ทุกปี นักโลหะการจากทั่วโลกต่างตั้งตารอฟังผู้เชี่ยวชาญเครื่องมือตัดเฉือนโลหะ แสดงเทคโนโลยีใหม่ ๆ และปี 2025 ก็เป็นอีกครั้งที่ WALTER EWAG ภายใต้ชื่อ UNITED GRINDING Group เป็นเจ้าภาพจัดงาน Open House 2025 ที่สำนักงานใหญ่ในเมือง Tübingen โดยปีนี้ได้จัดแสดงนวัตกรรมล้ำสมัยที่ไม่เพียงขับเคลื่อนอุตสาหกรรมในปัจจุบันเท่านั้น แต่ยังกำหนดอนาคตของการตัดเฉือนเครื่องมือที่มีความแม่นยำ ระบบอัตโนมัติ และโซลูชันการบริการใหม่ด้วย

งานเริ่มต้นด้วยการนำเสนอประวัติอันยาวนานของ WALTER EWAG ซึ่งย้อนไปในปี พ.ศ. 2462 เมื่อ Richard Walter ก่อตั้งบริษัท “Montanwerke Walter” และมองเห็นความสำเร็จระดับโลกของบริษัทในฐานะผู้จัดหานวัตกรรมให้กับอุตสาหกรรมเครื่องมือ ประสบความสำเร็จที่สำคัญมากมายตลอดกว่าหนึ่งศตวรรษ ด้วยพนักงาน 600 คนและสาขาในกว่า 40 ประเทศทั่วโลก บริษัทได้รับการยอมรับอย่างสูงว่าเป็นผู้นำเทคโนโลยีด้านการเจียร การกัด การวัด และเลเซอร์ นอกจากนี้ WALTER EWAG ยังเป็นผู้ผลิตเครื่องเจียรเครื่องมือตัดรายเดียวที่นำเสนอเทคโนโลยีการวัด นับเป็นความแตกต่างจากบริษัทอื่น ๆ ในตลาด

งาน Open House 2025 ได้เน้นถึงพัฒนาการล่าสุดของ WALTER EWAG ใน 6 หัวข้อที่น่าสนใจดังนี้

การผลิตเครื่องมืออัตโนมัติ (ATP)

การผลิตเครื่องมืออัตโนมัติ (ATP) เป็นหนึ่งในดาวเด่นของงาน OPEN HOUSE ในปีนี้ เพื่อตอบสนองความต้องการด้านประสิทธิภาพในการทำงานและการขาดแคลนแรงงานทักษะ ซึ่งทำได้โดยการผสมผสานการตั้งค่าเครื่องจักร การชดเชยอัตโนมัติ และการควบคุมคุณภาพที่เชื่อมโยงกัน แนวคิดด้านความยืดหยุ่นและการใช้งานง่ายของระบบ ATP นำไปสู่การเปลี่ยนโฉมการผลิต เนื่องจากความง่ายในการนำไปใช้จริงในการผลิต

ด้วย RoboCell ของ ATP และหุ่นยนต์เคลื่อนที่ AMR ที่เชื่อมต่อเครื่องเจียร เครื่องกัด และเครื่องมือวัดเข้าด้วยกันอย่างไร้รอยต่อ ทำให้การผลิตอัตโนมัติเกิดขึ้นได้อย่างสมบูรณ์ นอกจากนี้ การผสมผสานนี้ยังง่ายต่อการปรับปรุงเพิ่มประสิทธิภาพได้อีก เครื่องจักร ทำงานโดยไม่มีดาวน์ไทม์ และมีพื้นที่สำหรับการโหลดชิ้นงานเข้าและออก ATP นำเสนอความสามารถในการปรับขนาดของเครื่องจักรที่มีอยู่โดยไม่ต้องเปลี่ยนไลน์การผลิต ปรับปรุงประสิทธิภาพ และลดรอบเวลาการทำงานให้สั้นลง

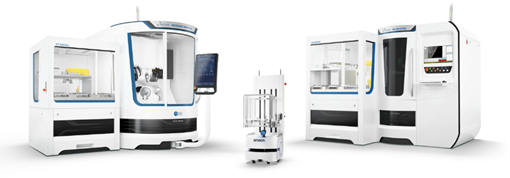

VISION LASER

เพื่อรับมือกระแสการใช้วัสดุคอมโพสิตเสริมเส้นใย และโลหะผสมน้ำหนักเบาในอุตสาหกรรมยานยนต์ และการบินและอวกาศเพื่อลดการใช้เชื้อเพลิง WALTER ขอแนะนำโซลูชันการตัดที่ให้ค่าความคลาดเคลื่อนที่เข้มงวดยิ่งขึ้น เพิ่มอายุการใช้งานเครื่องมือ การควบคุมกระบวนการ และความซับซ้อนของงาน เครื่องจักร WALTER ใหม่ที่เรียกว่า VISION LASER นำเสนอเทคโนโลยีเลเซอร์ที่เป็นนวัตกรรมใหม่ ได้รับการพิสูจน์ในอุตสาหกรรมและมีความน่าเชื่อถือสูง ให้ขอบตัดที่ปราศจากการแตกหัก พร้อมการหักเศษ และคุณภาพพื้นผิวที่เหนือกว่า เป็นทางเลือกที่คุ้มต้นทุนแทนวิธีการกัดด้วยลวด ออกแบบมาให้สามารถตัดวัสดุที่มีความแข็งเป็นพิเศษได้อย่างรวดเร็วและมีประสิทธิภาพในขณะที่เป็นมิตรต่อสิ่งแวดล้อม ไม่จำเป็นต้องใช้วัสดุสิ้นเปลือง เช่น ลวด สารหล่อลื่นหล่อเย็น

HELICHECK NANO

HELICHECK NANO เครื่องวัดตัวแรกของโลกที่ออกแบบมาเพื่อรองรับความต้องการที่เพิ่มขึ้นสำหรับเครื่องมือขนาดเล็กและขนาดนาโนในอุตสาหกรรมอิเล็กทรอนิกส์ การทำแม่พิมพ์ และเทคโนโลยีทางการแพทย์ HELICHECK NANO มาพร้อมระบบไฟแบ็คไลท์คู่ กล้องความละเอียดสูง และป้อมปืนสำหรับกล้องจุลทรรศน์ ทำให้สามารถวัดซ้ำได้และมีความแม่นยำระดับต่ำกว่า 0.5 ไมครอน เป็นการกำหนดมาตรฐานอุตสาหกรรมใหม่สำหรับการควบคุมคุณภาพของเครื่องมือที่มีเส้นผ่านศูนย์กลางเล็กถึง 0.1 มม.

Fire Stop & Go

การแนะนำฟีเจอร์ Fire Stop & Go ที่ออกแบบมาเพื่อความปลอดภัยที่เชื่อถือได้สำหรับเครื่องจักรกัดกร่อนของ WALTER คุณสมบัติพิเศษนี้ช่วยแก้ปัญหาความเสี่ยงจากไฟไหม้ในเครื่องจักรกัดด้วยลวดที่มีมาช้านาน วงจรการทำงานคือ เมื่อตรวจพบไฟไหม้ แหล่งต้นเหตุของไฟ เช่น สารหล่อเย็น และแกนหมุนจะถูกปิดทันที เมื่อการวิเคราะห์ Fire Stop & Go เสร็จสมบูรณ์ เครื่องกำเนิดไฟ สารหล่อเย็น และแกนหมุนจะถูกเปิดขึ้นมาอีกครั้ง และกระบวนการกัดด้วยลวดจะเริ่มต้นใหม่ คุณสมบัติเหล่านี้สร้างความปลอดภัยให้ลูกค้า รวมถึงผลผลิตที่เพิ่มขึ้นเนื่องจากเวลาหยุดทำงานที่ลดลง การประหยัดต้นทุนเนื่องจากเครื่องจักรได้รับความเสียหายจากไฟไหม้น้อยลง และการประหยัดต้นทุนและทรัพยากรเนื่องจากไม่สิ้นเปลืองขวด CO2

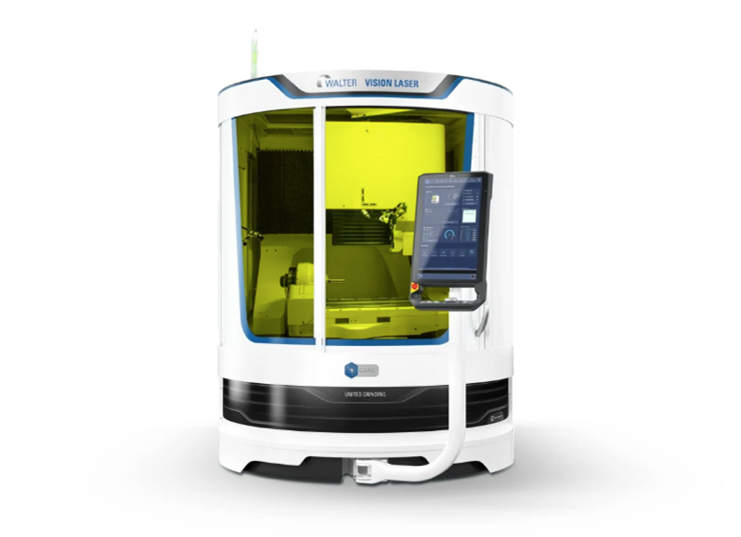

HELITRONIC RAPID

ในงานยังมีการจัดแสดง HELITRONIC RAPID เครื่องเจียรเครื่องมือระดับเริ่มต้นรุ่นใหม่ของ WALTER EWAG ที่ควบคุมด้วย CNC 5 แกนสำหรับการลับคมและการผลิตเครื่องมือโดยเฉพาะ ออกแบบมาสำหรับเครื่องมือขนาดเล็กเส้นผ่านศูนย์กลางตั้งแต่ 1 ถึง 16 มม. สำหรับการผลิต และ 3 ถึง 100 มม. สำหรับการลับคมใหม่ ความยาวการกลึงสูงสุดถึง 255 มม. และน้ำหนักสูงสุดถึง 30 กก. นับเป็นโซลูชันที่คุ้มต้นทุนสำหรับผู้ประกอบการที่ต้องการเข้าสู่ตลาดด้วยเงินทุนเริ่มต้นที่ไม่สูง

โปรแกรมการบำรุงรักษา WE CARE และพอร์ทัลลูกค้า

ช่วงท้ายของงานมีการนำเสนอสองฟีเจอร์ที่น่าสนใจ ได้แก่ โปรแกรมการบำรุงรักษา WE CARE และ พอร์ทัลลูกค้า โดยโปรแกรม We Care นำเสนอตัวเลือกการบำรุงรักษาที่หลากหลายให้กับลูกค้า รวมถึงแพ็คเกจพื้นฐานและแพ็คเกจเสริม ไฮไลท์ของโปรแกรมการบำรุงรักษา ได้แก่ การประเมินเรขาคณิตแบบดิจิทัล การวัดเพลาด้วยลายนิ้วมือ การจัดเก็บข้อมูลการวัดบนเครื่องจักรของลูกค้า และการแสดงภาพการสึกหรอโดยการเปรียบเทียบการวัดหลาย ๆ ครั้ง

สุดท้ายแต่สำคัญไม่แพ้กัน นั่นคือ Transaction Network ซึ่งเป็นแพลตฟอร์มของผู้ผลิตที่ช่วยแก้ปัญหาความไม่สะดวกทั่วไปจากการมีหลายพอร์ทัลสำหรับเครื่องจักรที่แตกต่างกัน ออกแบบมาเพื่อความคล่องตัวในการจัดการทรัพย์สิน เข้าถึงเอกสารทางเทคนิค และกระบวนการจัดซื้อ

จากสารประโยชน์ สู่การปฏิบัติ

งานโอเพนเฮาส์ของ WALTER EWAG ในปี 2025 ไม่เพียงแต่มาพร้อมกับนวัตกรรมล่าสุดและการอัปเดตเทคโนโลยีที่เป็นประโยชน์ต่อช่างโลหะการและผู้คนในวงการนี้เท่านั้น แต่ยังสะท้อนถึงความเข้าใจอย่างลึกซึ้งเกี่ยวกับแนวโน้มตลาดและความต้องการของลูกค้าอีกด้วย ตั้งแต่การแก้ไขปัญหาการขาดแคลนแรงงานผ่านการผลิตเครื่องมืออัตโนมัติ (ATP) ที่ทันสมัยที่สุด ไปจนถึงการขยายขอบเขตของความแม่นยำในการวัดเครื่องมือขนาดเล็ก และฟีเจอร์ด้านความปลอดภัยสำหรับเครื่องจักรกัดด้วยลวด บริษัทได้วางตำแหน่งตัวเองให้เป็นผู้นำในอุตสาหกรรมการผลิตเครื่องมืออย่างแท้จริง

นอกจากงานครั้งนี้จะนำเสนอโดยวิทยากรผู้เชี่ยวชาญอย่างแท้จริงแล้ว ความกระตือรือร้นของท่านก็น่าชื่นชมไม่แพ้กัน ขอขอบคุณ WALTER EWAG สำหรับความพยายามทั้งหมดเพื่อทำให้ Open House 2025 เป็นงานที่จดจำ แล้วพบกันใหม่ใน Open House 2026

ข้อมูลเพิ่มเติมเกี่ยวกับ WALTER EWAG Open House 2025 ได้ที่

www.walter-machines.com

Article by: MEGA Tech & W.P. P. Engineering Co., Ltd. < Click Here