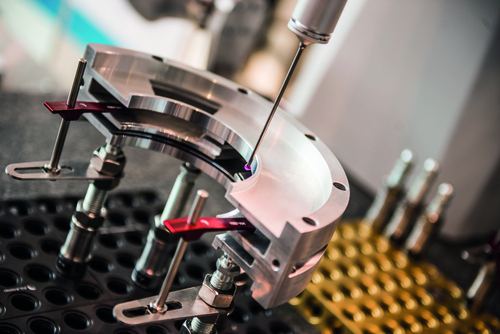

เครื่องวัดพิกัดแบบ 3 มิติ TIGO SF จาก Hexagon ออกแบบโดยเฉพาะสำหรับงานตรวจวัดใกล้กับสายการผลิตหรือในสายการผลิต

บริษัทผู้ผลิตในปัจจุบันต้องการให้ผลิตภัณฑ์มีคุณภาพสูงสุดและกระบวนการผลิตมีความประหยัดและเชื่อถือได้สูงสุด ดังนั้น เราจึงเห็นแนวโน้มความต้องการที่เพิ่มสูงขึ้นเรื่อยๆ ในการตรวจวัดชิ้นงานใกล้กับสายการผลิต

คุณภาพของผลิตภัณฑ์ขึ้นอยู่กับความแม่นยำและสม่ำเสมอของอุปกรณ์วัดและตรวจสอบเป็นสำคัญ ทำให้การเลือกเครื่องมือวัดที่เหมาะกับความต้องการกลายเป็นปัจจัยขับเคลื่อนสำคัญต่อประสิทธิภาพของกระบวนการผลิต

เครื่องวัดพิกัดแบบ 3 มิติ (Coordinate Measuring Machine หรือ CMM) รุ่น TIGO SF จาก Hexagon ให้ความเที่ยงตรงสูง ขนาดเล็ก และอเนกประสงค์ พร้อมทั้งยังออกแบบมาโดยเฉพาะสำหรับงานตรวจวัดภายในโรงงาน โดยผสมผสานการออกแบบที่แข็งแรง นวัตกรรมใหม่ทางเทคโนโลยี และความยืดหยุ่นในการใช้งาน เพื่อให้มั่นใจได้ถึงคุณภาพงานตรวจวัดที่มีความเที่ยงตรงสูง เชื่อถือได้ และมีประสิทธิภาพสำหรับงานทุกประเภท

เครื่อง CMM รุ่นนี้รองรับปริมาตรการวัดที่ 500 x 580 x 500 มม. (แกน X/Y/Z) จึงเหมาะเป็นพิเศษสำหรับงานตรวจสอบชิ้นงานขนาดเล็กและกลางทุกประเภทในทุกอุตสาหกรรม

ให้ประสิทธิภาพสูงสุดแม้ในสภาพแวดล้อมที่ไม่เอื้ออำนวย

เครื่อง CMM ของเรามาพร้อมการออกแบบที่เน้นความแข็งแกร่งและเทคโนโลยีการตรวจวัดขั้นสูง เพื่อตอบสนองความท้าทายทุกรูปแบบของสภาพแวดล้อมภายในโรงงาน ไม่ว่าจะเป็นการสั่นสะเทือน ความผันผวนของอุณหภูมิ คุณภาพอากาศ และสารปนเปื้อนต่างๆ

ตัวเครื่องมาพร้อมคุณสมบัติและความสามารถต่างๆ เช่น:

- ฝาครอบและปลอกหุ้มช่วยปกป้องโครงสร้างของเครื่องจากฝุ่นและสิ่งปนเปื้อนในอากาศ

- แกนเครื่องเคลื่อนที่โดยการสไลด์บนรางสเตนเลสสตีลตรงที่ให้ความเชื่อถือได้สูงและแบริ่งแบบแข็ง

- โต๊ะงานแกรนิตเพิ่มความมั่นคงให้โครงสร้าง

- ทนต่อการสั่นสะเทือนสูง เนื่องจากมีระบบดูดซับแรงสั่นสะเทือนแบบพาสซีฟช่วยป้องกันไม่ให้เครื่อง CMM ได้รับผลกระทบจากการสั่นสะเทือน รวมทั้งยังสามารถติดตั้งอุปกรณ์เสริมเป็นระบบดูดซับแรงสั่นสะเทือนแบบแอ็คทีฟได้เช่นกัน เพื่อป้องกันโครงเครื่องจากแรงสั่นสะเทือนและปกป้องตัวเครื่องได้ดียิ่งขึ้นสำหรับโรงงานที่มีการสั่นสะเทือนรุนแรง

- มีขาตั้งระดับการป้องกัน IP54 เป็นอุปกรณ์เสริมในกรณีที่ต้องการการปกป้องอีกระดับสำหรับคอมพิวเตอร์ PC และอุปกรณ์อิเล็กทรอนิกส์อื่นๆ ในสภาพแวดล้อมที่ไม่เอื้ออำนวย

TIGO SF รองรับช่วงอุณหภูมิทำงานมาตรฐานตั้งแต่ 15°C ถึง 30°C ทำให้สามารถใช้งานได้ในพื้นที่ผลิตที่ไม่มีระบบปรับอากาศ และยังรองรับช่วงอุณหภูมิทำงานกว้างขึ้นในรุ่น XT (Extended Temperature) ซึ่งสามารถตรวจวัดได้อย่างแม่นยำและเที่ยงตรงที่อุณหภูมิสูงสุด 40°C โดยใช้ระบบเซ็นเซอร์ความร้อนร่วมกับระบบชดเชยความร้อนทางโครงสร้างประสิทธิภาพสูงและขาตั้งเครื่องแบบมีระบบปรับอากาศ

ตรวจวัดได้รวดเร็ว แม่นยำ และยืดหยุ่น

TIGO SF รองรับหัวโพรบทั้งแบบอยู่กับที่และแบบปรับตำแหน่งได้ ทำให้รองรับการใช้งานได้หลากหลายรูปแบบ

เครื่อง CMM มาพร้อมหัวโพรบสแกน 3 มิติ HP-S-X1C แบบติดตั้งถาวร ซึ่งให้ความแม่นยำสูงและรวดเร็วสำหรับโหมดการสแกนแบบจุดต่อจุดและแบบต่อเนื่อง โดยสามารถเก็บจุดข้อมูลหลายพันจุดได้อย่างรวดเร็วโดยอัตโนมัติ ทำให้สามารถประเมินคุณลักษณะทั้งหมดของชิ้นงานได้อย่างครบถ้วนและเที่ยงตรง ไม่ว่าจะเป็นรูปทรง ตำแหน่ง และขนาด

Hexagon ยังยกระดับความอเนกประสงค์และความยืดหยุ่นของระบบไปอีกขั้นด้วยออปชั่นใหม่สำหรับเครื่อง CMM ด้วยการติดตั้งหัวโพรบแบบปรับตำแหน่งอัตโนมัติ HH-A-T5° และโพรบสแกน HP-S-X1S ซึ่งออปชั่นนี้ช่วยเพิ่มความสะดวกให้กับการตรวจสอบคุณลักษณะของชิ้นงาน โดยจะปรับทิศทางตามชิ้นงานและไม่จำเป็นต้องใช้หัวโพรบรูปดาวหรือโต๊ะงานหมุน นอกจากนั้นแล้ว HP-S-X1S ยังใช้ข้อต่อแบบคิเนเมติก ช่วยให้สามารถเปลี่ยนโพรบได้แบบอัตโนมัติโดยใช้แร็คเปลี่ยนโพรบ

การรวมระบบและระบบออโตเมชั่นในโรงงาน

การเก็บรวบรวมข้อมูลสำหรับตรวจสอบคุณภาพเพียงอย่างเดียวนั้นไม่เพียงพอ สิ่งสำคัญคือจะต้องสามารถนำข้อมูลมาตรวิทยาเหล่านี้ไปใช้กับการผลิตได้ทันทีและตามเวลาจริง บริษัทผู้ผลิตต่างมองหาวิธีที่จะรวมระบบ CMM เข้ากับระบบเชื่อมต่ออัจฉริยะเพื่อยกระดับคุณภาพผลิตภัณฑ์และประสิทธิภาพของกระบวนการผลิต เพื่อช่วยให้ประหยัดเวลาและต้นทุนได้ในที่สุด

TIGO SF ได้รับการออกแบบมาให้พร้อมทันทีสำหรับการรวมระบบโดยตรงเข้ากับกระบวนการผลิต ทั้งแบบวางเครื่องใกล้กับเครื่องจักรและภายในสถานีตรวจสอบอัตโนมัติ โดยมีความสามารถต่างๆ ที่ช่วยให้ผู้ผลิตสามารถรวมระบบของเครื่องเข้ากับสายการผลิตและเปลี่ยนงานตรวจสอบให้เป็นระบบอัตโนมัติได้อย่างสะดวก

เครื่อง CMM ของเรามาพร้อมชุดอุปกรณ์อินพุต-เอาต์พุตที่ทันสมัย ซึ่งช่วยให้สามารถรับส่งและแลกเปลี่ยนสัญญาณและข้อมูลต่างๆ ภายในสายการผลิต โดยสามารถใช้ข้อมูลจากเครื่อง CMM เพื่อชดเชยค่าการทำงานของเครื่องจักรในการผลิตได้แบบอัตโนมัติ หรือสามารถที่จะใช้ข้อมูลเกี่ยวกับสิ่งแวดล้อมเพื่อลดปริมาณของเสีย รวมทั้งยังรองรับการทำงานร่วมกับหุ่นยนต์และระบบบรรจุชิ้นงานอัตโนมัติ เพื่อให้กระบวนการผลิตมีประสิทธิภาพมากยิ่งขึ้น

ความสามารถด้านซอฟต์แวร์

เครื่อง CMM รุ่นนี้มาพร้อมซอฟต์แวร์ตรวจวัดประสิทธิภาพสูง PC-DMIS ซึ่งช่วยให้ผู้ปฏิบัติงานสามารถสร้างและดำเนินการขั้นตอนการตรวจวัดได้อย่างสะดวก รวมทั้งสามารถตัดสินใจปรับแก้ได้โดยใช้ข้อมูลที่ได้รับ และยังมีอินเตอร์เฟสควบคุม Inspect ซึ่งใช้งานง่าย สามารถทำขั้นตอนการตรวจวัดกับชิ้นงานทุกประเภท ตั้งแต่ชิ้นงานง่ายๆ ไปจนถึงชิ้นงานที่มีรูปทรงซับซ้อน โดยไม่ต้องมีความเชี่ยวชาญพิเศษใดๆ

นอกจากนั้นแล้ว ยังมีเทคโนโลยีซอฟต์แวร์ทางสถิติอย่าง PULSE และ Q-DAS (อุปกรณ์เสริม) ที่จะช่วยเพิ่มคุณภาพและลดปริมาณของเสียผ่านทางระบบตรวจสอบสภาพแวดล้อมและระบบวิเคราะห์ข้อมูลสถิติ

ระบบตรวจสอบสภาพแวดล้อม PULSE รองรับขั้นตอนการควบคุมคุณภาพโดยใช้ชุดเซ็นเซอร์เพื่อบันทึกปัจจัยต่างๆ ที่เกี่ยวข้องกับเครื่อง CMM ซึ่งอาจส่งผลต่อคุณภาพของข้อมูลที่วัดได้ ไม่ว่าจะเป็นการสั่นสะเทือน อุณหภูมิและความชื้น ความดันอากาศ รวมทั้งยังสามารถแจ้งเตือนให้ผู้ควบคุมเครื่องทราบในกรณีที่เครื่องหยุดทำงานโดยไม่คาดคิด ทำให้เห็นภาพรวมของขั้นตอนการตรวจสอบอย่างชัดเจน พร้อมทั้งยังสามารถให้คำแนะนำเพื่อให้กระบวนการตรวจวัดมีประสิทธิภาพสูงสุดไปจนถึงข้อมูลวิธีแก้ปัญหาที่สามารถนำไปดำเนินการได้ทันที

ชุดซอฟต์แวร์ควบคุมกระบวนการทางสถิติ Q-DAS เป็นอีกทางเลือกหนึ่งในกรณีที่ต้องการระบบตรวจสอบเครื่องจักรและกระบวนการทำงานที่มีประสิทธิภาพสูงขึ้นอีกขั้น ชุดซอฟต์แวร์นี้มีเครื่องมือวิเคราะห์ประสิทธิภาพสูงเพื่อควบคุมคุณภาพของการผลิต ข้อมูลที่เก็บรวบรวมโดย TIGO SF สามารถนำมาใช้กับระบบคำนวณอัตโนมัติของเครื่องจักร เพื่อปรับแก้ค่าต่างๆ และลดจำนวนชิ้นงานเสีย

ข้อมูลเชิงลึกจากซอฟต์แวร์เหล่านี้เป็นข้อมูลสำคัญอย่างยิ่งสำหรับสภาพแวดล้อมการผลิตที่มีความผันผวนสูง โดยจะช่วยให้ได้รับข้อมูลที่ถูกต้องและเชื่อถือได้และสามารถแก้ปัญหาที่เกิดขึ้นได้อย่างทันท่วงที ข้อดีสำคัญอีกอย่างหนึ่งคือการลดจำนวนชิ้นงานที่ถูกปฏิเสธให้น้อยลงด้วยฟังก์ชั่นการทำงานและการแจ้งเตือนที่รองรับการทำงานแบบตามเวลาจริง

ระบบบรรจุชิ้นงานอัตโนมัติ: แค่บรรจุชิ้นงาน กำหนดตารางงาน แล้วไปพักได้เลย

TIGO SF ออกแบบให้สามารถเข้าถึงได้จากสามด้าน ทำให้จัดการกับชิ้นงานที่จะทำการวัดได้สะดวกเป็นพิเศษ จึงเหมาะสำหรับการใช้งานร่วมกับหุ่นยนต์เคลื่อนย้ายชิ้นงานและการรวมระบบเข้ากับสถานีผลิตอัตโนมัติและสายการผลิต

เครื่อง CMM รุ่นนี้รองรับการทำงานร่วมกับ TEMPO ซึ่งเป็นระบบบรรจุชิ้นงานอัตโนมัติจาก Hexagon โดย TEMPO จะทำหน้าที่บรรจุชิ้นงาน จัดคิว และนำชิ้นงานออกจากเครื่องโดยอัตโนมัติ ทำให้สามารถทำขั้นตอนตรวจวัดได้อย่างต่อเนื่องหลายชั่วโมงโดยไม่ต้องใช้คนคอยควบคุมดูแล หรือทำงานแบบอัตโนมัติตลอดทั้งกะ หรือแม้แต่กับการผลิตแบบไม่ใช้คนควบคุมเลย ผู้ควบคุมเครื่องจึงมีเวลาว่างสำหรับทำงานอื่นๆ ซึ่งจำเป็นมากกว่า

ระบบนี้ช่วยเพิ่มประสิทธิภาพการผลิตได้อย่างมากและยังช่วยเพิ่มประสิทธิผลโดยรวม (Overall Equipment Effectiveness หรือ OEE) ของเครื่อง CMM ได้อีกทางหนึ่ง

สรุป

เป้าหมายของผู้ผลิตคือขั้นตอนการผลิตที่ต่อเนื่องราบรื่น ตั้งแต่การกัด การเจาะ การทำเกลียว และการเจียจนกระทั่งการตรวจสอบขั้นสุดท้าย และการจะก้าวนำหน้าคู่แข่งได้เสมอนั้น ผู้ผลิตจำเป็นต้องมีเทคโนโลยีที่สามารถปรับปรุงคุณภาพและประสิทธิภาพของกระบวนการทำงานที่สำคัญเหล่านี้ รวมไปถึงกระบวนการอื่นๆ ได้ TIGO SF คือเครื่อง CMM ที่มีทั้งความแม่นยำ อเนกประสงค์ และเชื่อถือได้ ผสมผสานเทคโนโลยีการตรวจวัดขั้นสูงต่างๆ เข้าด้วยกันอย่างครบถ้วน และเป็นหนึ่งในอุปกรณ์มาตรวิทยาที่ให้ประสิทธิภาพสูงสุดสำหรับกระบวนการผลิตอัจฉริยะภายในโรงงาน

Article by: https://hexagon.com/