิทธิภาพสูงเป็นพิเศษสำหรับงานกัดบ่าที่ใช้หน้าสัมผัสมีดกว้าง รวมไปถึงการกัดร่องแบบเต็มหน้าที่ใช้ระยะกินลึกมาก (สูงสุด 2 x DC)

กรณีศึกษา: อายุการใช้งานนานกว่าถึง 253%

ความท้าทาย: การเพิ่มประสิทธิภาพให้กับงานกัดด้วยดอกเอ็นมิล พร้อมทั้งเพิ่มความเชื่อถือได้ให้กับกระบวนการทำงาน

คำตอบ: เลือกใช้ระบบเครื่องมือที่ออกแบบมาโดยเฉพาะ ตั้งแต่ตัวจับยึดดอกเอ็นมิลไปจนถึงรูปทรงคมตัดและเกรดคาร์ไบด์

ลูกค้ารายหนึ่งในธุรกิจผลิตอุปกรณ์ทางการแพทย์ได้ทำการทดสอบ CoroMill Plura HD ในแง่ของความเชื่อถือได้และอายุการใช้งานโดยใช้ค่าการตัดเท่าเดิม ผู้ผลิตรายนี้ทำการทดสอบเครื่องมือกับชิ้นงานสามแบบ โดยชิ้นงานแรกเป็นวัสดุเหล็กกล้า P1.4.Z.AN – AISI/SAEm ชิ้นที่สองเป็นเหล็กกล้าหล่อ ASTM A732 2Q และชิ้นที่สามเป็นเหล็กกล้าหล่อ ASTM A27 เกรด N2 โดยหลังจากการทดลองตัดเฉือนโดยใช้ค่าความเร็วตัด อัตราป้อนงาน และความเร็วรอบต่างๆ ลูกค้าพบว่าเครื่องมือกัด CoroMill Plura HD มีอายุการใช้งานนานกว่าถึง 253% เมื่อเทียบกับเครื่องมือกัดจากแบรนด์อื่น โดยที่คมตัดด้านนอกยังคงไม่มีการแตกบิ่นใดๆ

Article by: Sandvik Co., Ltd.

https://www.sandvik.coromant.com/th-th << Click Here