เครื่องจักรกลนับว่าเป็นกลไกสำคัญในการกำหนดขีดความสามารถทางการผลิตสินค้าในภาคอุตสาหกรรมระดับโลก ทั้งด้านคุณภาพและปริมาณ โดยเครื่องจักรที่มีเทคโนโลยีขั้นสูงสามารถสร้างความได้เปรียบทางการแข่งขันให้กับผู้ผลิตได้อย่างดียิ่ง โดยเฉพาะในยุคของการเปลี่ยนแปลงเทคโนโลยีในระดับ Mega Trend ทั้ง Internet of Thing, Automation, Robotics, Artificial Intelligence, Virtual Reality, 3D Printing และ Electric Vehicle เป็นต้น

นิตยสาร MEGA Tech ฉบับนี้ มอบความพิเศษส่งท้ายปีด้วยบทสัมภาษณ์ของผู้ผลิตเครื่องจักรกลสัญชาติญี่ปุ่นทั้ง 4 ท่าน ซึ่งเป็นการรวมตัวกันครั้งแรกในฐานะของผู้ผลิตเครื่องจักรกลด้วยนวัตกรรมที่สอดรับและก้าวไปพร้อมกับ MegaTrend ของโลก ทั้ง MAZAK (THAILAND) CO., LTD., MITSUBISHI ELECTRIC AUTOMATION (THAILAND) CO., LTD., OKUMA TECHNO (THAILAND) LTD. และ TAKAMATSU MACHINERY (THAILAND) CO., LTD. โดยทั้ง 4 แบรนด์ได้เผยถึง Core Technology และผลิตภัณฑ์อันล้ำสมัยที่จะนำเสนอในช่วงปลายปีนี้ให้ได้รับทราบอย่างพร้อมเพรียงกัน

Core Technology Solution: The Way Forward to the World’s Industrial Trends

General Manager MAZAK (THAILAND) CO., LTD.

ซีรี่ส์ INTEGREX Advanced Multitasking กลายเป็นเครื่องจักรสำหรับยุคปัจจุบัน เหมาะกับการขึ้นรูปชิ้นงานที่มีความซับซ้อนสูง โดยเครื่องนี้เป็นการหลอมรวมความสามารถของเครื่องกลึงพลังสูงเข้ากับเครื่องแมชชีนนิ่งเซ็นเตอร์ที่มีฟังก์ชั่นครบครัน ในช่วงไม่กี่ปีที่ผ่านมาเราได้พัฒนาเครื่อง Multitasking แบบไฮบริดภายใต้แนวคิดขั้นสูง DONE-IN-ONE (การรวมกระบวนการ) โดยผสมผสานเทคโนโลยีการประมวลผลยุคใหม่เข้ากับเทคโนโลยี Multitasking ให้จัดการงานทั้งหมดได้ภายในเครื่องเดียว ในฐานะผู้วิจัยที่มุ่งมั่นในการพัฒนาการผลิตเครื่องจักรแบบ Multitasking รุ่นใหม่ที่ยกระดับขึ้นอีกขั้น ซึ่งรวมการทำงานแบบ Multitasking ที่หลากหลายพร้อมกับนวัตกรรมของระบบปฏิบัติการรุ่นใหม่ เช่นเทคโนโลยีการตัดโลหะ เทคโนโลยีการเชื่อมด้วยแรงเสียดทาน และเทคโนโลยีการผลิตระบบส่งกำลังประเภทเฟืองและเกียร์

บริษัทของเราเป็นหนึ่งในผู้ผลิตเครื่องจักร และเครื่องไฟฟ้าชั้นนำของโลกที่มีธุรกิจหลากหลายตั้งแต่เครื่องใช้ไฟฟ้าภายในบ้านไปจนถึงยานอวกาศ เรากำลังพัฒนาธุรกิจระดับโลกใน 5 หมวดธุรกิจได้แก่ อุตสาหกรรมหนัก เมคคาทรอนิกส์ ระบบสื่อสารโทรคมนาคม อุปกรณ์อิเล็กทรอนิกส์ และเครื่องใช้ไฟฟ้าภายในบ้าน ในบรรดาธุรกิจของเราที่มีวิวัฒนาการจากการผลิตมอเตอร์เอนกประสงค์และผลิตภัณฑ์ FA ของ Mitsubishi Electric ที่รองรับการผลิตของโลกมานานกว่า 90 ปี ดังนั้น จากการสั่งสมเทคโนโลยีและนวัตกรรมทางด้านระบบควบคุมเครื่องจักร ระบบเมคคาทรอนิกส์ และเทคโนโลยีการผลิต ทำให้เราพัฒนาสินค้า และขยายกลุ่มผลิตภัณฑ์ธุรกิจออกไปได้หลายสาขาอย่างต่อเนื่อง

ด้วยการเปิดตัวเครื่องจักรซีรี่ส์ใหม่ด้วยเทคโนโลยี Mitsubishi Electric AI (Maisart) และอุปกรณ์ควบคุมล่าสุด (D-CUBES) มีฟังก์ชั่นการใช้งานที่ยอดเยี่ยมทั้งความแม่นยำและผลผลิตที่สูงขึ้น นอกจากนี้ยังนำเสนอโซลูชั่น e-F@ctory, IQ Platform ที่มาพร้อมอุปกรณ์เชื่อมต่อข้อมูลในทุกระดับที่ช่วยรังสรรค์โรงงานอัจฉริยะได้เร็วก่อนใคร ในฐานะของซัพพลายเออร์อันดับ 1 ในธุรกิจ FA เราภูมิใจนำเสนอผลิตภัณฑ์ที่หลากหลายไประดับสากลเพื่อให้สามารถตอบโจทย์ความต้องการของลูกค้าในยุคไอทีมากที่สุด

Managing Director OKUMA TECHNO (THAILAND) LTD.

ในอดีต กระแสหลักของกระบวนการผลิตจะมีการกรุ๊ปรวมกระบวนการหลาย Process เพื่อขึ้นรูปชิ้นงานให้แล้วเสร็จด้วยเครื่องจักรขึ้นรูปหลายภาระกิจชนิด Multitasking เพียงเครื่องเดียว แต่สำหรับ OKUMA นอกจากจะมีทางเลือกของเครื่อง Multitasking อัจฉริยะที่สามารถกัด กลึง เจาะ ตัดแต่งชิ้นงานโลหะมีความซับซ้อน, กระบวนการแมชชีนนิ่งที่มีความแม่นยำสูง, การเจียระไน และชุบแข็งชิ้นงานด้วยความครบครันของบรรดาเทคโนโลยีโลหะที่ทำได้ในเครื่องเดียวกัน

OKUMA กำลังพัฒนานวัตกรรมและเทคโนโลยีสมัยใหม่ที่มีการผสมผสานกระบวนการขึ้นรูปชิ้นงานที่มีความแม่นยำขั้นสูงต่อไป ทั้งนี้ เพื่อตอบโจทย์การผลิตที่มีประสิทธิภาพมากยิ่งขึ้นให้กับลูกค้าของเรา

Managing Director TAKAMATSU MACHINERY (THAILAND) CO., LTD.

ผลิตภัณฑ์ของเราเป็นเครื่องจักรญี่ปุ่นคุณภาพสูง จนเป็นที่รู้จักในนาม “เครื่องที่หารายได้เก่ง” ในทุกยุคสมัย ด้วยผลงานจริงที่เราสามารถส่งมอบสินค้าหลัก ‘X-series’ ของ Takamatsu ไปแล้วกว่า 90% ของลูกค้าในกลุ่มอุตสาหกรรมยานยนต์ เพื่อตอบสนองต่อแนวโน้มและวิวัฒนาการของโลกด้วยระบบโหลดงานอัตโนมัติของทาคามัตสึที่เร็วขึ้น เรานำเสนอเครื่องจักรที่ทันสมัยพร้อมระบบต่อพ่วงเครื่องจักรที่ช่วยพัฒนาคุณภาพสินค้า เน้นการจัดการควบคุม “การผลิตจำนวนมาก” เป็นหลักเพื่อรองรับตามความต้องการของลูกค้า

Key Success: Performing the World’s Leading Machine Tools Maker

General Manager MAZAK (THAILAND) CO., LTD.

สิ่งสำคัญที่สุดคือ การตั้งโชว์รูมที่อยู่ใกล้ที่ตั้งของลูกค้าเพื่อการตอบรับด้วยความรวดเร็ว นับตั้งแต่มีการก่อตั้งบริษัท MAZAKได้ก้าวไปสู่ยุคโลกาภิวัฒน์โดยการพัฒนาโรงงานฐานการผลิตเครื่องจักร และสำนักงานเซอร์วิสเพื่อให้บริการลูกค้าทั่วโลกก่อนใคร ในอนาคตเราจะยังคงให้บริการนำเสนอผลิตภัณฑ์ที่เป็นนวัตกรรมใหม่ๆ พร้อมเทคโนโลยีการเพิ่มประสิทธิภาพการผลิตผ่านฐานการผลิตของเราไปทุกประเทศทั่วโลก ด้วยความมุ่งมั่น และหัวใจพัฒนาภายใต้คอนเซ็ป “โมโนทสึคุริ” ร่วมกับลูกค้าของเราที่อยู่ทั่วทุกมุมโลก

นโยบายการขายของเราคือ การพัฒนาความพึงพอใจของลูกค้าผ่านการยกระดับการบริการลูกค้าให้ดียิ่งขึ้นอีกขั้น นอกจากการนำเสนอผลิตภัณฑ์ล่าสุดที่มีประสิทธิภาพสูงแล้ว เรายังเชื่อว่าการรักษาขีดจำกัดในการใช้งานได้สูงของผลิตภัณฑ์จะนำไปสู่ความพึงพอใจของลูกค้าที่สูงขึ้น ด้วยเหตุนี้เราจึงคิดค้นประสิทธิภาพการตัดเฉือนโลหะด้วยเครื่องจักรที่ล้ำสมัยพร้อมๆ กับการนำระบบการจัดการข้อมูลแบบรวมศูนย์โดยการสร้างคอลล์เซ็นเตอร์ การแสดงผลสถานะและผลลัพธ์การผลิตได้แบบเรียลไทม์โดยใช้เทคโนโลยี IOT การปรับปรุงกระบวนการผลิต และความมุ่งมั่นในการลดต้นทุนการผลิตจากการบำรุงรักษาที่คาดการณ์ล่วงหน้า

นอกจากนี้ บริษัทมีความพยายามให้การเพิ่มความพึงพอใจของลูกค้าโดยจัดการฝึกอบรมสนับสนุนและให้คําปรึกษาแก่ลูกค้าเพื่อเพิ่มประสิทธิภาพของผลิตภัณฑ์ การส่งวิศวกรที่เชี่ยวชาญและมากประสบการณ์จากญี่ปุ่นไปเยี่ยมลูกค้า รวมถึงการแนะนำเทคโนโลยีและนวัตกรรมล่าสุดในญี่ปุ่นให้กับลูกค้าของเรา

Managing Director OKUMA TECHNO (THAILAND) LTD.

ในปี พ.ศ. 2563 บริษัทโอคุม่าจะฉลองครบรอบ 20 ปีในก่อตั้งบริษัท OKUMA TECHNO THAILAND ในประเทศไทย บริษัทมีทีมงานวิศวกรที่มีความชำนาญในด้านการบริการซ่อมบำรุงเครื่องจักรมากกว่า 20 คน

ด้วยการให้บริการที่รวดเร็วทั้งในภาษาไทยและภาษาญี่ปุ่น รวมถึงการให้บริการลูกค้าในการทดลองตัดเฉือนชิ้นงาน (TEST CUT) เพื่อให้มั่นใจว่าสินค้าที่ผลิตนั้นได้คุณภาพตามความต้องการก่อนตัดสินใจซื้อเครื่องจักร จนทำให้เราได้รับความเชื่อถือไว้วางใจจากลูกค้าเป็นอย่างมาก สิ่งที่สำคัญที่สุดในฐานะผู้ผลิตเครื่องจักรที่นอกเหนือไปจากการสนับสนุนข้อเสนอทางเทคนิค และนำเสนอเครื่องจักรที่ทันสมัยเพื่อตอบโจทก์ของลูกค้าแล้ว คือความรับผิดชอบที่มีต่อลูกค้า การให้ความใส่ใจ ความร่วมมือเมื่อลูกค้าประสบปัญหาในการขึ้นรูปชิ้นงาน ความมุ่งมั่นที่จะไม่ทำให้กระบวนการผลิตของลูกค้าต้องหยุดชะงักลง หรือไม่สามารถทำการรันได้อย่างมีประสิทธิภาพ ตลอดจนความช่วยเหลือเพื่อให้ลูกค้าสามารถใช้งานเครื่องจักรได้อย่างคุ้มค่า เต็มกำลังความสามารถของเครื่องจักรนั่นเอง

Managing Director TAKAMATSU MACHINERY (THAILAND) CO., LTD.

ไม่ว่าผลิตภัณฑ์เครื่องจักร หรือระบบควบคุมต่างๆ จะดีเพียงใด เครื่องจักรมักจะมีปัญหาในระหว่างการใช้งานเสมอ จากการเจราจาทางธุรกิจ บริษัทจะได้รับคำถามด้านงานบริการซ่อมบำรุงรักษาเครื่องจักรอยู่เสมอ เพื่อเป็นการสร้างระบบการทำงานที่ทำให้ลูกค้ามั่นใจในการตอบสนองความต้องการ รวมถึงจัดหาอะไหล่ได้อย่างรวดเร็ว บริษัทเราได้จัดตั้งสำนักงานจำหน่ายไว้ 2 แห่งในประเทศไทยทั้งในกรุงเทพ จังหวัดระยอง และในภูมิภาคอาเซียนมีสำนักงานขายในเวียดนามและอินโดนีเซีย

The Advance Technology: to Enhance Thailand’s Productivity in Manufacturing Industries

มีการคาดการณ์ว่าในอนาคตอันใกล้อัตราการเกิดที่ลดลงและจำนวนประชากรสูงอายุที่เพิ่มขึ้นในประเทศไทยจะก่อให้เกิดปัญหาการขาดแคลนแรงงานเหมือนกับประเทศญี่ปุ่น อีกทั้ง เมื่อเร็ว ๆ นี้ได้มีการกล่าวถึงกันบรรดาคนหนุ่มสาวเริ่มตีตัวออกห่างจากภาคการผลิตจึงทำให้ความต้องการใน “ระบบอัตโนมัติ” เพิ่มมากขึ้นในหลากหลายอุตสาหกรรม ดังนั้นเพื่อรับมือกับสภาพการณ์ดังกล่าว MAZAK จึงนำ “TA (TURN ASSIST) Series” ระบบการกลึงอัตโนมัติมาเปิดตัวในงาน METALEX 2019 ในประเทศไทยเป็นครั้งแรก คุณลักษณะพิเศษของ TA Series นี้ คือ “การป้อนข้อมูลที่ง่ายดายไม่ซับซ้อน” เพียงแค่ป้อนข้อมูลชิ้นงานที่จะทำการกลึงลงไปในอุปกรณ์ NC ล่วงหน้าก็สามารถตั้งค่า Robot ได้โดยง่าย

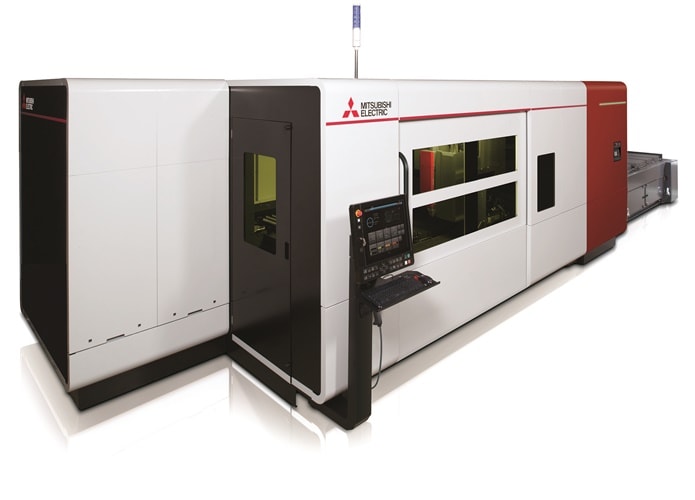

บริษัทจะวางจำหน่ายเครื่องไฟเบอร์เลเซอร์รุ่นใหม่ ซีรีย์ “ GX-F” สำหรับตัดชิ้นงานแบบ 2 มิติที่ติดตั้งด้วยเทคโนโลยี AI (Maisart) ของมิตซูบิชิ, AI อัจฉริยะเครื่องแรกของโลกที่มีฟังก์ชั่นปรับเงื่อนไขการผลิตอัตโนมัติตามเสียงและแสงจากชิ้นงานที่รันอยู่บนเครื่องที่ช่วยเพิ่มความแม่นยำในการตัดชิ้นงาน นอกจากนี้ความสัมพันธ์ที่ยอดเยี่ยมระหว่างเครื่องตัดไฟเบอร์ กับตัวส่งสัญญาณผ่านเส้นใยแก้วนำแสงรุ่นใหม่ของมิตซูบิชิที่ให้ประสิทธิภาพที่สูงกว่า สามารถควบคุมการเร่งความเร็วเครื่องได้อย่างเหมาะสม ช่วยเพิ่มประสิทธิภาพการตัดโลหะแผ่น เพิ่มการบำรุงรักษาเครื่องจักรเพื่ออายุการใช้งานที่ยาวนานกว่า

สำหรับเครื่อง EDM จะมีการเปิดตัวเครื่องใหม่ล่าสุด “ซีรี่ส์ SV-P” ที่มาพร้อมเทคโนโลยี AI (Maisart) และอุปกรณ์ควบคุม D-CUBES ที่เป็นเอกสิทธิ์เฉพาะของมิตซูบิชิ เป็นรุ่นที่รวมทุกมิติทั้งแง่ความละเอียดสูง ความแม่นยำสูง และการเพิ่มผลผลิตที่สูงมาไว้ด้วยกันอย่างลงตัว การประมวลผลจากการรับรู้ข้อมูลสถานะการกัดชิ้นงานแล้วป้อนกลับไปยังระบบการควบคุมการกัดชิ้นงานด้วยไฟฟ้าแบบเรียลไทม์ โดยนำมาปรับเงื่อนไขการผลิตที่เหมาะสมที่สุดได้เองโดยอัตโนมัติทำให้ผลิตชิ้นงานได้เสถียรขึ้น เป็นผลให้สามารถขึ้นรูปชิ้นงานได้อย่างมั่นคงโดยไม่ต้องคอยปรับให้ยุ่งยากอีกต่อไป

เรานำเสนอการสร้างคุณค่าแบบใหม่โดยการหลอมรวมเข้าด้วยกันระหว่างเครื่องจักรความแม่นยำสูงเข้ากับเทคโนโลยีหุ่นยนต์และระบบอัตโนมัติ ประเทศไทยก็เหมือนกับญี่ปุ่นที่ก้าวเข้าสู่ยุคแรงงานมมีอายุมากขึ้น และต้นทุนค่าแรงที่เพิ่มสูงขึ้น ครั้งนี้โอคุม่าตั้งใจนำเสนอผลิตภัณฑ์ ARMROID ระบบหุ่นยนต์ล้ำยุคกับเครื่องจักรอันทันสมัยสำหรับการทำงานอัตโนมัติที่มากกว่าเดิม

นอกเหนือจากการออกแบบเพื่อประหยัดพื้นที่ใช้งานแล้ว หุ่นยนต์ยังสามารถทำงานได้เหมือนกับเครื่องจักรอีกด้วย ในอดีตการสร้างโปรแกรมการทำงานของหุ่นยนต์ต้องใช้ฟังก์ชั่นพิเศษ และทักษะความรู้เฉพาะ เช่นใช้ภาษาโปรแกรมเฉพาะในการป้อนคำสั่งต่างๆ ซึ่งบางครั้งก็กลายเป็นปัญหาคอขวดในการนำไปใช้งาน แต่สำหรับ ROID ซีรีย์พร้อมระบบปฏิบัติการหุ่นยนต์แบบ ROS ระบบแรกของโลกที่ช่วยให้การทำงานของหุ่นยนต์ง่ายและปลอดภัยเพียงแค่ป้อนข้อมูลตามคำแนะนำ ท่านก็สามารถใช้งานได้โดยไม่ต้องมีผู้สอนหรือผู้วางระบบหุ่นยนต์

ภาพลักษณ์ของหุ่นยนต์อาจจะดูเหมาะกับโรงงานที่มีการผลิตแบบ Mass Production แต่ ROID ซีรีย์นี้ยังเหมาะสำหรับโรงงานที่รองรับการผลิตในแบบหลากหลายโมเดล ด้วยงานปริมาณน้อยชิ้นไปจนถึงหลายสิบชิ้นต่อวันเช่นเดียวกัน

ท่ามกลางภาวะเศรษฐกิจโลกที่มีแนวโน้มชะลอตัวลง ปริมาณการค้าของประเทศไทยซึ่งคาดว่าจะต้องสร้างขีดความสามารถในการแข่งขันกับฐานการผลิตกับประเทศอื่นๆ ในภูมิภาค รวมถึงหลายประเทศทั่วโลกที่พัฒนาแล้ว รวมถึงการรับมือกับปัญหาการขาดแคลนทรัพยากรมนุษย์ เพื่อเอาชนะตลาดในภาวการณ์แข่งขันกับคู่แข่งที่ทวีความรุนแรงขึ้นนั้นจึงจำเป็นต้องปรับปรุงกระบวนการผลิตให้มีประสิทธิภาพสูงขึ้น นำเทคโนโลยีล่าสุดมาใช้ให้มากกว่าที่เคยทำ รวมถึงในอนาคตอันใกล้กับความจำเป็นของประเทศไทยที่จะต้องปรับทัพอุตสาหกรรมให้เป็นหุ่นยนต์ และระบบอัตโนมัติให้ได้

ทาคามัตสึได้นำเครื่องจักรพร้อมระบบ LOADER มาวางจำหน่ายในประเทศไทยแล้ว โดยในงาน METALEX 2019 จะจัดแสดงสินค้าและเทคโนโลยีของระบบอัตโนมัติล่าสุดพร้อมรูปแบบการลดใช้แรงงานคน เช่น เครื่องจักรรุ่น XT-6