เทคโนโลยีใหม่เพื่อการวัดตรวจสอบการันตีการใช้งานจาก Carl Zeiss GOM Metrology ผู้บริโภคและผู้ผลิตจะมั่นใจได้อย่างไรว่าในขั้นตอนตรวจสอบชิ้นงาน ในธุรกิจรถยนต์ไฟฟ้าให้ได้คุณภาพ ถูกต้อง แม่นยำ ในยุคจากเครื่องยนต์สันดาปเป็นระบบไฟฟ้า บทความ Measurement เครื่องมือวัด ฉบับนี้ MEGA Tech มีคำตอบให้

ตลาดยานยนต์ EV เติบโตอย่างมากในช่วง 10 ปีหลัง ปัจจัยหลักจากการรับรู้ถึงประโยชน์ของรถยนต์ไฟฟ้า EV ทั้งในแง่ความประหยัดค่าเชื้อเพลิง ความเป็นมิตรต่อสิ่งแวดล้อม ทำให้คนนิยมใช้อย่างแพร่หลายโดยเฉพาะในยุโรป รวมถึงจีนที่ปัจจุบันเป็นตลาดรถยนต์ไฟฟ้า EV ที่ใหญ่ที่สุดของโลกไปแล้ว เช่นเดียวกับในไทยที่ยอดขายรถยนต์ไฟฟ้า EV เพิ่มสูงขึ้นอย่างต่อเนื่อง

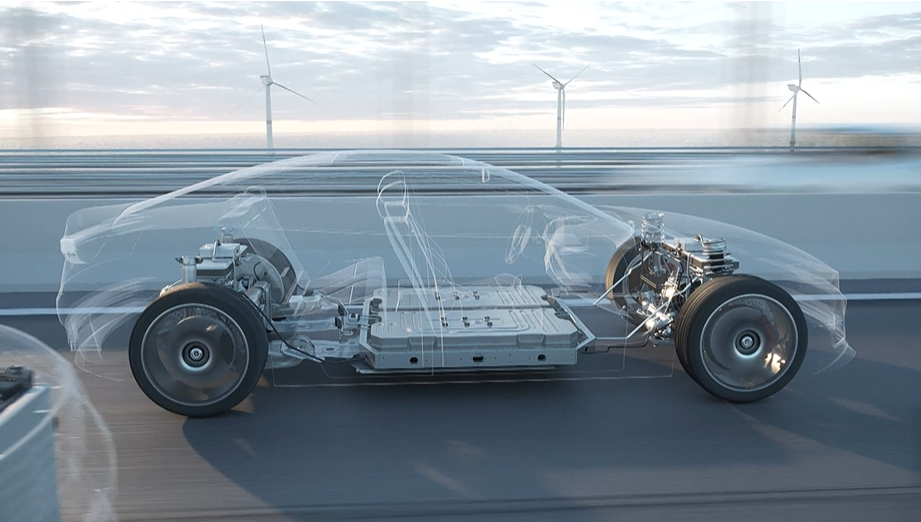

ยกตัวอย่างเช่น ในปี 2021 เป็นครั้งแรกที่รถยนต์ไฟฟ้าเป็นรถยนต์ที่ขายดีที่สุดในยุโรป นั่นคือ Tesla Model 3 และในปี 2023 ยอดจองของ Tesla ในไทยพุ่งทะลุ 5,000 คัน สิ่งที่ Tesla ทำคือการที่มองเห็นตลาดและคว้าโอกาส พร้อมกับสร้างความเชื่อมั่นในคุณภาพของผลิตภัณฑ์ที่ผ่านการตรวจสอบมาอย่างแม่นยำ โดยเฉพาะอย่างยิ่ง ถาดรองสำหรับบรรจุแบตเตอรี่ ในรถยนต์ไฟฟ้า (EV) ซึ่งถือว่าเป็นหัวใจสำคัญของรถยนต์ไฟฟ้า

สิ่งที่ผู้ผลิตและลูกค้านั้นมีคาดหวังที่สูงขึ้นโดยเฉพาะเรื่องของการชาร์จแบตเตอรี่ที่สามารถอยู่ได้นานและปลอดภัย การสร้างแบตเตอรี่ที่มีความน่าเชื่อถือพร้อมอายุการใช้งานที่ยาวนาน มาตรฐานในการผลิตจึงเป็นเรื่องที่ต้องให้ความสำคัญสูงสุด เพราะ “แบตเตอรี่เป็นหัวใจสำคัญของรถยนต์ไฟฟ้า” การรับประกันคุณภาพสำหรับแบตเตอรี่เป็นกระบวนการที่ซับซ้อน เครื่องมือที่จะเข้ามาช่วยในการตรวจวัดจึงต้องมีความละเอียดและแม่นยำ

“สิ่งที่ผู้ผลิตและผู้ประกอบการต้องคำนึงถึง คือ การรับมือและปรับตัวให้ทันต่อความต้องการของลูกค้า” ในยุคที่เทคโนโลยีมีบทบาทต่อการใช้ชีวิต ผู้บริโภคสามารถรับรู้และเข้าถึงขั้นตอนการผลิต เพื่อสร้างความเชื่อมั่นว่ารถยนต์ไฟฟ้าก่อนจะออกมาเป็นผลิตภัณฑ์สู่ตลาดนั้นต้องผ่านการวิจัยและพัฒนาหลายขั้นตอน

โดยชิ้นส่วนที่จะยกตัวอย่างในการตรวจสอบครั้งนี้ คือ ถาดรองสำหรับบรรจุแบตเตอรี่ ในรถยนต์ไฟฟ้า (EV) เป็นชิ้นส่วนที่น่าจับตามอง เพราะตลาดรถยนต์ไฟฟ้ากำลังเติบโตอย่างรวดเร็วในระดับโลก และเป็นเทรนด์ที่กลุ่มเป้าหมายให้ความสนใจ ในฐานะผู้ผลิตจะสร้างความเชื่อมั่นให้กับผู้บริโภคได้อย่างไรในเรื่องของความปลอดภัย ด้วยเทคโนโลยี 3 มิติ ATOS Scanbox

เหตุใดคุณภาพของโซลูชันการตรวจสอบ 3 มิติ จึงมีความสำคัญ

● พัฒนาผลิตภัณฑ์ออกสู่ตลาดได้เร็วขึ้นกว่าเดิม

● สร้างกำไรให้กับธุรกิจ

● เพิ่มข้อได้เปรียบในการแข่งขันที่ดี

● แก้ปัญหาคุณภาพในทันที หาวิธีแก้ไขที่เหมาะสมที่สุดอย่างรวดเร็ว

● กำจัดกระบวนการที่ซ้ำกันโดยไม่จำเป็น

● ทำงานไวขึ้น แต่ยังทรงประสิทธิภาพ

● เซฟต้นทุน ช่วยลดปัญหาที่เกิดขึ้นในการทำงาน

● ปรับปรุงคุณภาพผลิตภัณฑ์

ในอุตสาหกรรม 4.0 จะช่วยทำให้เครื่องจักรอัจฉริยะฉลาดขึ้น การผลิตมีประสิทธิภาพมากขึ้น กระบวนการที่สิ้นเปลืองน้อยลง สายการผลิตมีความยืดหยุ่นและผลผลิตสูงขึ้น การเลือกเทคโนโลยีที่ถูกต้องเป็นสิ่งสำคัญ โซลูชันการตรวจวัดแบบอัตโนมัติ โดย Carl Zeiss GOM Metrology สามารถช่วยให้ผู้ผลิตและผู้ประกอบการสามารถรับข้อมูลได้ทันทีและใช้งานได้จริง

เครื่องวัด 3D แบบออปติคอล ATOS ScanBox มาพร้อมกับซอฟต์แวร์ GOM Inspect Pro สแกนชิ้นงานโดยอัตโนมัติ สามารถสแกนพร้อมกับการเก็บข้อมูล ทั้งถาดใส่แบตเตอรี่, ชุดแบตเตอรี่, ตรวจสอบความเรียบของช่องใส่แบตเตอรี่ และตำแหน่งของรูเชื่อมต่อ โดยใช้เวลาเพียงไม่กี่นาที

ผู้ผลิตและผู้ตรวจสอบงานสามารถประเมินลักษณะการตรวจสอบที่เกี่ยวข้องกับกระบวนการเป็นแนวโน้มทางสถิติ เพื่อระบุการเปลี่ยนแปลงความกว้างของช่องว่างที่เกิดจากการเสียรูปทางความร้อนของโมดูลแบตเตอรี่

นอกจากนี้ยังสามารถจำลองแสดงการประกอบของโมเดลทั้งหมด และการเดินสายในตัวเครื่องเพื่อคาดการณ์คุณภาพของกระบวนการประกอบ การวิเคราะห์ครอบคลุมขั้นตอนสำคัญทั้งหมดในการผลิตถาดแบตเตอรี่ ตั้งแต่การอัดขึ้นรูปอะลูมิเนียมไปจนถึงการหล่อ การเชื่อม ไปจนถึงกระบวนการกัด การเจาะ และการตอกหมุด

ซอฟต์แวร์ของเครื่องวัด 3 มิติ ใช้ข้อมูล 3D CAD ของส่วนประกอบสำคัญในการโปรแกรม ATOS Scanbox เพื่อสแกนทุกตำแหน่งชิ้นงาน และการเคลื่อนที่ของหุ่นยนต์แบบอัตโนมัติอย่างอัจริยะโดยไม่ต้องใช้คน รวมไปถึงเทคโนโลยีการวัดนั้นสามารถตรวจสอบย้อนกลับได้ และเป็นไปตามข้อกำหนด ISO 10360

ATOS ScanBox บันทึกรูปทรงเรขาคณิตตามหลักงานเขียนแบบวิศวกรรมทั้งหมด มั่นใจได้เลยว่าการทำงานสแกนนั้นจะเกิดแสงรบกวนที่น้อยมาก เพราะ ATOS Scanbox มี Blue Light Technology ที่พร้อมรับมือพื้นผิวที่มืดหรือมันเงา

Article by: MEGA Tech & AppliCAD Public Co., Ltd. << Click