Article by: Asst. Prof. Suwan Juntiwasarakij, Ph.D., Senior Editor

ผู้บริโภคคือผู้ที่ผลักดันนวัตกรรม ณ ใจกลางของเครือข่ายอุปสงค์ ผู้บริโภคเป็นมากกว่าผู้รับสินค้า ณ ปลายทางของของห่วงโซ่อุปทาน โมเดลห่วงโซ่อุปทานดังเดิมแบบเชิงเส้นจึงถูกท้าทายความเปลี่ยนแปลงที่เกิดขึ้นในรากฐานโครงสร้างกับโมเดลดังเดิมเหล่านี้ ก็เพราะผู้ประกอบการธุรกิจทั้งหลายต่างก้าวเข้าสู่เครือข่ายอุปทานที่มีความซับซ้อนสูง ขับเคลื่อนด้วยข้อมูล และขับเคลื่อนด้วยผู้บริโภค การตอบสนองต่อรูปแบบการบริโภคที่เปลี่ยนไปจำเป็นต้องอาศัยระบบการผลิตแบบแมสที่ปรับแต่งได้คล่องตัว การวางแผนและการประสานภายในห่วงโซ่อุปทานที่มีความแม่นยำ และช่องทางการจัดจำหน่ายที่หลากหมายทั่วถึงและรวดเร็ว เหล่านี้เองที่ก่อเกิดนวัตกรรม เพื่อการบริการที่ดีพร้อม เพื่อการเติบของธุรกิจด้วยทุนต้นที่น้อยลง

Source: AI and Robotics Automation in Consumer-Driven Supply Chain, SPA Consulting Group

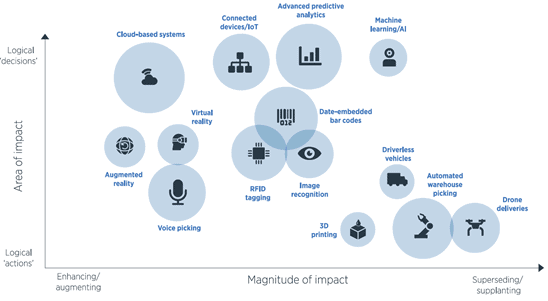

ความก้าวหน้าด้านปัญญาประดิษฐ์ AI และระบบ Robotics Automation ที่เกิดขึ้นนี้เอง ที่จะเอาชนะอุปสรรคต่างๆ และรวมทั้งปฏิบัติวัติวงการห่วงโซ่อุปทาน แต่อย่างไรก็ดี ก็ไม่ได้ทำให้มนุษย์หมดความสำคัญลงเนื่องจากในปัจจุบัน ระบบกลไกเหล่านี้ยังไม่สามารถเผชิญหน้ากับปัญหาที่หนทางการรับมือแก้ไขอาศัยชุดความรู้และทักษะที่ยากต่อการถ่ายทอด ทำให้เทคโนโลยีและมนุษย์ยังคงมีความจำเป็นที่จะต้องทำงานร่วมกันเพื่อบรรลุเป้าหมายของงานในอุตสาหกรรม Logistics ในปัจจุบันและในอนาคต

Source: Artificial Intelligence in Logistics, DHL

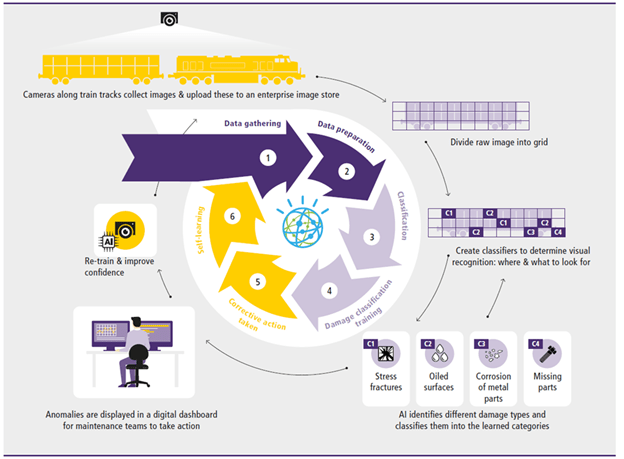

ความก้าวหน้าทางด้าน Computer Vision ทำให้มนุษย์ได้เห็นและทำความเข้าใจโลกในมุมมองใหม่เช่นเดียวกับที่เกิดขึ้นกับกระบวนการทาง Logistics การตรวจสอบด้วยตาที่เสริมด้วยเทคโนโลยี AI เป็นอีกแนวทางหนึ่งที่นำมาใช้ในกระบวนการทาง Logistics ได้ ตัวอย่างเช่น ได้มีการนำเอาความสามารถด้านการระลึกรู้จำทางการมองเห็นของเครื่อง IBM Watson มาใช้ในงานบำรุงรักษาทรัพย์สินซึ่งเทคโนโลยีเรียกว่า “AI-Driven Visual Inspection” ไม่ว่าจะเป็นอุตสาหกรรม Logistics เองก็ดี หรือในอุตสาหกรรมต่างๆ ล้วนประสบกับปัญหาความชำรุด เสียหายที่เกิดขึ้นกับอุปกรณ์เครื่องมือที่เกิดขึ้นตามกาลเวลาและการใช้งาน ใช้เพียงภาพถ่ายยานพาหนะขนส่งสินค้าที่ได้รับจากกล้อง IBM Watson ก็สามารถระบุพิกัดความเสียหาย แยกแยะประเภทของความเสียหาย รวมทั้งกำหนดวิธีซ่อมแซ่มบำรุงรักษาที่เหมาะสมให้แก่สินทรัพย์ได้อีกด้วย

Source: Artificial Intelligence in Logistics, DHL

การตรวจสอบสินทรัพย์ด้วยเทคโนโลยี AI นี้สามารถทำได้โดยเริ่มจากการติดตั้งกล้องไว้ที่รางรถไฟซึ่งจะถ่ายภาพตู้ขนสินค้าเก็บไว้ขณะที่รถไฟวิ่งผ่าน ภาพเหล่านี้จะถูกอัพโหลดไปที่ IBM Watson ซึ่งจะมี AI ที่ทำหน้าที่ระบุชี้ความเสียหายบริเวณที่เกิดความเสียหายบนตู้ขนสินค้า ซึ่ง AI ตัวดังกล่าวนี้ได้รับการฝึกฝนมาเพื่อให้ระลึกรู้ถึงชิ้นส่วนองค์ประกอบของตู้ขนสินค้าและสามารถที่จะแยกแยะจัดหมวดหมู่ความเสียหายที่พบทั้ง 7 ประเภท ยิ่งมีข้อมูลภาพมากขึ้นเท่าไหร่ การทำงานของ Watson ก็พัฒนามากขึ้นเท่านั้น จนกระทั่งสามารถทำงานได้ด้วยความแม่นย่ำสูงถึง 90% ได้ในเวลาอันสั้น ความผิดปกติที่ถูกตรวจพบโดย Watson จะถูกส่งต่อไปยังทีมบำรุงรักษา รูปแบบและกระบวนการเช่นนี้สามารถนำไปใช้ประยุกต์ใช้ได้กับสินทรัพย์ Logistics ประเภทอื่น ไม่ได้จำกัดอยู่เพียงงานอากาศยาน งานยานพาหนะ และงานเรือเดินทะเล

Source: IGD Supply Chain Analysis

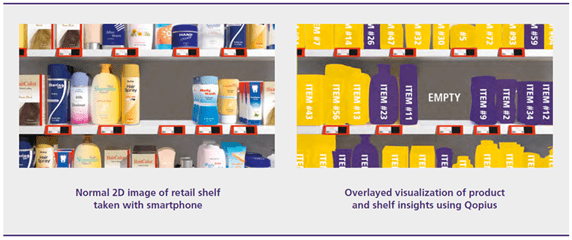

ไม่เพียงเฉพาะแต่ธุรกิจ Logistics ขนาดใหญ่เท่านั้น ผู้ประกอบการค้าปลีกก็สามารถที่จะได้รับประโยชน์จากความก้าวหน้าของ AI ได้เช่นกัน เมื่อไม่นานมา Qopius บริษัทสตาร์ทอัพสัญชาติฝรั่งเศสได้พัฒนาระบบ Computer Vision ด้วยเทคโนโลยี AI สำหรับตรวจสอบติดตามสินค้าเพื่อการบริหารงานร้านค้าปลีก Qopius ผสานเทคโนโลยี Machine-Learning และ การระลึกรู้ภาพความละเอียดสูง จึงสามารถสกัดรายละเอียดของสินค้าไม่ว่าจะเป็นยี่ห้อ ป้ายฉลาก โลโก้ ราคา และสถานภาพของสินค้าบนชั้นวางสินค้าไม่ว่าจะเป็นการวางสินค้าบนสั้น สินค้าหมดจากชั้น สินค้าคงเหลือบนชั้น เทคโนโลยี Computer Vision AI ดังกล่าวนี้สามารถนำไปใช้ในงานบริหารคลังสินค้าแบบ Real-Time ได้ในระดับ SKU ระดับชิ้นต่อชิ้น

Source: Qopius

นอกจากนี้แล้ว TwentyBN บริษัทสตาร์ทอัพในแคนาดากำลังพัฒนาศึกษาวิจัย Deep-Learning AI ให้มีความสามารถถอดรหัสพฤติกรรมที่มีความซับซ้อนของมนุษย์ที่จากภาพวิดิโอ ตัวอย่างการประยุกต์ใช้เทคโนโลยีประเภทนี้ได้แก่ ระบบตรวจจับการหกล้มของผู้สูงอายุ พฤติกรรมก้าวร้าวบนระบบขนส่งมวลชน และการขโมยของในร้านค้า ในปัจจุบันมีการใช้กล้องวิดิโอรักษาความปลอดภัยอยู่เป็นจำนวนนับนับไม่ถ้วนในคลังสินค้าอยู่แล้ว เมื่อนำมาผนวกเข้ากับเทคโนโลยี AI ในลักษณะนี้แล้วสามารถนำเพิ่มประสิทธิภาพการทำงาน หรือเพิ่มความปลอดภัยในการทำงานได้

ชัดเจนว่าอนาคตของ AI ในงาน Logistics นั้นสว่างไสวและทรงพลัง ขณะที่ผู้เล่นนำในห่วงโซ่อุปทานเดินหน้าสู่เส้นทาง Digital Transformation AI จะมีความสำคัญมากขึ้นและกลายมาเป็นกิจวัตรทางธุรกิจ ปรากฎการณ์เหล่านี้เร่งรัดพลักดันงาน Logistics ให้มีความว่องไว ความน่าเชื่อถือไว้วางใจได้ ความเป็นอัตโนมัติ และความสามารถในการปรับแต่งต่อไปในอนาคต แท้ที่สุดแล้ว AI จะสามารถทดแทนการพึ่งพาความสามารถในระดับสัญชาติญาณของมนุษย์ ทำให้มนุษย์เป็นอิสระจากพันธนาการ เพื่อสร้างสรรค์สิ่งที่มีความหมายต่อไป