เครื่อง CNC ที่ให้ความเที่ยงตรงสูง อีกทั้งยังสามารถเชื่อมต่อกับอุปกรณ์เสริมอื่น เพื่อตอบโจทย์การผลิตได้มากขึ้น ทาง MEGA Tech ขอนำเสนอ เครื่อง CNC รุ่น XT-8MY จาก Takamaz ที่มีนวัตกรรมใหม่ล่าสุดเข้ามาตอบโจทย์ นอกจากนี้ยังมี ระบบจาก FANUC ที่เข้ามาสนับสนุนให้เครื่อง CNC จาก Takamaz มีประสิทธิภาพมากยิ่งขึ้น

ธุรกิจหลักประกอบด้วยการผลิต การจำหน่าย และการให้บริการ/บำรุงรักษาเครื่องจักร CNC โดยนับตั้งแต่ก่อตั้งบริษัทในปี 1958 Takamaz ได้ทุ่มเทปรับปรุงเทคโนโลยีภายใต้หลักปรัชญา “พัฒนาเครื่องจักรที่จะช่วยสร้างกำไรให้แก่ลูกค้า” ในปัจจุบัน บริษัทมีลูกค้ามากมายทั้งในและนอกประเทศที่มั่นใจเลือกใช้เครื่องCNC ของ Takamaz เนื่องจากมีความเที่ยงตรงสูง

คำว่า “เครื่องมือกล” หมายถึง เครื่องจักรที่ใช้ในการผลิตชิ้นส่วนต่างๆ โดยการเจาะหรือการตัดเฉือนก้อนโลหะเป็นหลัก โดยจะมีการแบ่งออกเป็นประเภทต่างๆ ขึ้นอยู่กับลักษณะงาน เครื่องมือกลมักจะถูกเรียกว่า “เครื่องจักรสำหรับสร้างเครื่องจักร” หรือ “เครื่องจักรแม่” เนื่องจากใช้สำหรับตัดเฉือนชิ้นส่วนที่นำมาผลิตเป็นเครื่องจักรอื่นๆ ซึ่งมีบทบาทสำคัญอย่างมากต่ออุตสาหกรรมการผลิต

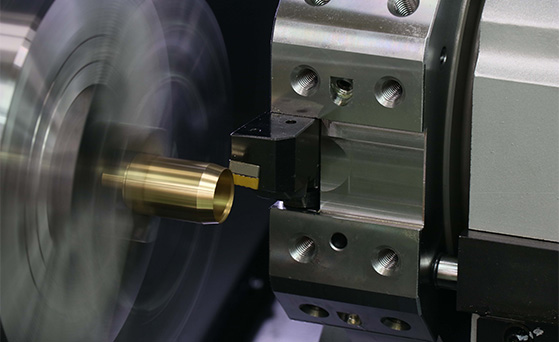

หนึ่งในเครื่องมือกลที่ Takamaz ผลิต ได้แก่ เครื่องกลึงระบบ CNC โดยเครื่องกลึงนั้นเป็นเครื่องมือกลที่ใช้มีดตัดเฉือนชิ้นงานที่กำลังหมุนอยู่ เพื่อเฉือนเนื้อวัสดุส่วนที่ไม่ต้องการออก ส่วนเครื่องกลึงระบบ CNC หมายถึงเครื่องมือกลลักษณะดังกล่าวที่มีการติดตั้งระบบคอมพิวเตอร์ควบคุมการทำงาน การใช้คอมพิวเตอร์ควบคุมการเคลื่อนที่ของมีดกลึงจะช่วยให้งานตัดเฉือนมีความเที่ยงตรงสูงถึง 1/1000 มม.

เครื่องกลึงเป็นเครื่องจักรที่ตัดเฉือนชิ้นงานโดยการเคลื่อนมีดกลึงเข้าหาชิ้นงานทรงกระบอกที่กำลังหมุนอยู่ ซึ่งเป็นวิธีการเดียวกับการทำตุ๊กตาไม้โคเคชิของญี่ปุ่น เครื่องกลึงที่ใช้คอมพิวเตอร์ในการควบคุมการเคลื่อนที่ของมีดกลึงจะเรียกว่า เครื่องกลึงระบบ CNC โดยคำว่า CNC ย่อมาจาก Computerized Numerical Control (การควบคุมเชิงตัวเลขด้วยคอมพิวเตอร์) โดยหมายถึงการควบคุมเครื่องจักรโดยอัตโนมัติด้วย “ข้อมูลตัวเลข” ซึ่งประกอบไปด้วยค่าและโค้ดต่างๆ เครื่องกลึงระบบ CNC เป็นหัวใจสำคัญของกระบวนการผลิตในทุกอุตสาหกรรม เช่น การผลิตรถยนต์และเครื่องใช้ภายในบ้าน เครื่องกลึง CNC จากญี่ปุ่นถือเป็นเครื่องกลึงที่มีส่วนแบ่งตลาดมากที่สุดในโลกด้วยระบบคอมพิวเตอร์ควบคุมที่ให้ความแม่นยำของการตัดเฉือนในระดับไมครอน ผลิตภัณฑ์ที่ผลิตขึ้นจากชิ้นส่วนที่ผ่านการตัดเฉือนความเที่ยงตรงสูงสามารถที่จะสร้างผลกำไรได้มากกว่า เนื่องจากมีคุณภาพสูงกว่าผลิตภัณฑ์อื่นๆ ในตลาด นอกจากเครื่องกลึง CNC จะเป็นพื้นฐานสำคัญในการผลิตผลิตภัณฑ์ต่างๆ แล้ว ยังถือเป็นพื้นฐานสำคัญของเศรษฐกิจด้วยเช่นกัน

ในส่วนของการเปลี่ยนกระบวนการผลิตแบบใช้คนควบคุมมาเป็นระบบอัตโนมัติ Takamaz มีผลิตภัณฑ์เครื่องกลึง ระบบ CNC พร้อมด้วยอุปกรณ์เสริมต่างๆ ที่Takamazพัฒนาขึ้นเอง รวมไปถึงระบบสายการผลิตออกแบบเฉพาะสำหรับลูกค้าแต่ละราย ซึ่งมีการเชื่อมต่อเครื่องจักรหลายเครื่องเข้าด้วยกันเป็นระบบเดียว

ระบบสายการผลิตพร้อมเทคโนโลยีออโตเมชั่นที่ออกแบบมาโดยเฉพาะสำหรับลูกค้าแต่ละราย

ระบบสายการผลิตของ Takamaz ได้รับความเชื่อถืออย่างสูงจากลูกค้า เนื่องจากTakamazสามารถตอบสนองความต้องการของลูกค้าได้อย่างละเอียดครบถ้วนด้วยการใช้อุปกรณ์เสริมที่ Takamaz ออกแบบขึ้นเอง ซึ่งต่างไปจากบริษัทอื่นๆ

เครื่องกลึง CNC ความเที่ยงตรงสูง XT-8MY [8 นิ้ว] 1 สปินเดิล 1 ป้อมมีด นวัตกรรมระบบ CNC ใหม่ล่าสุดจาก TAKAMAZ

เครื่องกลึงแบบผสมขนาดเล็กพร้อมแกน Y ให้ประสิทธิภาพเหนือกว่า

รองรับงานกลึงเพลายาวได้สูงสุด 300 มม. ด้วยขนาดเครื่องเล็กที่สุดเมื่อเทียบกับเครื่องจักรระดับเดียวกัน

รองรับงานกลึงเพลายาวสูงสุด 300 มม. พร้อมรางสไลด์สี่เหลี่ยมสำหรับทุกแกน เพื่อให้โครงสร้างมีความแข็งแรงสูงสุด สามารถเลือกขนาดยันศูนย์ท้ายได้ ตัวเครื่องใช้พื้นที่ติดตั้งน้อยที่สุดเมื่อเทียบกับเครื่องจักรระดับเดียวกัน โดยใช้พื้นที่น้อยกว่าเครื่องจักรยี่ห้ออื่นประมาณ 20%

ประสิทธิภาพสูงสำหรับเครื่องมือหมุน (ป้อมมีด BMT)

มอเตอร์ชุดกัด AC ให้กำลัง 5.5/3.7/2.2 กิโลวัตต์ รองรับขนาดเครื่องมือสูงสุด φ20 มม. ให้ประสิทธิภาพการผลิตสูงยิ่งขึ้นป้อมมีดใช้ระบบยึดด้วยโบลท์ (BMT55) ช่วยลดระยะเวลาที่ใช้ในการปรับตั้ง พร้อมระบบ Half-Index ที่ช่วยให้ติดตั้งเครื่องมือได้สูงสุด 24 ชิ้นและลดระยะเวลาที่ใช้ในการติดตั้ง (ติดตั้งเครื่องมือหมุนได้สูงสุด 12 ชิ้น)

ติดตั้ง F Loader รุ่นใหม่ได้

เพิ่มความสะดวกในการใช้งานด้วยการควบคุมทั้งตัวเครื่องจักรและอุปกรณ์อัตโนมัติจากส่วนกลางผ่านระบบ FANUC มีระบบอัตโนมัติที่ช่วยเพิ่มทั้งความสะดวกและความเชื่อถือได้ รวมถึงการปรับตั้งที่ทำได้รวดเร็วยิ่งขึ้นด้วยฟังก์ชั่นย้อนตำแหน่งด้ามจับ

ใช้ระบบปฏิบัติการ TAKAMAZ (F Loader Specifications)

นอกจากหน้าจอในแบบของ FANUC แล้ว ยังมีฟังก์ชั่นที่ออกแบบมาเพื่อเพิ่มประสิทธิภาพให้กับเครื่องจักรอัตโนมัติด้วยเช่นกัน โดยมีการเพิ่มฟังก์ชั่นสนับสนุนที่จะช่วยให้การปรับเครื่องมือสำหรับงานตัดเฉือนโลหะมีความปลอดภัยและสะดวกมากยิ่งขึ้น รวมไปถึงฟังก์ชั่นติดตามการทำงานที่จะทำหน้าที่บันทึกสถานะการทำงานเอาไว้โดยอัตโนมัติ เพื่อเพิ่มประสิทธิภาพให้กับการบำรุงรักษาเชิงป้องกัน

ชุดอุปกรณ์สำหรับงานตัดเฉือนเพลา

ชุดอุปกรณ์ต่างๆ ไม่ว่าจะเป็นชุดยันศูนย์ท้าย เช่น ยันศูนย์ท้ายแบบขับด้วยเซอร์โวหรือยันศูนย์ท้ายในตัวไปจนถึงแท่นประคอง เพื่อช่วยเพิ่มประสิทธิภาพให้กับงานตัดเฉือนประเภทต่างๆ

Article by : Takamatsu machinery (Thailand) co.,ltd. & MEGA Tech