ในปัจจุบันผู้ประกอบการต่างต้องการลดการผิดพลาดของชิ้นงานที่จะเกิดขึ้นในกระบวนการผลิต ซอฟต์แวร์ เป็นหนึ่งในส่วนสำคัญที่สามารถช่วยให้การผลิตของคุณมีประสิทธิภาพสูงสุด ด้วยระบบวิเคราะห์มาตรวัดแบบอัตโนมัติที่สามารถสร้างการเปลี่ยนแปลงในองค์กรของคุณ โดยให้ข้อมูลแบบ Real Time เพื่อป้องกันการเกิดข้อผิดพลาดที่จะเกิดขึ้น และยังช่วยลดค่าใช้จ่ายได้

การวิเคราะห์ระบบมาตรวัดอัตโนมัติ (AMSA)

เพื่อให้ผู้จัดการฝ่ายผลิตสามารถสร้างการเปลี่ยนแปลงในองค์กรของตนเองได้ พวกเขาต้องสามารถเก็บและวิเคราะห์ข้อมูลอย่างมีประสิทธิผล และที่สำคัญคือต้องสามารถใช้ข้อมูลนี้เพื่อเพิ่มผลิตผลในระบบการผลิต

องค์กรควรมีระบบ “การเก็บข้อมูลตามเวลาจริง” เพื่อปรับปรุงประสิทธิภาพ ลดความผิดพลาดและลดค่าใช้จ่าย

นิยามพื้นฐานของข้อมูลตามเวลาจริง หมายถึง ข้อมูลที่ไม่ได้ถูกเก็บรักษาหรือสะสมไว้ แต่ข้อมูลถูกส่งต่อไปยังผู้ใช้ปลายทางอย่างรวดเร็วทันทีที่ได้รับข้อมูล ข้อมูลตามเวลาจริงมีความสำคัญมากต่อระบบบางอย่าง เช่น ระบบนำทางจีพีเอสซึ่งแสดงผลให้คนขับทราบว่ากำลังเกิดอะไรขึ้นรอบตัวรถ ข้อมูลตามเวลาจริงมีประโยชน์กับโครงการวิเคราะห์ทุกชนิดและช่วยให้ผู้ใช้ทราบสภาพแวดล้อมในภาวะปกติของตนเองผ่านการส่งมอบข้อมูลแบบทันที

ในปัจจุบันองค์กรหลายแห่งพบปัญหาในการเก็บและใช้ข้อมูลให้มีประสิทธิผลสูง ตอนนี้กลุ่มบริษัทเจเอสอาร์มีวิธีแก้ปัญหาที่ดีที่สุดสำหรับคุณแล้ว …

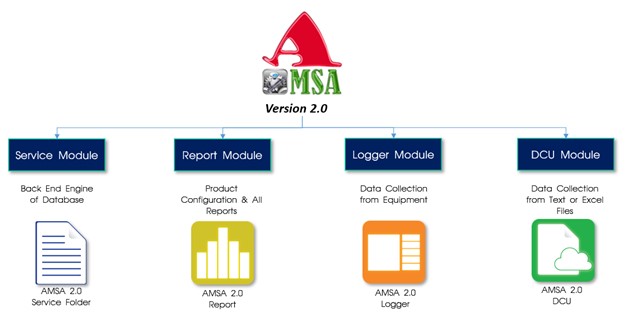

การวิเคราะห์ระบบมาตรวัดอัตโนมัติ (AMSA) คือ โปรแกรมการเก็บข้อมูลตามเวลาจริงซึ่งประกอบด้วย 4 กลไก

- โมดูลบริการ

- โมดูลรายงาน

- โมดูลบันทึกข้อมูล

ทำงานร่วมกับเครื่องมือขนาดเล็ก เช่น เครื่องวัดเวอร์เนียคาลิปเปอร์ ไมโครมิเตอร์ - หน่วยเก็บข้อมูล (DCU)

เก็บข้อมูลจากข้อความหรือไฟล์เอกซ์เซล

โมดูลบริการจะส่งข้อมูลไปที่โมดูลรายงานและรับข้อมูลจากโมดูลบันทึกข้อมูลและหน่วยเก็บข้อมูล กลไกนี้จะทำงานเป็นหน่วยพื้นฐานของระบบ

โมดูลรายงาน ใช้งานเพื่อวัตถุประสงค์ 2 ประการ

- ทำการตั้งค่าผลิตภัณฑ์ (เอกสารการควบคุมคุณภาพแบบอิเล็กทรอนิกส์)

- ทำรายงานสถิติพื้นฐาน เช่น แผนภูมิผลผลิตและพาเรโต รายงานความสามารถของกระบวนการผลิต (Cp&Cpk) การควบคุมกระบวนการผลิตด้วยหลักสถิติ (X-bar, R-Chart) และการวิเคราะห์แนวโน้ม (I-MR)

โมดูลบันทึกข้อมูลและหน่วยเก็บข้อมูล ทำหน้าที่เดียวกัน นั่นคือ เก็บข้อมูลจากพื้นที่การผลิตและส่งข้อมูลไปที่ฐานข้อมูล

ขั้นที่ 1: ทำเอกสารการควบคุมคุณภาพแบบอิเล็กทรอนิกส์และส่งไปที่ฐานข้อมูล

ตั้งค่าผลิตภัณฑ์โดย:

- กรอกข้อมูลในฐานข้อมูล

- ก็อปปี้แบบฟอร์มลูกค้าที่เป็นไฟล์เอกซ์เซลให้เป็นไฟล์สำหรับระบบ AMSA และโหลดไปที่ฐานข้อมูล (แนะนำ)

- ผลิตซ้ำจากผลิตภัณฑ์ที่มีอยู่เดิม (แนะนำสำหรับผลิตภัณฑ์รูปทรงเดียวกันแต่ขนาดต่างกัน)

ขั้นที่ 2: เรียกใช้แบบฟอร์มอิเล็กทรอนิกส์และข้อมูลที่เก็บในระบบโดยใช้โมดูลบันทึกข้อมูลหรือหน่วยเก็บข้อมูล และส่งข้อมูลไปที่ฐานข้อมูล

ขั้นที่ 3: เปิดฟังก์ชั่นรายงานเชิงสถิติเพื่อดูรายงานสถิติพื้นฐาน เช่น แผนภูมิผลผลิตและพาเรโต รายงานความสามารถของกระบวนการผลิต (Cp&Cpk) การควบคุมกระบวนการผลิตด้วยหลักสถิติ (X-bar, R-Chart) และการวิเคราะห์แนวโน้ม (I-MR)

ขั้นที่ 4: ส่งข้อมูลออกและใช้ฟังก์ชั่น Macro เพื่อทำรายงานที่เป็นไฟล์เอกซ์เซล

ตัวอย่างรายงาน: 1 รายงานสถิติพื้นฐานจากฐานข้อมูล

รายงานสถิติโดยละเอียด : การวิเคราะห์ระบบประมวลผลข้อมูล

เหตุผลที่ควรใช้ระบบ AMSA

ประโยชน์ในระดับพนักงาน

- ประหยัดเวลา (80%)

- ไม่มีความผิดพลาดที่เกิดจากมนุษย์

- ไม่ต้องใช้เอกสาร

- ไม่ต้องใช้พื้นที่เก็บกล่องเอกสาร

- ตรวจเช็คย้อนหลังได้ง่าย

- ทำรายงานโดยอัตโนมัติในรูปแบบที่คุณต้องการ

ประโยชน์สำหรับฝ่ายบริหาร

- ประเมินพนักงานทั้งหมดตามเวลาจริงด้วยมาตรวัดแบบต่างๆ [เช่น รายงานความสามารถของกระบวนการผลิต (Cp&Cpk) ค่าเบี่ยงเบนมาตรฐาน แผนภูมิผลผลิตและพาเรโต การควบคุมกระบวนการผลิตด้วยหลักสถิติ (Xbar-R) แผนภูมิแยก (I-MR)]

- คาดการณ์งาน NG

- เช็คผลการปฏิบัติงานของผู้ปฏิบัติงานทุกคน

- ติดตามผลตามเวลาจริง

- ส่งความเห็นจากฝ่ายควบคุมคุณภาพไปถึงฝ่ายผลิตตามเวลาจริง

- เพิ่มความน่าเชื่อถือจากลูกค้า

Article by: JSR Group & MEGA Tech

Reference: https://jsr.co.th/