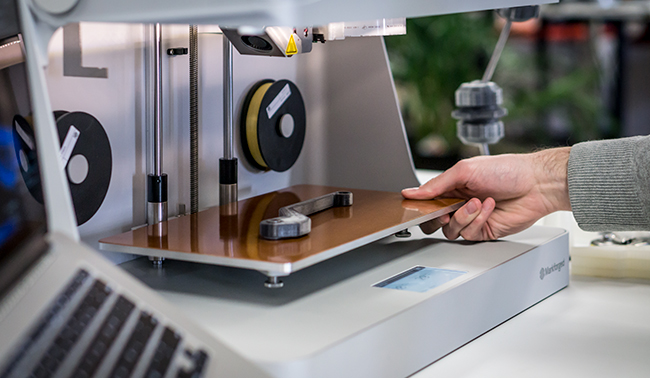

Metal Cut ฉบับนี้ ทาง MEGA Tech ยินดีนำเสนอเครื่องพิมพ์ 3มิติ จาก บริษัท เซราไทย จำกัด ที่ได้เล็งเห็นถึงความสำคัญของการเปลี่ยนแปลงอย่างรวดเร็วในปัจจุบัน ที่ส่งผลต่อการพัฒนาเทคโนโลยีในโรงงานอุตสาหกรรม โดยเครื่องพิมพ์ 3 มิติ (3D Printer) เป็นอีกหนึ่งเทคโนโลยีที่มีช่องทางในการเติบโตสูงและมีความสำคัญต่องานอุตสาหกรรมมากยิ่งขึ้น Markforged ซึ่งเป็นผู้นำด้านเครื่องพิมพ์ 3 มิติมาอย่างยาวนาน จึงเป็นเครื่องที่เราเชื่อมั่นว่าจะสามารถตอบสนองต่อความต้องการผลิตงานของลูกค้าได้อย่างมีประสิทธิภาพสูงสุด

เมื่อนึกถึงเครื่องพิมพ์ 3 มิติ (3D Printer) หลายคนยังติดภาพจำเดิม ๆ ว่าเป็นเครื่องมือที่ใช้ผลิตงานต้นแบบหรือของเล่นเท่านั้น ไม่สามารถนำไปใช้งานจริงได้ แม้จะเป็นเทคโนโลยีที่มีใช้มานานหลายสิบปี ด้วยสาเหตุหลากหลาย ตั้งแต่คุณภาพชิ้นงาน ความคงทน ความแม่นยำ วัสดุที่มีให้เลือกจำกัด แต่ด้วยเทคโนโลยีปัจจุบันที่พัฒนาอย่างรวดเร็ว ความคิดนี้จึงไม่ตรงกับความเป็นจริงอีกต่อไป เทรนด์การใช้งาน 3D Printer สำหรับชิ้นส่วนใช้งานจริง (End-use part) นี้นำโดยบริษัทอย่าง Markforged ผู้นำเทคโนโลยี 3D Printing วัสดุ Carbon Fiber และ Metal จากอเมริกา ที่มุ่งเน้นการพัฒนาโซลูชั่นที่ใช้งานได้จริงในอุตสาหกรรม ในขณะที่บริษัท 3D Printer ส่วนใหญ่โฟกัสกับตลาด Rapid Prototyping จึงถือเป็นผู้ Disrupt วงการและช่วยผลักดันให้อุตสาหกรรม 3D Printing เข้าสู่ยุคใหม่

ตลาด 3D Printer ถือเป็นอุตสาหกรรมที่มีการเติบโตในอัตราสูง ประกอบกับเหตุการณ์ช่วง 2-3 ปีที่ผ่านมา ทั้งเรื่องโรคระบาด เงินเฟ้อ สงคราม ราคาวัตถุดิบ นโยบาย Zero Covid ของจีน ยิ่งเป็นตัวเร่งให้ผู้ผลิตมองหาโซลูชั่นการผลิตชิ้นส่วนรูปแบบใหม่ แน่นอนว่า 3D Printer ยังไม่สามารถผลิตงานแทนได้ทุกอย่าง แต่เป็นวิธีการผลิตที่ตอบโจทย์หากรู้จักนำมาใช้ให้ถูกจุด นี่คือสาเหตุที่เราไม่ได้ขายแค่เครื่อง 3D Printer แต่เราพัฒนาโซลูชั่นครบวงจรที่เรียกว่า Digital Forge หรือโรงงานดิจิทัล มีทั้งเครื่องพิมพ์ วัสดุ ซอฟท์แวร์ และบริการ ให้ลูกค้าสามารถผลิตงานคุณภาพสูงที่ไหนเมื่อไหร่ก็ได้ ทำให้การทำงานยืดหยุ่น มีประสิทธิภาพ จากเดิมต้องไปง้อ Supplier ก็มาพิมพ์งานใช้เอง ลดปัญหา Supply Chain ไปเยอะ ตอนนี้กลายเป็นว่าใครไม่ลงทุนกับเทคโนโลยีใหม่ก็จะเสียเปรียบคู่แข่ง

ตามที่อธิบายข้างต้น ปัญหาที่ผู้ใช้งาน 3D Printer หลายที่เจอคือชิ้นงานไม่แข็งแรง หลายบริษัทลงทุนซื้อเครื่องพิมพ์ไปหลักล้าน พิมพ์งานออกมาใช้แล้วเปราะ หัก สุดท้ายต้องไปกัดเหล็กด้วย CNC อยู่ดี เพราะฉะนั้น Markforged จึงคิดค้นเทคโนโลยีการพิมพ์ 3D แบบใหม่ที่เรียกว่า Composite Fiber Reinforcement (CFR) หรือการพิมพ์วัสดุโพลิเมอร์เสริมวัสดุคอมโพสิตเช่น Carbon Fiber, Kevlar, Fiberglass หลักการเหมือนการหล่อคอนกรีตที่ต้องมีการเสริมเหล็กเส้นให้โครงสร้างแข็งแรง ผลลัพธ์ที่ได้คือชิ้นงานที่แข็งแกร่งเหนือ 3D Printer ทั่วไปที่พิมพ์แค่วัสดุพลาสติก ABS, PLA หลายสิบเท่า สามารถใช้งานแทนชิ้นส่วนอลูมิเนียมได้ ซึ่งตอบโจทย์การผลิตงานหลายรูปแบบ ทั้งงานต้นแบบ Jigs & Fixtures กริปเปอร์ ชิ้นส่วนอะไหล่ ชิ้นส่วนเครื่องจักรต่างๆ

Carbon Fiber เป็นวัสดุวิศวกรรมสมรรถภาพสูง มีความแข็งแกร่งเหนือโลหะ แต่น้ำหนักเบาเหมือนพลาสติก มีการใช้งานแพร่หลายในอุตสาหกรรมยานยนต์และอวกาศ เช่น บอดี้รถยนต์ไฟฟ้าของ BMW บางรุ่น รวมถึงโครงสร้างเครื่องบิน Boeing รุ่นใหม่ ที่มีส่วนประกอบเป็น Carbon Fiber มากเกือบ 50% ด้วยเหตุนี้ Markforged จึงพัฒนาเทคโนโลยีการพิมพ์ 3D โดยใช้วัสดุ Carbon Fiber ปัจจุบันมีลูกค้าผู้ใช้งานกว่า 15,000 บริษัททั่วโลก ชิ้นส่วนที่ผลิตจากเครื่องพิมพ์ของ Markforged มีการนำไปใช้งานจริงในโรงงานผลิตชิ้นส่วนยานยนต์ อิเล็กทรอนิกส์ ในสนามรบ หรือแม้กระทั่งใช้เป็นชิ้นส่วนที่ขึ้นไปในอวกาศบน International Space Station

นอกจากนี้ Markforged ยังเป็นผู้นำตลาด Metal 3D Printer ชนิดการฉีดวัสดุ (Metal FFF) ซึ่งใช้วัสดุรูปแบบเส้นลวดและนำชิ้นงานไปเข้าเตาเผา (Sintering Furnace) หลังพิมพ์เสร็จ เป็นวิธีการพิมพ์โลหะที่แตกต่างจากเครื่องพิมพ์ชนิดวัสดุผง (Powder Bed Fusion) ที่ใช้เลเซอร์หรือ Electron Beam ในการขึ้นรูปผงโลหะ ที่มีความซับซ้อนและราคาสูงมาก เมื่อเทียบกันแล้วเครื่องพิมพ์โลหะของ Markforged ออกแบบให้ใช้งานได้ง่ายที่สุด ปลอดภัยต่อผู้ใช้งาน มีความเสถียรสูง และมีราคาที่ถูกกว่ากัน 5-10 เท่า รองรับวัสดุเหล็กกล้าไร้สนิม ทองแดง อินโคเนล และเหล็กกล้าเครื่องมือหลายเกรด

ถึงแม้จะเป็นบริษัทขายเครื่อง 3D Printer แต่จริงๆ Markforged เป็นเหมือนบริษัทซอฟท์แวร์ด้วย เพราะเราเป็นเจ้าแรกที่พัฒนาระบบ Cloud Software มาใช้สั่งงาน 3D Printer ลูกค้าจะอยู่ที่โรงงานหรืออยู่บ้านก็สั่งพิมพ์งานได้ และเป็นบริษัท ผู้ผลิต 3D Printer รายแรกที่ได้รับรองมาตรฐาน ISO 27001 ให้ลูกค้ามั่นใจถึงความปลอดภัยของระบบจัดเก็บข้อมูล นอกจากนี้ยังนำระบบ Artificial Intelligence (AI) มาใช้ร่วมกับระบบ Inspection ชิ้นงานอัตโนมัติในเครื่องพิมพ์บางรุ่น ยิ่งลูกค้าพิมพ์งานมากเท่าไหร่เครื่องก็จะยิ่งเรียนรู้ ยิ่งฉลาดและพิมพ์งานได้แม่นยำมากขึ้นเรื่อย ๆ และล่าสุดมีซอฟท์แวร์ Simulation ที่ช่วยจำลองความแข็งแรงของชิ้นงาน 3D Print จากเดิมต้องมานั่งเดาและลองผิดลองถูกเอง ก็สามารถใช้ Simulation ทดสอบให้ชัวร์ก่อนพิมพ์งาน ลดค่าวัสดุและเวลาในการลองผิดลองถูกได้มหาศาล

Article by: MEGA Tech & Cerathai Co., Ltd. << Click