ตลาดหุ่นยนต์อุตสาหกรรมทั่วโลกยังคงเติบโตอย่างต่อเนื่อง สาเหตุหลักเนื่องจากขาดแคลนแรงงานตั้งแต่ช่วงระบาดของโควิด 19 เป็นต้นมา ข้อมูลจากเว็บไซต์ Statista (ปี 2023) ระบุว่าในช่วงปีอีกห้าปีข้างหน้า ตลาดหุ่นยนต์อุตสาหกรรมทั่วโลกจะมีมูลค่า 10.41 พันล้านดอลลาร์สหรัฐ

ในปฐมฉบับของปี 2525 MEGA Tech ขอเสนอแนวโน้มการพัฒนาและความก้าวหน้าของหุ่นยนต์อุตสาหกรรมที่เข้ามามีบทบาทในภาคการผลิตในอนาคตอันใกล้ ซึ่งก็คือหุ่นยนต์คล้ายมนุษย์ที่ขับเคลื่อนด้วยความก้าวหน้าของ AI

หุ่นยนต์ใหม่ที่ขับเคลื่อนด้วยพลัง AI

AI หรือปัญญาประดิษฐ์ได้เข้ามาปฏิวัติวงการหุ่นยนต์อุตสาหกรรม ทำให้หุ่นยนต์สามารถทำงานต่าง ๆ ที่เคยต้องพึงพามนุษย์ได้ AI ช่วยให้หุ่นยนต์อุตสาหกรรมสามารถทำงานซับซ้อนได้ เช่น การเชื่อม การประกอบ และการตรวจสอบโดยอัตโนมัติ เพิ่มความแม่นยำและลดข้อผิดพลาดของมนุษย์

AI ยังสามารถช่วยในการบำรุงรักษาเชิงคาดการณ์เพื่อลดดาวน์ไทม์ มันสามารถปรับตัวให้เข้ากับงานที่เปลี่ยนแปลงไปในสภาพแวดล้อมการผลิตที่มีความยืดหยุ่น ช่วยเพิ่มประสิทธิภาพการจัดการห่วงโซ่อุปทานด้วยการวิเคราะห์ข้อมูลแบบเรียลไทม์

ตัวอย่างหุ่นยนต์อุตสาหกรรมที่มีชื่อเสียง ได้แก่ หุ่นยนต์เดลต้าที่นำมาใช้สำหรับการหยิบและวางได้อย่างรวดเร็วในอุตสาหกรรมอาหาร ยา และอิเล็กทรอนิกส์ หุ่นยนต์แบบข้อต่อ (Articulated robots) เป็นหุ่นยนต์อุตสาหกรรมที่พบมากที่สุดในการผลิต โลจิสติกส์ อาหาร และการเกษตรกรรม ส่วนหุ่นยนต์คล้ายมนุษย์ เป็นหุ่นยนต์ที่ออกแบบมาเพื่อทำงานทดแทนแรงงานในสภาพ แวดล้อมต่าง ๆ เช่น โรงงานและโลจิสติกส์

ตัวอย่างการใช้ AI ในหุ่นยนต์อุตสาหกรรมที่น่าสนใจคือ บริษัท KUKA ซึ่งนำเสนอโซลูชันสำหรับอุตสาหกรรมต่าง ๆ เช่น การผลิตยานยนต์และการบินและอวกาศ โดยการผสาน ChatGPT ของ AI มาใช้ในการเขียนโปรแกรมหุ่นยนต์

“โดยส่วนใหญ่แล้ว การเขียนโปรแกรมหุ่นยนต์ยังคงเป็นงานสำหรับผู้เชี่ยวชาญ” โรแลนด์ ริตเตอร์ ผู้จัดการโปรแกรมแพลตฟอร์มจำลองของ KUKA กล่าว “นี่คือเหตุผลที่เรากำลังพัฒนาแชทบอท AI ที่จัดการแปลงคำสั่งเสียงมนุษย์เป็นโค้ดโปรแกรม จากนั้นโมเดล AI จะสร้างโค้ดที่ทำให้หุ่นยนต์ทำสิ่งที่ต้องการได้ อย่างเช่น หยิบชิ้นส่วนทีละชิ้นแล้ววางเป็นรูปตัว U บนโต๊ะ โมเดล AI จะได้รับการฝึกด้วยโปรแกรมหุ่นยนต์ทั้งหมดทีมี ในขั้นตอนถัดไป KUKA กำลังดำเนินการส่งต่อแชทบอท AI นี้ให้กับลูกค้าผู้ใช้งานหุ่นยนต์ เพื่อให้ลูกค้าสร้างคำสั่งให้กับหุ่นยนต์โดยใช้เสียงของตนแทนการเขียนโปรแกรมแบบเดิม

แต่ก่อนวิศวกรต้องเขียนโปรแกรมเพื่อสั่งหุ่นยนต์ทำงานในแต่ละขั้นตอนที่ต้องการ แต่ที่ Deep Mind บริษัทลูกของกูเกิลในลอนดอนบอกว่าเราไม่จำเป็นต้องเขียนคำสั่งหรือโปรแกรมอีกแล้ว หุ่นยนต์นักฟุตบอลนี้สามารถเรียนรู้ทักษะการเคลื่อนไหวได้เอง จากครั้งแรกที่มันเอาแต่วิ่งตามลูกบอลเหมือนเด็กหกขวบที่เล่นฟุตบอลเป็นครั้งแรก ผ่านไปสักระยะมันจะเรียนรู้ได้เองว่าจะเลี้ยงลูกหลบหลีกฝ่ายตรงข้ามอย่างไรเพื่อการทำประตู คำสั่งของมนุษย์ต่อหุ่นยนต์จึงเหลือเพียงประโยคเดียว คือ “ทำประตูให้มากที่สุด”

หุ่นยนต์คล้ายมนุษย์ เพื่อนร่วมงานคนใหม่

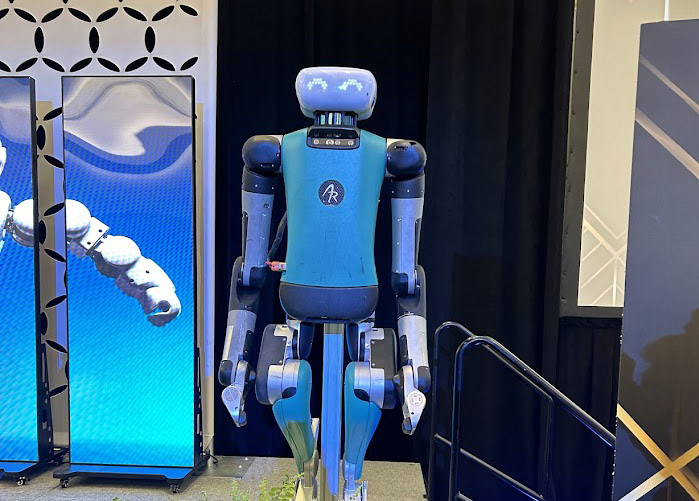

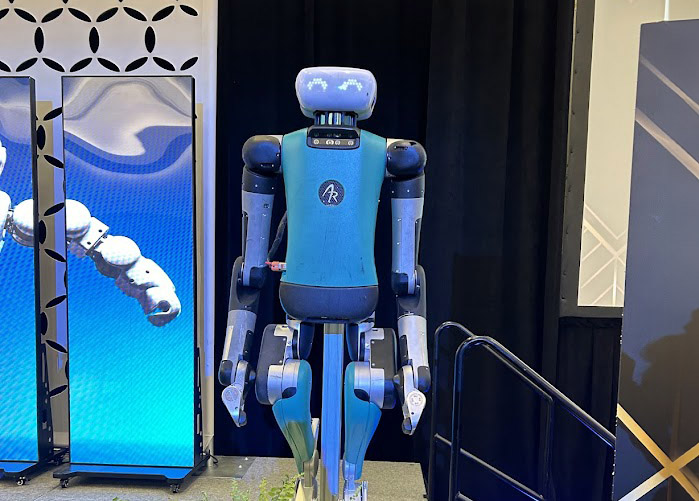

การหาคนงานมาทำงานในโรงงานผลิตและโลจิสติกส์นั้นเป็นเรื่องที่ยุ่งยากมาก “ปัจจุบันมีตำแหน่งงานว่างมากกว่าล้านตำแหน่ง ในสหรัฐอเมริกาซึ่งยังหาคนมาทำงานไม่ได้” เป็กกี จอห์นสัน ซีอีโอของ Agility Robotics กล่าว นั่นคือที่มาของหุ่นยนต์คล้ายมนุษย์ที่มีชื่อว่า ดิจิท (Digit) ของ Agility ซึ่งได้รับการฝึกฝนโดย AI เพื่อให้ทำงานได้ ซึ่งปัจจุบัน Digit กำลังทำงานอยู่ในบริษัทผู้ให้บริการโลจิสติกส์หลายแห่ง รวมถึงของ Amazon ด้วย จอห์นสันบอกอีกว่า“Agility เป็นบริษัทแรกที่นำหุ่นยนต์คล้ายมนุษย์มาใช้งานและได้รับเงินค่าจ้างจริงในการทำงาน และประมาณการว่าหุ่นยนต์จะสามารถทำงานคืนทุนภายในเวลาไม่ถึงสองปี แม้ว่าตอนนี้ ดิจิท ทำงานโดยยังต้องมีรั้วกั้นเพื่อความปลอดภัยของมนุษย์ แต่เธอหวังว่าหุ่นยนต์คล้ายมนุษย์จะทำงานเคียงข้างมนุษย์ได้ภายในปลายปี 2025 นี้

ดิจิทเป็นหนุ่นยนต์ที่เคลื่อนไหวด้วยสองขาและสองแขนแบบมนุษย์ โดยมีองศาอิสระ (DOF) 16 (ขา: 5 DoF x 2 และแขน: 3 DoF x 2) สามารถลุกขึ้นยืนจากพื้น ยกกล่อง รับน้ำหนักได้สูงสุด 16 กก. ทำงานด้วยเซ็นเซอร์ Lidar, ใช้กล้องที่วัดความลึกได้ของ Intel RealSense สี่ตัว, ตัวเข้ารหัสแบบสัมบูรณ์, การประมวลผลใช้ซีพียู Intel i7 มัลติเธรดสองตัว ใช้แบตเตอรี่ลิเธียมโพลิเมอร์ 1.2 กิโลวัตต์ชั่วโมงที่ออกแบบพิเศษ ส่วนวัสดุโครงสร้างหลักเป็นอลูมิเนียม โพลีคาร์บอเนตแบบเทอร์โมฟอร์มและคอมโพสิตคาร์บอนไฟเบอร์

Agility เปิดตัว ดิจิท ในปี 2019 และโรงงานผลิตหุ่นยนต์ดิจิทในโอเรกอนจะสามารถผลิตได้ 10,000 ตัวต่อปี เพื่อตอบสนองความต้องการหุ่นยนต์เร่งด่วนในสหรัฐ

ท่ามกลางความกังวลว่าหุ่นยนต์เหล่านี้มาแย่งงานแรงงานที่เป็นมนุษย์ เป็กกี จอห์นสันอธิบายว่า “หุ่นยนต์จะไม่แย่งงาน แต่จะแย่งภาระ” ความหมายคือ พนักงานที่เป็นคนจะไม่ต้องทำงานในส่วนที่เป็นกายภาพ แต่จะทำงานที่ใช้สมองและทักษะความสามารถในการบริหารจัดการ หากย้อนไปเมื่อหลายปีก่อน ในไลน์การผลิตเราจะนึกเห็นภาพพนักงานนั่งเรียงแถวเป็นแนวโดยมีสายพานลำเลียงชิ้นงานเพื่อให้พนักงานประกอบชิ้นส่วน และมีซูปเปอร์ไวเซอร์คอยควบคุมดูแลพนักงานเหล่านี้อีกที ในอนาคตพนักงานที่ประกอบชิ้นส่วนจะถูกทดแทนด้วยหุ่นยนต์ และตัวพนักงานที่เป็นมนุษย์จะไปทำหน้าที่ควบคุมดูแลฟลีต(ฝูง)หุ่นยนต์แทน

Article by: Asst. Prof. Suwan Juntiwasarakij, Ph.D., Senior Editor & MEGA Tech