Article by: Hexagon Metrology (Thailand) Co., Ltd. & MEGA Tech Magazine

พรีวิวผลิตภัณฑ์: AICON PartInspect L

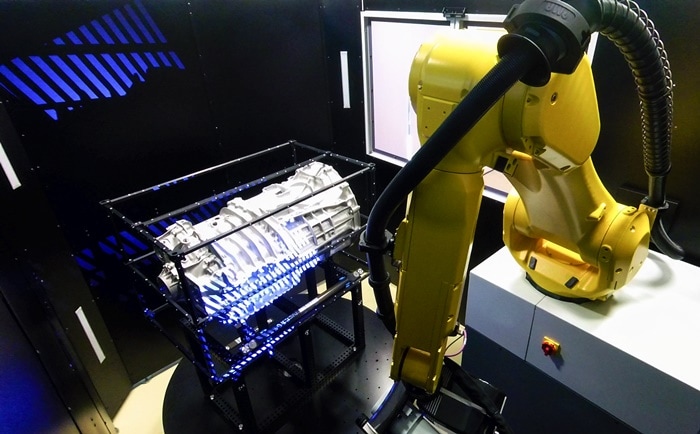

เปิดตัวทั่วโลกเดือนเมษายนนี้กับ AICON PartInspect L ใหม่ ซึ่งเป็น 3D measurement cell แบบอัตโนมัติทั้งหมด โดยอาศัยเทคโนโลยี AICON Scanner จาก Hexagon Manufacturing Intelligence กรุณาอ่านต่อเพื่อจะได้เห็นโฉมระบบอัตโนมัตินวัตกรรมใหม่ตัวนี้ก่อนใคร

PartInspect L นำแขนหุ่นยนต์ที่ทรงพลังและยืดหยุ่นเข้ากับเทคโนโลยีวัดแสง AICON Scanner ให้อยู่ภายในรูปแบบ cell ที่ครบถ้วนในตัวเอง ระบบดังกล่าวจัดการโดย software platform ส่วนตัว ซึ่งมีแผงควบคุมแบบจอสัมผัสผนวกเข้าไว้ และออกแบบมาให้เป็น modular format ซึ่งหมายความว่า สามารถทำงานได้ทันทีหลังจากการติดตั้งเครื่องหนึ่งวัน

ด้วยเครื่อง PartInspect L การทำภาพดิจิตัลสามมิติของชิ้นส่วนขนาดใหญ่และขนาดเกินมาตรฐานก็จะกลายเป็นขั้นตอนที่ง่ายดายไปเลย เพราะข้อมูลจะมีพร้อมที่สายการผลิต และสามารถดำเนินการต่อได้โดยอาศัยความรู้เรื่องหุ่นยนต์หรือการอบรมเพียงเล็กน้อยเท่านั้น

ซอฟต์แวร์เพื่อใช้งานโดยเฉพาะ

จุดเด่นหลักของ PartInspect L ที่ทำให้กระบวนการถ่ายภาพดิจิตัลพื้นผิวและคุณสมบัติของวัตถุต่างๆ เป็นเรื่องง่ายก็คือ ซอฟต์แวร์เฉพาะด้านและโซลูชั่นควบคุม ซึ่งทำให้การวางแผนการ scan และการดำเนินการเป็นเรื่องอัตโนมัติ โดยซอฟต์แวร์ PartInspect L Offline Programming Tool จะช่วยให้การเตรียมความพร้อมเพื่อวัดชิ้นงานได้อย่างหลากหลาย ผ่านระบบ user interface ที่เรียนรู้ได้อย่างง่ายดาย

PartInspect L เทคโนโลยีวัดแสง AICON Scanner from HEXAGON

PartInspect L เทคโนโลยีวัดแสง AICON Scanner from HEXAGONซอฟต์แวร์ดังกล่าวยังรวมความสามารถในการ pose (จัดวัตถุให้เข้าที่ได้อย่างรวดเร็ว) และวางแผน path (เส้นทาง) ในขณะที่ cell กำลังทำงาน ช่วยให้ลดเวลา downtime (ที่หยุดเครื่องจักร) ในระหว่างขั้นตอนการวัดแต่ละครั้ง นอกเหนือจากความสามารถในการประมวลรายงานและเก็บข้อมูลอย่างอัตโนมัติแล้ว PartInspect L ยังเป็นโซลูชั่นสำหรับการทำภาพดิจิตัลอย่างรวดเร็ว ซึ่งอาศัยคนในการดำเนินการน้อยมาก

ซอฟต์แวร์อินเตอร์เฟซสามารถเข้าถึงและใช้ควบคุม cell จากระบบคอมพิวเตอร์ผ่านหน้าจอสัมผัสที่ผนวกเข้าด้วยกัน เพื่อให้สามารถสั่งการในระดับสายการผลิตในโรงงานได้โดยตรง (shop-floor operation) แต่ก็ยังสามารถตั้งค่าโปรแกรมแบบออฟไลน์ได้เช่นกัน โดยใช้คอมพิวเตอร์ที่ต่อเข้าไว้ใกล้กับ cell หรืออยู่ที่โต๊ะของผู้ใช้งาน

ออกแบบมาเป็นโมดูล

การออกแบบฮาร์ดแวร์แบบโมดูลซึ่งเป็นแกนหลักของระบบ ช่วยให้เกิดความยืดหยุ่นมากขึ้นและช่วยลดค่าใช้จ่ายให้แก่ผู้ใช้งาน โดยมี turntable ที่ติดอยู่บน platform และส่วนประกอบหุ่นยนต์ที่ช่วยให้การติดตั้งเป็นเรื่องง่าย หรือก็คือ แค่ plug and play (“ติดตั้งแล้วก็ใช้งานได้ทันที”) และนั่นก็หมายความว่า PartInspect L สามารถติดตั้งได้ที่สถานที่ของลูกค้าและพร้อมใช้งานหลังจากการติดตั้งเพียงหนึ่งวันเท่านั้น

แนวคิดที่สร้างเป็นโมดูลที่อยู่เบื้องหลัง AICON PartInspect L ช่วยให้ระบบสามารถประกอบกันขึ้นมาก่อนและติดตั้งค่าในโรงงานก่อนที่จะถึงมือผู้ใช้งาน สิ่งนี้จะช่วยลดภาระงานทางด้านวิศวกรรมที่ต้องใช้เวลาในระหว่างติดตั้งไปได้มากพอสมควร ซึ่งทำให้การตั้งค่า cell ณ สถานที่ทำงานของลูกค้าเป็นไปได้อย่างรวดเร็วและเรียบง่าย จึงถือเป็นโซลูชั่นสำหรับงานตรวจสอบแบบอัตโนมัติที่สมบูรณ์แบบและพร้อมใช้งานอย่างแท้จริง

เวลาที่ใช้ติดตั้ง PartInspect L ที่รวดเร็วนี้ ยังช่วยให้เกิดความยืดหยุ่นมากขึ้นในการปรับการวัดชิ้นงานประเภทต่าง ๆ และชิ้นงานขนาดต่าง ๆ จึงทำให้เป็นอุปกรณ์ที่เหมาะสมกับผู้ให้บริการและผู้ผลิตสินค้า

PartInspect L ได้รับการพัฒนามาให้ดีที่สุดเพื่อเหมาะกับการวัดชิ้นงานขนาดใหญ่และเกินขนาด เพราะมีทางเข้ากว้าง (entrance) และด้านบนเปิดไว้เพื่อส่งชิ้นส่วนต่าง ๆ ผ่าน pallet transporter รถยก หรือแม้แต่ปั้นจั่น และยังมีความสามารถด้านกำลัง load ที่เพิ่มมากขึ้นอีกด้วย ทำให้สามารถรับชิ้นส่วนที่มีน้ำหนักมากถึง 2000 กิโลกรัม

ความถูกต้องแม่นยำที่มากขึ้น

มี cell วางจำหน่ายอยู่สองรุ่น รุ่นที่หนึ่ง PartInspect L Efficient ใช้ AICON PrimScan scanner และมีการ calibrate (สอบเทียบ) แล้ว เพื่อให้สามารถทำให้การเก็บข้อมูลดิจิตัลเป็นไปอย่างรวดเร็วและง่ายดาย ในระดับความถูกต้องมาตรฐาน โดยสามารถเลือกมุมมองได้สองมุมมอง (field of view) ซึ่งลูกค้าสามารถเลือกในตอนที่ซื้อผลิตภัณฑ์ โดยขึ้นอยู่กับว่า ลูกค้าจะวัดชิ้นส่วนขนาดเล็กหรือชิ้นส่วนขนาดใหญ่เป็นหลัก

รุ่นที่สอง PartInspect L HiEnd system สร้างโดยอาศัยเทคโนโลยีขั้นสูงของ AICO์N StereoScan neo scanner เป็นโซลูชั่นที่ออกแบบมาเพื่อให้ความถูกต้องแม่นยำในการวัดขั้นสูง โดยระบบจะมีมุมมองที่ผู้ใช้งานสามารถเลือกได้สองมุมมองตามที่เปิดตัว (field of view) ทำให้เกิดความยืดหยุ่นในการวัดชิ้นส่วนขนาดใหญ่และชิ้นส่วนขนาดเล็กได้ตามต้องการ

AICON PartInspect L จะเริ่มรับคำสั่งซื้อสินค้าจากตัวแทน Hexagon ที่อยู่ใกล้คุณทั่วโลกตั้งแต่ปลายเดือนเมษายน 2562 นี้เป็นต้นไป