Article by: ZEISS & MEGA Tech Magazine

“ด้วย เครื่องมือวัด ZEISS T-SCAN เรายังสามารถสแกนชิ้นส่วนขนาดใหญ่และหนักได้จากทั้งสี่ด้านและจากด้านบน โดยไม่ต้องย้ายชิ้นส่วนไปยังห้องแล็ปแต่อย่างใด”

เมื่อ A Robot Grasps a Cylinder Block ที่มีน้ำหนัก 50 กิโลกรัม และนำไปยังแท่นเครื่องตัดด้วยใบเลื่อยหรือเครื่องกัด จำเป็นต้องหลีกเลี่ยงการเคลื่อนที่จากการสั่นหรือการเลื่อน แต่การเบี่ยงเบนจากข้อมูลการผลิตอาจจะทำให้เรื่องยากสำหรับหุ่นยนต์ในการจับชิ้นส่วนดังกล่าว

August Mössner GmbH & Co. KG ซึ่งเป็นบริษัทที่มีความเชี่ยวชาญการผลิตเครื่องจักรพิเศษสำหรับอุตสาหกรรมการหล่อเหล็กและอลูมิเนียม ซึ่งมาพร้อมกับการผลิตเลื่อยที่ใช้งานสำหรับวัตถุที่มีความหลากหลาย เช่นเดียวกับอุปกรณ์สำหรับการรื้อถอนสถานีไฟฟ้าพลังงานนิวเคลียร์ ซึ่งได้พบว่าระบบสำหรับการนำมาแก้ไขปัญหาเรื่องนี้ เช่นเดียวกับตัวหุ่นยนต์ที่ปรับแต่งได้ตามต้องการสำหรับหุ่นยนต์ที่ผลิตขึ้นมาโดยการสนับสนุนของเครื่องมือวัด ZEISS T-SCAN ทำให้การโปรแกรมการทำงานอุปกรณ์นั้นสามารถทำได้ดีที่สุดโดยใช้การสแกนด้วยเลเซอร์ที่มีความยืดหยุ่นสูง

การเบี่ยงเบนจากค่าที่กำหนดในระดับหลายมิลลิเมตร

ทีมงานของ คริสเตียน Kunz มีบทบาทที่สำคัญเมื่อค่าที่กำหนดมีการเบี่ยงเบนจากที่ตั้งไว้ พนักงาน 20 คนจากฝ่ายปฏิบัติการหุ่นยนต์ของแผนกวิจัยและพัฒนา เป็นผู้รับผิดชอบสำหรับการวางแผนการทำงานที่เที่ยงตรง ปลอดภัย และมีประสิทธิภาพสำหรับสายการผลิตดังกล่าว

แต่ไม่ว่าจะทำอะไรก็ตาม เราต้องทำอย่างรอบคอบ และคิดให้รอบด้าน และรายละเอียดเป็นเรื่องที่สำคัญ โดยหนึ่งในรายละเอียดเหล่านี้คือ ชิ้นส่วนที่มีส่วนโค้ง ตามตัวอย่างที่กล่าวมาคือ A Robot Grasps a Cylinder Block ซึ่งจะมีขนาดเล็กมากประมาณเท่ากับลูกยางสำหรับกีฬาฮอกกี้ แต่ต้องสามารถจับชิ้นส่วนงานหล่อได้อย่างแม่นยำ และจับให้อยู่ในตำแหน่งระหว่างกระบวนการผลิตซึ่งต้องต้านกับแรงที่เกิดขึ้น เพื่อจุดประสงค์ในการนี้ ชิ้นส่วนที่มีส่วนโค้งจะมีส่วนเว้าเพื่อให้เข้ากันพอดีกับส่วนนูนออกมาของชิ้นงานหล่อ แต่อย่างไรก็ตามก็ไม่ใช่กรณีในตอนเริ่มแรก

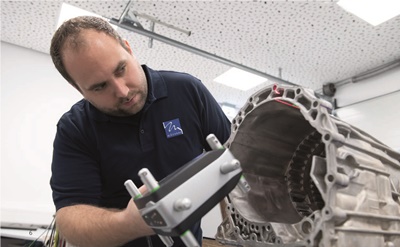

Kunz จับชิ้นส่วนที่มีส่วนโค้งซึ่งเป็นตัวเรือนกระปุกเกียร์ที่หล่อขึ้นมาอย่างหยาบ ในจุดที่ซึ่งจะใช้หุ่นยนต์เพื่อหยิบชิ้นส่วนประกอบขึ้นมา แต่ไม่ว่าวิศวกรแมคคาทรอนิกส์จะพยายามหมุนและเอียงแบบใดก็ตามเพื่อให้เข้ากันได้พอดี แต่ในที่สุดชิ้นส่วนก็ยังไม่สามารถเข้ากันพอดีได้ “เมื่อผู้ประกอบรถยนต์ส่งชิ้นงานหล่อมาให้เรา บ่อยครั้งเราจะพบว่า ชิ้นงานเหล่านี้มีค่าเบี่ยงเบนจากค่าที่ออกแบบไว้ในระดับสองสามมิลลิเมตร” Kunz อธิบาย ชิ้นส่วนเหล่านี้เป็นชิ้นส่วนที่เราเรียกว่า ชิ้นส่วนเริ่มแรกสำหรับเครื่องยนต์รุ่นใหม่

ค่าความเผื่อยินยอมยังคงมีขนาดใหญ่ เมื่อมีการเริ่มต้นการผลิตแบบตามลำดับขึ้น และไม่ได้แสดงให้เห็นในแบบจำลอง CAD ของชิ้นงานหล่อ Kunz และทีมของเขาพบวิธีการแก้ปัญหาว่าเครื่องมือวัด ZEISS T-SCAN เป็นส่วนสำคัญในการแก้ไขปัญหา โดยการใช้เครื่องสแกนแบบมือถือ วิศวกรได้วัดค่าส่วนโค้งผิวของชิ้นงานหล่อ ตัวอย่างเช่น เสื้อสูบเครื่องยนต์หรือตัวเรือนเกียร์ และเปรียบเทียบกับชุดข้อมูลที่สร้างขึ้นโดยข้อมูล CAD เป้าหมาย ซึ่งส่งให้โดยผู้ผลิตรถยนต์

ด้านหนึ่งคือ ข้อมูลนี้จะถูกใช้สำหรับการจัดทำเอกสารสถานะจริง และอีกด้านหนึ่งคือ การวัดค่านี้เป็นพื้นฐานสำหรับการปรับเปลี่ยนชิ้นส่วนที่มีส่วนโค้งจนถึงชิ้นงานหล่อ และสำหรับการโปรแกรมหุ่นยนต์ที่เกิดขึ้นภายหลัง ด้วยวิธีการนี้ วิศวกรสามารถที่จะมองเห็นได้ว่า จุดใดบ้างที่มีการเบี่ยงเบนและสามารถที่จะเริ่มต้นทำงานซ่อมชิ้นส่วนที่มีส่วนโค้งได้ ชิ้นส่วนที่มีส่วนโค้งจะถูกซ่อมด้วยมือ และจากนั้นจะถูกสแกน และหลังจากนั้นจะทำเป็นเอกสารและแปลงเป็นข้อมูล CAD อีกครั้งหนึ่ง