ชิ้นส่วนที่ผลิตด้วยกระบวนการหล่อมีความสำคัญและใช้กันอย่างแพร่หลายในอุตสาหกรรม บทความนี้ทาง MEGA Tech ขอนำเสนอถึงการนำเครื่องสแกน 3 มิติ(3D Scanner) มาใช้เพื่อช่วยพัฒนาและยกระดับคุณภาพของชิ้นงานหล่อให้ดีขึ้น ซึ่งส่งผลต่อผลิตภาพและยกระดับคุณภาพการผลิตของโรงงานให้สูงขึ้นอีกด้วย

เครื่องสแกน 3 มิติ (3D Scanner) เป็นเครื่องมือที่ใช้วัดพื้นผิวของชิ้นงานแบบไม่สัมผัส (Non-contact) โดยวัดเป็นจุดพิกัดจำนวนมากบนผิวของวัสดุที่เรียกว่า คลาวด์พอยต์ (Cloud Point) หลังจากนั้นจะแปลงเป็นพื้นผิวเล็กหรือผิวเมช (Mesh) ผิวเมชจะเชื่อมต่อกันเป็นผิวของชิ้นงานที่สมบูรณ์และนำไปใช้งานทางวิศวกรรมต่อไป สามารถนำเครื่องสแกน 3 มิติ (3D Scanner)

มาใช้กับชิ้นงานหล่อได้ดังนี้

1. การลดความผิดพลาดในการผลิต

ในกระบวนการหล่อแม่พิมพ์จะประกอบไปด้วยชิ้นส่วนหลายๆชิ้น หรือจำเป็นต้องสัมพันธ์กับขนาดของแพทเทิร์น (Pattern) ขนาดที่ผิดพลาดจะส่งผลต่อขนาดของชิ้นงานหรือต้องทำการแก้ไขให้ถูกต้องก่อน ZEISS Inspect Pro สามารถตรวจวัดชิ้นส่วนต่างๆได้ก่อน เช่น แม่พิมพ์ทราย ชิ้นส่วนคอร์ว่ามีขนาดรูปร่างถูกต้อง มีช่องว่าง (Gap) ขนาดเท่าใด มีบริเวณใดเกิดการค้ำยัน เมื่อนำมาประกอบเข้าด้วยกัน ซึ่งจะช่วยให้การปรับประกอบแม่พิมพ์ทำได้แม่นยำและมีความรวดเร็วขึ้น

ตรวจสอบขนาดเผื่อของเนื้อวัสดุ (Allowance Check) ให้สัมพันธ์กับกระบวนการตัดเฉือนที่ต้องการ ไม่น้อยเกินไปจนเกิดความบกพร่องไม่สมบูรณ์ เช่น เนื้อแหว่ง โพรงอากาศ ขนาดเผื่อไม่มากเกินไปจนต้องเสียเวลาและต้นทุนในการผลิตที่สูงขึ้น

ตรวจการสึกหรอของแม่พิมพ์และระบุตำแหน่งบนชิ้นงาน เมื่อตรวจวัดด้วยเครื่องสแกน 3 มิติ (3D Scanner)

และเปรียบเทียบกับข้อมูลที่ถูกต้องใน CAD แล้วจะทำให้ทราบบริเวณที่เกิดการสึกหรอและขนาดที่ผิดพลาดไปจากจุดอ้างอิงที่กำหนดไว้ก่อนหน้า ทำให้สามารถแก้ไขได้อย่างรวดเร็วและถูกต้อง

2. การออกแบบและพัฒนาผลิตภัณฑ์

เครื่องสแกน 3 มิติ สามารถตรวจวัดชิ้นงานต้นแบบได้อย่างแม่นยำและรวดเร็ว ทำให้ผู้ออกแบบและพัฒนาผลิตภัณฑ์ทำงานได้รวดเร็วและยังได้คุณภาพงานที่ดีอีกด้วย อีกทั้งในปัจจุบัน ZEISS Inspect Pro สามารถทำงานแบบ Scan to CAD ได้โดยตรงโดยไม่ต้องใช้ซอฟต์แวร์เสริม ทำให้การตรวจวัดและงาน Reverse engineering ง่ายและสะดวกขึ้นเป็นอย่างมาก

3. การตรวจสอบคุณภาพ

ช่วยให้การตรวจสอบมีความแม่นยำและสร้างความเชื่อถือให้กับผลิตภัณฑ์ได้เป็นอย่างดี ทั้งด้านการตรวจสอบขนาดพื้นฐานโดยทั่วไปหรืองานตรวจสอบดังนี้

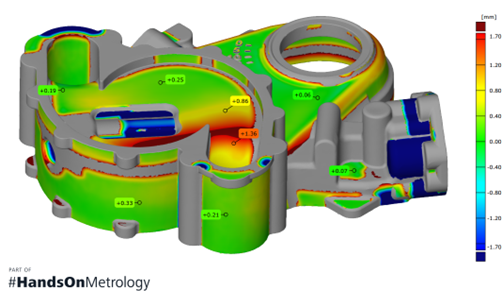

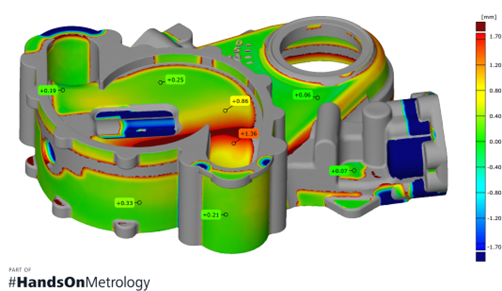

- การเปรียบเทียบชิ้นงานที่วัดได้กับ CAD (Deviation to CAD) โดยแสดงด้วยเฉดสีที่จะบ่งบอกถึงค่าความคลาดเคลื่อนจากต้นแบบ เปรียบเทียบรายละเอียดได้ทั่วทั้งชิ้นงาน

- ใช้ตรวจสอบความหนา การวัดและรายงานผลจะนำเสนอเฉพาะเรื่องความหนาเท่านั้น จากรูปตัวอย่างพื้นสีน้ำเงินเข้มจะมีผนังบางกว่าค่ามาตรฐาน -1.7 มม. ทำให้เห็นความผิดปกติได้ง่าย

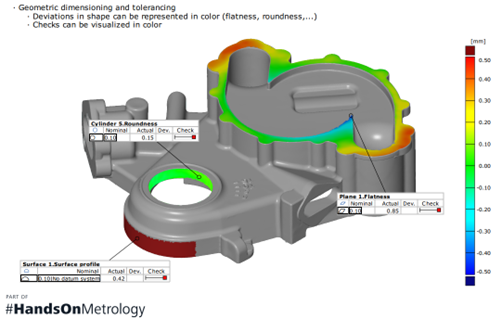

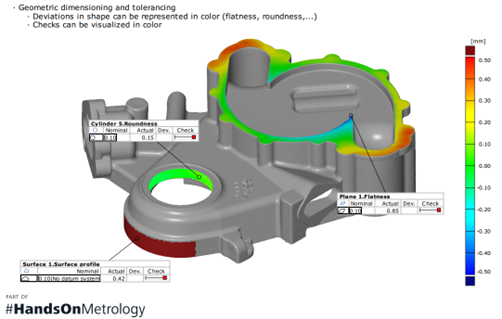

- การตรวจสอบ GD&T : ZEISS Inspect Pro สามารถแสดงรายงานผล ตามมาตรฐาน GD&T ทุกรายการ ทั้งในรูปแบบตัวเลขและความแตกต่างของสี ตามตัวอย่างรายงานแสดงผลค่า Cylindrical, Roundness, Profile of Surface, และ Flatness

เทคโนโลยีที่สำคัญของเครื่องสแกน 3 มิติในงานอุตสาหกรรม ซึ่งต้องการความแม่นยำสูง ทนทานและใช้งานได้หลากหลาย มี 2 รูปแบบดังนี้

- เครื่องสแกน 3 มิติ (3D Scanner)แบบเลเซอร์ จะใช้ลำแสงเลเซอร์ยิงลงไปบนชิ้นงานแล้วสะท้อนกลับเป็น Cloud Point และแปลงเป็น Mesh ปัจจุบันได้รับความนิยมเป็นอย่างมาก เนื่องจากมีขนาดเล็ก เบา เคลื่อนย้ายไปตามพื้นที่ต่างๆได้ง่าย ZEISS ได้พัฒนาเครื่องสแกน 3 มิติ (3D Scanner) HandsOnMetrology แบบพกพาในโมเดล T-Scan Hawk 2 ที่มีจุดเด่นในเรื่อง

- ขนาดเล็ก น้ำหนักเบา พกพาง่าย สามารถนำไปใช้งานในพื้นที่ปฏิบัติงานได้

- สแกนได้รวดเร็วและให้รายละเอียดสูง สามารถใช้เลเซอร์สีฟ้าแบบหลายเส้น (Multiple Blue Laser Crosses) ปรับความละเอียดในระหว่างการสแกนในงานเดียวกันได้ ทำให้วัดงานได้เร็วและวัดงานละเอียดผสมอยู่ในงานชิ้นเดียวกันได้

- Workflow Assistance ช่วยให้การใช้งานสะดวก สามารถควบคุมการทำงานที่มือจับโดยตรง ไม่ต้องควบคุมผ่านเครื่องคอมพิวเตอร์

- วัดงานขนาดใหญ่ด้วย Satellite Mode สแกนงานได้ขนาดใหญ่ถึง 4 เมตร โดยไม่จำเป็นต้องมี Photogrammetry และ Marker และยังคงความแม่นยำสูงถึง 0.02 mm + 0.015 mm/m

- โหมด Dark and Shiny Surfaces สำหรับงานผิวสีดำและผิวมันเงาโดยเฉพาะ ทำให้ทำงานกับพื้นผิวและวัสดุหลายรูปแบบ

2. เครื่องสแกน 3 มิติ (3D Scanner) แบบแสงสีฟ้า (Blue Light) จะฉายแสงสีฟ้าเป็นเส้นริ้ว (Fringe projection) ที่ขนาดแตกต่างกันด้วยความเร็วสูงไปบนชิ้นงาน โดยใช้กล้องคุณภาพสูงทางซ้ายและขวาของเครื่องเก็บภาพ แล้วนำมาสร้างเป็น Cloud Point และแปลงเป็น Mesh ต่อไป

จากข้อมูลที่กล่าวมาจะเห็นได้ว่าเครื่องสแกน 3 มิติ (3D Scanner) สามารถนำไปใช้งานได้หลากหลายรูปแบบในกระบวนการหล่อ และยังนำไปใช้ประโยชน์ในงานผลิตอื่นได้อีกด้วย ทั้งการออกแบบผลิตภัณฑ์ การผลิตแม่พิมพ์ การวิเคราะห์การใช้งานหรือซ่อมชิ้นส่วนต่างๆ การตรวจสอบปริมาณเนื้องานก่อนนำไปขึ้นรูปด้วยการกัดและการประกอบชิ้นส่วนต่างๆ เข้าด้วยกัน

Article by: MEGA Tech & Factory Max (Thailand) Co., Ltd. << Click Here