เมื่อเปลี่ยนจากการผลิตแบบแนวตั้งไปเป็นแนวนอนถึงแม้ว่าจะมีราคาแพงกว่าที่หลายๆโรงงานจะคาดไว้ แต่ด้วยผลผลิตมีคุณภาพมากกว่าเป็นเหตุผลสำคัญที่ทำให้ในหลายๆโรงงานได้นำเครื่อง HMCs มาใช้งานในปัจจุบัน

เครื่องแนวนอนโดยทั่วไปมีมาตรฐานที่มาพร้อมกับแท่นวางสินค้าที่เคลื่อนย้ายได้เพื่อป้อนชิ้นงานเข้าเครื่อง ในขณะที่ชิ้นงานชิ้นแรกบนแท่นวางสินค้ากำลังทำงาน แท่นวางสินค้าอื่นๆจะสามารถโหลดชิ้นงานใหม่เข้ามาเตรียมไว้ เมื่อครบรอบการผลิตชิ้นงานแรก แท่นวางสินค้าจะถูกเปลี่ยนอย่างอัตโนมัติทำให้ไม่เสียเวลาในการทำงาน นอกจากนี้ HMCs ยังสะดวกในเรื่องของความยืดหยุ่นและหลากหลายในการยึดจับชิ้นงาน ได้ตั้งแต่ 4, 6 และ 8 ชิ้นพร้อมกัน การยึดจับแบบคู่และ ระบบ dedicated hydraulic หรือ high-density fixturesซึ่งเป็นระบบภายในที่มีอยู่ในเครื่อง HMCs มาตรฐานโดยทั่วไป ซึ่งเป็นที่ชื่นชอบกับผู้ผลิตเนื่องจากสามารถผลิตชิ้นงานในปริมาณสูงได้อย่างรวดเร็ว ผู้ผลิตที่ผลีตชิ้นงานต้นแบบหรือชิ้นงานที่มีปริมาณต่ำยังด้รับประโยชน์จากการติดตั้งชิ้นงานหลายๆชิ้นภายในแต่ละแท่นบนเครื่อง HMCs

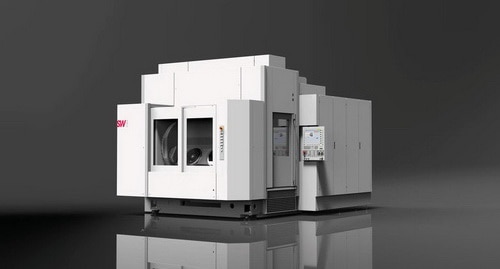

2, 4-fold productivity with the twin spindle machine BA 622 of SW

Schwäbische Werkzeugmaschinen GmbH (SW) นำเสนอโซลูชั่นที่ครอบคลุมทุกเทรนความต้องการ ด้วยเครื่องแมชชีนนิ่งเซนเตอร์แนวนอน 2 หัวสปินเดิลที่ได้รับการออกแบบเพื่อการผลิตชิ้นงานจำนวนมาก ในรุ่นนี้รวบรวมความสามารถในการผลิตที่ให้ความแม่นยำสูงกว่า พร้อมด้วยประสิทธิภาพการใช้พลังงานและเพิ่มประสิทธิภาพการผลิตโดยรวมได้ถึง 20% เมื่อเทียบกับเครื่องสปินเดิลแบบหัวเดียวที่นำเสนอแท่นจับชิ้นงาน 2 และ 4 แท่นซึ่งจะช่วยให้ต้นทุนการผลิตต่ำกว่า เครื่อง BA 622 ได้เปิดมิติใหม่เพื่อผลผลิตที่ยอดเยี่ยมสำหรับผู้ผลิต OEMs ที่ต้องการการผลิต 4 แกนและ 5 แกนให้กับวัสดุชิ้นงานจำพวกเหล็กและเหล็กหล่อที่ขนาดไม่เกิน 600 มิลลิเมตร เมื่อ เปรียบเทียบกับเครื่องในรุ่นเดิม BA 600 จะพบว่ามีประสิทธิภาพสูงขึ้น 20% และเมื่อเปรียบเทียบกับ แมชชีนนิ่งเซนเตอร์หัวเดียวจะพบว่า BA622 มีประสิทธิภาพสูงกว่า 2.4 เท่านอกจากนี้ยังให้ความแม่นยำสูงสุดและใช้พลังงานได้มีประสิทธิภาพมากที่สุดอีกด้วย ด้วยประสิทธิภาพการผลิตที่เพิ่มขึ้นอย่างมากของ BA622 ทำให้มันสามารถผลิตชิ้นงานด้วยความเร่งสูงจากความเร็วเดิม 2-3 เท่าทุกแนวแกน การทำงานของหัวสปินเดิลให้ความเร็วสูงสุดมากกว่าเดิม 25% ใช้เวลาในการหมุนรอบเพียง 3.75 วินาที ซึ่งจะลดเวลาในการทำงานแต่ละรอบการผลิตของคุณได้ทั้งหมด

โครงสร้างพื้นฐานในการออกแบบ monoblock ช่วยลดการโค้งงอภายใต้สภาวะโหลดสูงและรับประกันได้ว่าที่ยึดจับชิ้นงานจะให้แรงในการจับยึดที่เหมาะสมในระหว่างการผลิตชิ้นงาน ด้วยหลักการจะเป็นการสร้างเลี่อนไขเบื้องต้นเพื่อการปรับปรุงการเคลื่อนที่แบบไดนามิกและความแม่นยำให้กับการผลิตชิ้นงานที่ยากต่อการผลิตแนวแกน Y จะอยู่ในตำแหน่งของระบบการขับเคลื่อนร่วมกับระบบการตรวจวัดระยะแม่นยำสูง

MULTISWISS – 32 mm, 19 Nm, perfect for large diameters

Tornos นำเสนอเครื่องไซส์ใหญ่ขนาด XL ที่ใช้มัลติสปินเดิลในการกลึงโดยมีให้เลือก 2 รุ่นนั่นคือ MultiSwiss 8×26 และ MultiSwiss 6×32.

Tornos ได้ขยายรุ่นการผลิตให้กับเครื่อง MultiSwiss ที่สามารถรองรับการผลิตชิ้นงานที่เส้นผ่าศูนย์กลางตั้งแต่ 4-32 มิลลิเมตร ทั้ง 2 รุ่นใหม่ล่าสุดนี้ได้รับการออกแบบด้วยแนวความคิดและเทคโนโลยีที่มีประสบความสำเร็จมาแล้วในเครื่องรุ่น MultiSwiss 6×14 และ MultiSwiss 6×16 ด้วยรุ่นใหม่ล่าสุด MultiSwiss 8×26 และ 6×32 ได้มีการติดตั้ง sliding headstock spindle ในแนวแกน Z เพิ่มเติม barrel indexingด้วย มอเตอร์ทอร์ก และส่วนระกอบภายนอกทั้งหมดจะเป็นไปตามความต้องการของผู้ใช้งานเครื่องจักร พื้นที่ใช้สอยที่เหมาะสม กระทัดรัดเหมือนกับในรุ่นเล็กกว่า เครื่องจักรใหม่จะมีการทำเครื่องหมายให้แต่กต่างจาก เครื่องจักรมัลติสปินเดิล ทั่วไป และมีช่วงว่างระหว่างการกลึงแบบมัลติสปินเดิลและสปินเดิลแบบเดี่ยว เทคโนโลยีที่มีอยู่ในเครื่องจักรเหล่านี้จะมีผลต่อรอบเวลาในการขับเคลื่อนของมัลติสปินเดิล มันเป็นจะทำงานด้วยสปินเดิลอิสระทั้ง 6 ตัวพร้อมกับแบริ่งชนิด hydrostatic และสามารถรองรับชิ้นงานได้สูงสุดถึง 32 มิลลิเมตร ซึ่งให้ผลการทำงานที่ยอดเยี่ยม มอเตอร์ขนาด 11 กิโลวัตต์ได้รับการออกแบบให้มีกำลังทอร์คสูงกว่า 19.5 นิวตันเมตร ให้ความเร็วสปินเดิลสูงสุดที่ 6000 rpm และสามารถปลิตชิ้นงานได้ยาวที่สุดที่ 75 มิลลิเมตรโดยมีแท่นรองรับชิ้นงาน 3 แท่นในแกน Y