เป็นที่ทราบกันดีว่าการลดระยะเวลาในการผลิตและการลดต้นทุน ถือเป็นปัจจัยสำคัญในการผลิตของอุตสาหกรรมการขึ้นรูปโลหะยานยนต์ ในทางกลับกัน ด้วยปัจจุบัน วิศวกรรมการออกแบบสำหรับการผลิตยานยนต์นั้นเป็นอุตสาหกรรมที่มีความหลากหลาย ทำให้อุตสาหกรรมการขึ้นรูปโลหะยานยนต์จำเป็นต้องพัฒนาเทคโนโลยีให้มีความแม่นยำที่สูงมากขึ้น และจำต้องมีข้อกำหนดด้านการตรวจสอบคุณภาพพื้นผิวชิ้นงานที่ได้จากการขึ้นรูปโลหะยานยนต์ที่มากขึ้น เพื่อให้ก้าวทันต่อความหลากหลายดังกล่าว ในขณะเดียวกันนั้นเอง กระบวนการการขึ้นรูปโลหะยานยนต์นั้นต้องอาศัยฝีมือ ความรู้ และความเชี่ยวชาญเฉพาะ เช่น งานขัดขึ้นเงาและลบรอย และการประกอบชิ้นงานที่ขึ้นรูปแล้ว เป็นต้น ซึ่งความเชี่ยวชาญเหล่านี้กำลังจะสูญหายไป สวนทางกับที่อุตสาหกรรมการขึ้นรูปโลหะยานยนต์นั้น ต้องผลิตชิ้นงานให้ได้คุณภาพสูง และต้องมีการปรับปรุงประสิทธิภาพการผลิตให้ทันสมัยอยู่อย่างสม่ำเสมอ

จากนี้ไป จะขอนำท่านเข้าสู่บทความที่จะแนะนำความสามารถสุดยอดของ Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ เพื่อการขึ้นรูปโลหะยานยนต์ หรือ ดับเบิ้ล แมชชีนนิ่ง เซนเตอร์-ซูปเปอร์ (MCR-Super) หรือ “MCR-S” และเทคโนโลยีอื่นๆที่เกี่ยวข้อง ซึ่งถูกพัฒนาขึ้นเพื่อร่นระยะเวลาของกระบวนการผลิตของอุตสาหกรรมการขึ้นรูปโลหะยานยนต์

วัตถุประสงค์ของการพัฒนา

Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S เป็นเครื่องที่พัฒนามาเพื่อใช้ขึ้นรูปโลหะสำหรับใช้ในอุตสาหกรรมยานยนต์ ซึ่งการลดระยะเวลาในการผลิตเพื่อให้ได้ผลผลิตที่เร็วขึ้นถือเป็นเรื่องสำคัญที่ต้องคำนึงถึงเป็นอันดับต้นๆในอุตสาหกรรมการขึ้นรูปโลหะยานยนต์ มากไปกว่านั้น ด้วยนวัตกรรมการออกแบบยานยนต์ในยุคปัจจุบันที่กำลังพัฒนาไปอย่างต่อเนื่อง ทำให้เทคโนโลยีการกลึงและขึ้นรูปพื้นผิว จึงเป็นสิ่งที่มีความจำเป็นอย่างมากเช่นกัน ดังนั้น การพัฒนา Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S จึงจำเป็นอย่างยิ่งยวดเพื่อจัดการกับปัญหาที่อาจจะเกิดขึ้นตามมาได้

เทคโนโลยีหลักเพื่อการแก้ไขปัญหา

- ลดระยะเวลาทำงาน

สำหรับการผลิตชิ้นงานโดยใช้เครื่องขึ้นรูปโลหะยานยนต์แบบกลึงภายนอก (outer type) อาทิ การกลึงฝากระโปรงรถยนต์ และแผงข้างตัวถัง จะพบรอยย่นของแผ่นโลหะได้น้อยกว่ามาก ทำให้คิดได้ว่าการเพิ่มความเร็วของการป้อนแผ่นโลหะเข้าเครื่องกลึงนั้น จะช่วยลดระยะเวลาของกระบวนการทำงานได้จริง ด้วยเหตุนี้ เทคโนโลยีของเครื่องขึ้นรูปโลหะยานยนต์ MCR-S จึงได้ถูกคิดค้นขึ้น ด้วยการเร่งความเร็วของการตัดอย่างต่อเนื่องสูงสุดที่ 20 เมตรต่อนาที สำหรับการตัดในแกน X กับ แกน Y และสามารถตัดได้เร็วต่อเนื่องที่ 10 เมตรต่อนาที สำหรับแกน Z ทำให้ Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S ถูกจัดอยู่ในเครื่องขึ้นรูปโลหะยานยนต์ที่ทำงานไวที่สุดในเครื่องที่อยู่ระดับเดียวกัน

ในขณะเดียวกัน เมื่อนำเครื่องขึ้นรูปโลหะยานยนต์ Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S ที่เป็นเทคโนโลยีสมัยใหม่นี้ ไปใช้อุตสาหกรรมการผลิตแผงข้างสำหรับอุตสาหกรรมยานยนต์ เมื่อนำไปเปรียบเทียบกับการทำงานของเครื่องจักรรุ่นเก่าแล้วสามารถช่วยลดระยะเวลาในกระบวนการผลิตได้กว่า 25% เลยทีเดียว

2. ก้าวหน้ากว่าด้วยการยกระดับคุณภาพของชิ้นงาน

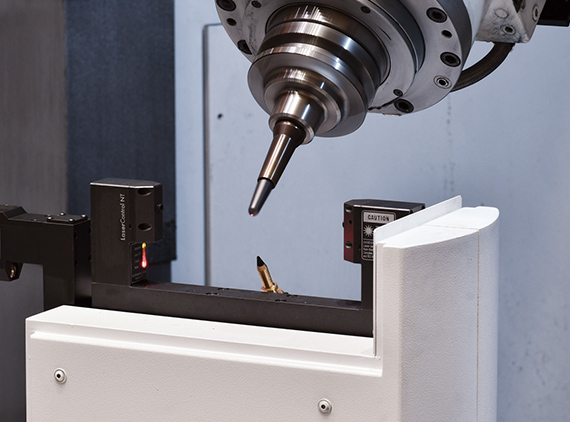

นอกจากการลดระยะเวลาในกระบวนการขึ้นรูปโลหะยานยนต์แล้ว การลดระยะเวลาในการขัดลบรอยชิ้นงาน ด้วยเทคโนโลยีที่ทำให้ชิ้นงานออกมาไร้รอยขีดข่วน แม้ผ่านกระบวนการตัดมาแล้ว ก็เป็นเรื่องจำเป็นสำหรับอุตสาหกรรมยานยนต์เช่นกัน Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S ให้คุณได้มากกว่า ด้วยเทคโนโลยีการวาดเส้นนำร่องก่อนการตัดที่แกน Y และระบบระบายความร้อนที่รางเข็มตอกสำหรับการผลิตชิ้นงานในแกน Z เพื่อเพิ่มประสิทธิภาพในการเคลื่อนไหวในการตัดของแต่ละแกน ดังนั้น ชิ้นงานที่ได้จึงไร้รอยขีดข่วน มีความถูกต้องแม่นยำ และได้ชิ้นงานที่พื้นผิวมีคุณภาพสูงกว่ารุ่นเดิมๆ

ยกตัวอย่างเช่น จากการประเมินและตรวจสอบคุณภาพชิ้นงานที่ได้จากการกระบวนการตัดแต่งที่แกน Z ด้วยกล้องตรวจสอบแบบ 3 มิติ (3D optical profiler) จากการใช้เครื่องขึ้นรูปโลหะยานยนต์รุ่นเก่า จะพบร่องรอยลึกกว่า 1 ไมโครเมตร ในขณะที่เมื่อตรวจสอบชิ้นงานที่ได้จาก Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S พบร่องรอยลึกเพียง 0.5 ไมโครเมตรหรือน้อยกว่านั้น และไม่สามารถตรวจพบร่องรอยใดใดขึ้นเลยในบางชิ้นงาน (รูปภาพที่ 2)

นอกจากตัวเครื่อง Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S จะมีความทันสมัยและมีประสิทธิภาพในการส่งมอบคุณภาพชิ้นงานที่ไร้ที่ติและมีคุณภาพสูงแล้ว Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S ยังมาพร้อมกับโปรแกรมการควบคุมการทำงาน และระบบประมวลผลก็มีความสำคัญไม่แพ้กันอีกด้วย

เราขอแนะนำให้ท่านรู้จักกับ “Hyper-Surface” ระบบการทำงานที่มาพร้อมกับเครื่อง Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S ซึ่งจะช่วยทำให้ชิ้นงานของคุณมีคุณภาพมากยิ่งขึ้น ด้วยการควบคุมระบบการทำงานของเครื่องและปรับแก้ไขข้อมูล NC ให้มีความถูกต้องอย่างอัตโนมัติตลอดระยะเวลาที่เครื่องกำลังทำงานอยู่ เพื่อให้พื้นผิวของชิ้นงานที่ได้มีคุณภาพ

โดยเฉพาะอย่างยิ่ง “Hyper-Surface” จะช่วยเพิ่มคุณภาพของชิ้นงานด้วยการปรับแก้ขนาดของช่องว่างระหว่างเส้นทางการเดินของหัวตัดที่ไม่เสมอกัน ยิ่งไปกว่านั้น “Hyper-Surface” ยังช่วยลดความลึกรวมถึงความกว้างของขอบที่ไม่สอดคล้องกันด้วยการเปลี่ยนแปลงระดับความลึกของการตัด และจะทำการจัดเรียงให้กลับมาสอดรับกัน เพื่อยับยั้งการเกิดร่องรอยลึกบนพื้นผิวของชิ้นงาน (รูปภาพที่ 3) ด้วยเหตุผลนี้เอง Double Column Machining Center แมชชีนนิ่งเซ็นเตอร์แบบเสาคู่ MCR-S จะทำให้ชิ้นงานที่ได้มีคุณภาพดีและยังช่วยลดระยะเวลาของกระบวนการขัดลบรอยลงได้อย่างมากจนน่าประทับใจ

Fig.2 Trackability Improvement Result

Article by: Okuma Techno (Thailand) Ltd. & MEGA Tech