เมื่อกล่าวถึง เครื่องจักรซีเอ็นซี CNC 5 แกนที่มีประสิทธิภาพสูงสำหรับ อุตสาหกรรมอากาศยาน ทั้งด้านทรงพลัง ฉับไว ประหยัดเนื้อที่ และใช้งานได้อย่างสากลนั้น เครื่องจักรแบรนด์ DMG MORI รุ่น DMU 340 Gantry และ DMU 200 นั้น เหมาะสำหรับเพิ่มการผลิตอย่างสูงสุด

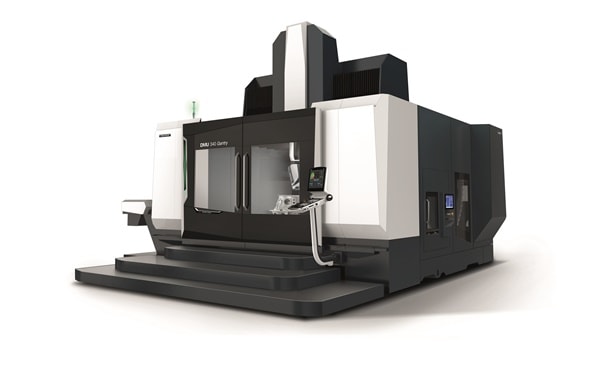

DMU 340 Gantry

เสถียร: ด้วย machine bed แบบ thermo-symmetrical ชิ้นเดียวรุ่น EN-GJS-600 เพื่อความทนทานและแม่นยำ

ฉับไว: ด้วย linear drive ที่ฉับไวและไม่สึกหรอ ทั้งแกน X และ Y ด้วยความเร็ว (rapid traverse) สูงถึง 0.5 G และ 90 m/min (เลือกเสริมได้) มี ram ที่มาพร้อมกับแกน C ในตัวเพื่อเป็น drive โดยตรงเพื่อความฉับไวสูงสุดใน เครื่องจักรแมชชีนนิ่งซีเอ็นซี CNC 5 แกน ที่ทำงานพร้อมกัน

เป็นโมดูล: สามารถขยายได้ถึง 6,000 mm ในแนวแกน X และ 1,500 mm ในแนวแกน Z

ความยืดหยุ่น: หัวกัดแกน B ที่มาพร้อม direct drive และมี swivel plane ขนาด 50 องศา เพื่อการทำงานในมุมต่างๆ จนถึงมุม -10 องศา

ทรงพลัง: มีโมดูล spindle ให้เลือกมากมายหลากหลาย พร้อมกับ HSK-A100 motor spindle ที่ระดับการหมุนสูงถึง 130 Nm

ฉลาด: ด้วยระบบ CELOS เพื่อการทำงานอย่างง่ายดาย ซึ่งผนวกเป็นองค์รวมเข้ากับการจัดการในบริษัทและการทำงาน IoT อย่างต่อเนื่อง

สำหรับ Markus Piber ซึ่งเป็น Divisional Board Member ด้านฝ่ายขายและความเป็นเลิศทางด้านเทคโนโลยีของ DMG MORI Management GmbH นั้น กล่าว่า DMU 340 Gantry รุ่นใหม่นี้ถือเป็นผลลัพธ์ที่น่าประทับใจจากความร่วมมือกันแบบลงรายละเอียดเจาะลึกกับผู้ผลิตชิ้นส่วนรายใหญ่ทั้งหลายในด้านอุตสาหกรรมอากาศยาน ผนวกกับวิศวกรรมศาสตร์เครื่องกลทั่วไป พร้อมกับการผลิตเครื่องมือและแม่พิมพ์

DMU 340 Gantry ใช้ SK40 speedMASTER motor spindle เป็น spindle ที่ DMG MORI ออกแบบและผลิตขึ้นมา พร้อมกับความสามารถ 15,000 rpm และ 130 Nm โดยที่ spindle module สามารถเลือกการเชื่อมต่อ แบบหลากหลายช่วยให้เครื่องจักรทำงานได้ตามการใช้งานเฉพาะด้าน HSK-A63 speedMASTER spindles ยังสามารถเลือกความเร็วรอบขึ้นไปจนถึง30,000 rpm หรือถึง 79 kW สำหรับประสิทธิภาพการตัดเฉือนขั้นสูงพร้อมผิวงานที่ดีเยี่ยมในคราวเดียวกัน ซึ่งความสามารถเหล่านี้เป็นที่ต้องการในสายงานอุตสาหกรรมอากาศยาน โดย HSK-A100 spindles ที่มี 430 Nm torque ซึ่งเหมาะกับการใช้งานเครื่องจักแมชีนนิ่งที่ต้องการกำลังสูง โดยเฉพาะอุตสาหกรรมการผลิตแม่พิมพ์ถือว่าเป็น spindles ที่มีประสิทธิภาพสูง และมีช่องสำหรับใส่ Tools ถึง 30 ชิ้นใน chain magazine เป็นอุปกรณ์มาตรฐานให้ด้วย ซึ่งตัว wheel magazine สามารถเลือกซื้อเพิ่มเติมได้ จะให้มีที่ว่างมากพอสำหรับใส่เครื่องมือจำนวน 63 Tools และขยายช่องเก็บเครื่องมือได้ถึง 183 ช่อง

สำหรับ เครื่องจักร DMG MORI รุ่น DMU 340 Gantry ควบคุมการสั่งงานด้วยระบบ CELOS เหมือนกับเครื่องรุ่นอื่นๆ โดยการควบคุมผ่านแอปและระบบหน้าจอทำงานจะมาพร้อมกับหน้าจอสัมผัส 21.5 นิ้ว และ CELOS APPs ทั้งหมด 27 ตัว ซึ่งจะช่วยให้ผู้ใช้งานเครื่องจักรสามารถจัดการคำสั่งและดำเนินการต่างๆ ได้อย่างดีเยี่ยม CELOS เป็นเหมือน interface (หรือตัวประสาน) การทำงานของเครื่องจักรให้เข้ากับการจัดการในบริษัทและทำให้เกิดการปฏิสัมพันธ์ในเครือข่ายการผลิตในอนาคต นอกจากนี้แล้ว ยังมีเครื่องจักรอันชาญฉลาดเพื่อ optimize กระบวนการผลิตให้ได้ผลลัพธ์ที่ดีที่สุด และช่วยเพิ่มความน่าเชื่อถือในกระบวนการยิ่งขึ้น โดยจะมี probe วัดแบบอินฟราเรด การวัดเครื่องมือในพื้นที่ทำงาน การควบคุมดูแลความเสียหายหรือแตกหักของเครื่องมือกล และระบบ Machine Protection Control (MPC) เพื่อป้องกันไม่ให้เครื่องมือชนกัน

DMU 200 Gantry

ฉับไว: เร่งในระดับ 0.5 G และความเร็ว 50 m/min (X/Y/Z)

พื้นที่ทำงานใหญ่: เส้นทางที่เคลื่อนที่ได้มีขนาด 2,000 x 2,000 x 1,200 mm in. (X/Y/Z) ซึ่งสามารถเพิ่มเป็น 4,000 mm ในแกน X ได้

มีความเสถียรสูง: Machine bed แบบเหล็กหล่อ

โต๊ะรับน้ำหนักชิ้นงานสูง: รับน้ำหนักชิ้นงานถึง 10,000 kg

ระดับความยืดหยุ่นสูง: หัวกัด 45 องศา หรือ 90 องศา สำหรับเครื่องแมชชีนนิ่ง 5 แกน ความสามารถสูงถึง 30,000 rpm

บูรณาการเทคโนโลยี: สามารถเพิ่ม ULTRASONIC ผนวกเข้าไปในเครื่องมือแมชชีนนิ่ง CFRP/GRP หรือ LASERTEC Shape สำหรับงานพื้นผิวได้

DMU 200 Gantry จาก DMG MORI รวมการทำงาน แมชชีนนิ่ง ขององค์ประกอบต่างๆ และสามารถทำงานได้อย่างฉับไวสูงสุด ในแบบที่ทำให้ประทับใจ ผู้ใช้จะได้รับประโยชน์ ในอุตสาหกรรมเครื่องบินและยานยนต์ และในภาคส่วนที่ทำแม่พิมพ์และพลังงาน ด้วย เครื่องแมชชีนนิ่งซีเอ็นซี CNC 5 แกน ความสามารถสูงถึง 30,000 rpm เมื่อผนวกเข้ากับ ULTRASONIC หรือเทคโนโลยี LASERTEC จะช่วยให้สามารถสร้างและผลิตผลงานที่ซับซ้อนกว่าเดิมได้ หนักถึง 10,000 kg ทำจากอลูมิเนียมหรือวัสดุผสมและองค์ประกอบอื่นๆ ที่เชื่อมเข้าด้วยกันได้อย่างคุ้มค่า ผู้ใช้สามารถโหลดเครื่องจักรจากด้านบนได้อย่างง่ายดายโดยใช้เครน การออกแบบ DMU 200 Gantry ให้เป็น gantry แบบต่ำ ช่วยทำให้สามารถใช้งานพื้นที่ทำงานได้อย่างมีประสิทธิภาพสูงสุด เครื่องจักรสามารถเดินทางได้ถึง 2,000 x 2,000 x 1,200 mm และนี่คือสิ่งที่ DMG MORI ทำสำเร็จเพื่อตอบโจทย์ของการทำงานผลิตภัณฑ์ระหว่างรุ่น DMF และ DMU P การผสมผสาน machine bed แบบเหล็กหล่อเข้ากับ gantry portal ถือเป็นพื้นฐานหลักที่ทำให้สามารถทำงานได้อย่างฉับไว ด้วยความเร็วสูงสุดถึง 50 m/min และอัตราการเร่ง 0.5 G ทำให้สามารถผลิตชิ้นงานขนาดใหญ่ได้อย่างมีประสิทธิภาพ และหัวกัดมีให้เลือก 2 แบบสำหรับเครื่องจักรแมชชีนนิ่งแบบ 5 แกน ขึ้นอยู่กับประเภทของการใช้งาน ได้แก่หัวกัดขนาด 45 องศา และขนาด 90 องศา หัวกัดขนาดแรกสามารถใช้งานได้ดีที่สุดในบริเวณพื้นที่ทำงาน ส่วนหัวกัดขนาด 90 องศา ช่วยให้สามารถใช้งาน spindle ได้เหมาะกับงานเฉพาะด้าน เช่น ใช้กับ compactMASTER ที่มีความเร็วในการหมุน 20,000 rpm เป็นมาตรฐานในรุ่น 5 แกน ตัวเลือก spindle อื่นๆ ที่มีเพิ่มเติมจะมีความเร็วหมุนที่ 24,000 rpm, 28,000 rpm และ 30,000 rpm ส่วน DMU 200 Gantry รุ่นที่มีแกน 3 แกนแนวตั้งจะมาพร้อมกับ speedMASTER spindle ที่มีความเร็ว 20,000 rpm และสามารถเพิ่มหัวกัด ULTRASONIC และเทคโนโลยี LASERTEC Shape ได้ ซึ่งเทคโนโลยีนี้จะใช้เพื่อผลิตชิ้นส่วนที่พิมพ์แบบแล้ว (molded parts) รวมทั้งใช้กับการทำโครงสร้างผิว (surface structuring)

Article by: DMG Mori (Thailand) Co., Ltd & MEGATech