Article by: Carl Zeiss PTE LTD. & MEGA Tech

การตรวจสอบคุณภาพของชิ้นงานเป็นกระบวนการที่สำคัญในกระบวนการผลิต ที่ไม่สามารถหลีกเลี่ยงได้ ดังนั้นการใช้เครื่องมือที่มีคุณภาพจึงจำเป็นอย่างยิ่งในกระบวนการนี้ ในคอลัมน์นี้ ทาง MEGA Tech นำเสนอ ZEISS CONTURA เครื่องมืดวัดสามมิติ CMM ที่มีเทคโนโลยีเซนเซอร์ ZEISS Mass Technology ที่สามารถทำงานด้วยความแม่นยำที่สูงและรวดเร็ว

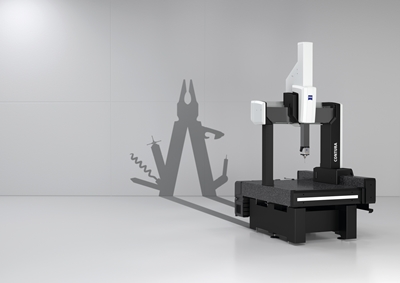

“เตรียมพร้อมรับทุกความท้าทาย – วันนี้และในอนาคต : ZEISS CONTURA”

Versatility

เครื่องมือวัดสามมิติ CMM : ZEISS CONTURA เน้นความอเนกประสงค์และง่ายต่อการปรับเปลี่ยนตามความต้องการ ซึ่งรุ่นนี้มีเทคโนโลยีระบบเซ็นเซอร์ที่ใช้งานได้หลากหลาย ทำให้สามารถปรับเปลี่ยนเซ็นเซอร์ที่เหมาะกับการใช้งานได้ง่ายและรวดเร็ว

ด้วย เครื่องมือวัดสามมิติ CMM ZEISS CONTURA คุณสามารถเตรียมพร้อมสำหรับภารกิจการวัดในอนาคตที่ไม่แน่นอน คุณสามารถปรับตามความต้องการที่เปลี่ยนไปของลูกค้าได้อย่างไร้กังวล

Opticals Sensors

เครื่องมือวัดสามมิติ CMM ZEISS CONTURA รวมการวัดแบบสัมผัสและการวัดแบบใช้แสงไว้ด้วยกันในอุปกรณ์เดียว ตั้งแต่งานวัดภาพ 2 มิติไปจนถึงเซ็นเซอร์แสงสีขาวและแบบใช้เลเซอร์วัดชิ้นงาน ZEISS CONTURA เปิดโลกเซ็นเซอร์แบบใช้แสงวัดชิ้นงาน

Rotary Table

โต๊ะหมุนจับยึดรุ่นใหม่นี้สามารถติดตั้งเมื่อต้องการใช้งานและสามารถปรับระยะที่ต้องการวัด สามารถย้ายออกนอกช่วงระยะวัดอีกครั้งเมื่อต้องการวัดงานในแบบปกติ ตัวเลือกนี้ทำให้สามารถวัดงานได้เพิ่มเป็นสี่แกน

ProMax E

ProMax E ZEISS ระบบเปลี่ยนโพรบแบบอัตโนมัติเพื่อรับประกันการวัดที่เสร็จสมบูรณ์ระหว่างกระบวนการเปลี่ยน โดยเคลื่อนเข้าช่วงระยะวัดแบบอัตโนมัติและแทนที่ระบบโพรบอย่างปลอดภัยและถูกต้องแม่นยำ

Ergonomic

เครื่องมือวัดสามมิติ CMM ZEISS CONTURA เหมาะกับห้องวัดขนาดเล็กที่ต้องใช้อุปกรณ์วัดที่ปรับตามพื้นที่ CMM ไม่เพียงมีความสูงและความกว้างที่เหมาะสม ยังมีคุณสมบัติพิเศษตามหลักการยศาสตร์ ทำให้ผู้ใช้งานทำงานได้อย่างสะดวกสบายและปลอดภัย

Future-Proof

เครื่องมือวัดสามมิติ CMM ZEISS CONTURA พร้อมสำหรับ Industry 4.0 บริการดิจิทัลของ ZEISS Smart Services ทำให้สามารถตรวจสอบการทำงานของอุปกรณ์ได้ทุกที่ตามเวลาจริง

Performance

ZEISS CONTURA ช่วยลดเวลาการวัดให้เหลือน้อยที่สุดโดยยังคงระดับความถูกต้องที่น่าเชื่อถือได้ ซึ่งรับประกันด้วยฟังก์ชั่นต่างๆ เช่น ระบบการวัด ZEISS VAST navigator หรือ ZEISS VAST performance ที่ใช้ร่วมกับหัวโพรบ ZEISS VAST