FH630SX-5A Machining Centers จาก TOYODA ทรงประสิทธิภาพในการกัดชิ้นงานได้หลากหลายและทรงพลังในการกัดชิ้นงานขนาดใหญ่ได้อย่างดีเยียมสามารถใช้ได้ในหลากหลายอุตสาหกรรม เช่น อุตสาหกรรมยานยนต์ อุตสาหกรรมการบิน รวมถึงอุตสาหกรรมที่เกี่ยวข้องกับพลังงาน และเครื่องจักรกลเพื่อการก่อสร้างและการขนส่ง

FH630SX-5A มีความสามารถในการกัดชิ้นงานที่มีรูปทรงที่ซับซ้อนและพื้นผิวที่หลากหลายแตกต่างกัน โดยการตั้งค่าการทำงานด้วย FANUC CNC controller รุ่น 31i เพื่อประมวลผลการทำงานรวมกถึงการควบคุมการทำงานของเครื่องได้โดยการตั้งค่าเครื่องในครั้งเดียว ซึ่งช่วยลดเวลาในการตั้งค่าการขึ้นรูปชิ้นงานแบบต่าง ๆ ได้รวดเร็วขึ้น สามารถผลิตชิ้นงานด้วยคุณภาพสูง มีขีดความสามารถในการผลิตสูง จึงช่วยเพิ่มประสิทธิภาพด้านการผลิตและลดต้นทุนในการผลิตได้อย่างดีเยี่ยม

คุณลักษณะเด่นของเครื่อง FH630SX-5A

■ สามารถรองรับชิ้นงานขนาดใหญ่: สามารถในกัดชิ้นงานขนาดใหญ่ หน้ากว้างสูงสุด 1,050 มม. ความสูงสูงสุด 1,600 มม. รวมถึงชิ้นงานทีมีเส้นผ่าศูนย์กลางสูงสุด Ø1,170 มม. และสามารถองรับชิ้นงานที่มีน้ำหนักสูงสุดถึง 1,500 กก.การสวิงของสปินเดลที่สามารถหมุนแกนได้สูงถึง 230º ซึ่งทำให้เครื่องจักรรุ่นนี้สามารถรองรองรับชิ้นงานขนาดใหญ่ได้อย่างดีเยี่ยม

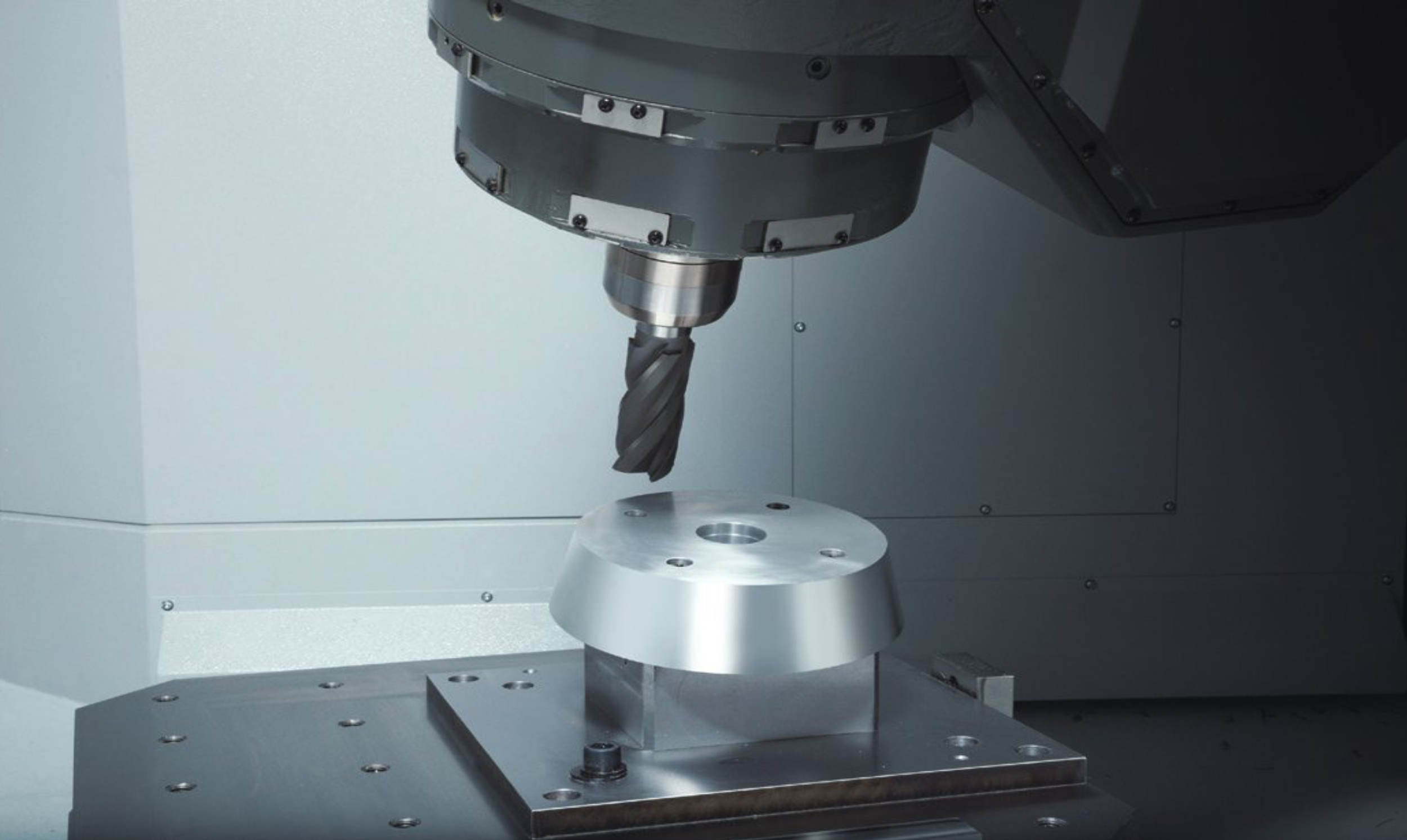

■ ประสิทธิภาพในการกัดขึ้นงานสูง: ด้วยลักษณะของแกนหมุนที่มีขนาดใหญ่ มีความยืดหยุนสูง แข็งแรง และทรงพลัง ดังนั้นเครื่อง FH630SX-5A จึงมีความสามารถในการกัดชึ้นงานได้หลากหลาย ตั้งแต่วัสดุที่หลาหลาย ตั้งแต่ชิ้นงานที่มีความแข็งแบบทั่วไป เช่น อลูมิเนียม (Aluminum) รวมไปถึงชิ้นงานที่ยากต่อการกัด เช่น อินคอแนล (Inconel) และไทเทเนียม (titanium)

FH630SX-5A มาพร้อมกับ Spindle ขนาดใหญ่ ช่วยให้ประสิทธิภาพในการกัดชิ้นงานด้วยแกนหมุนที่มีความยืดหยุ่น แข็งแรง และทรงพลัง โดย TOYODA ได้นำแกนหมุนที่สามารถเอียงกัดชิ้นงานได้ ซึ่งแกนหมุนนี้ ได้รับการถ่ายทอดมากจาก DNA ของ JTEKT ซึ่งเป็นเอกลักษณ์เฉพาะตัว และความแข็งแรงสูง รวมถึงมีโครงสร้างเครื่องจักรที่มีขนาดใหญ่และแข็งแรงพร้อมรองรับชิ้นงานทุกประเภท จึงทำให้สามารถสามารถกัดชิ้นงานที่มีขนากดใหญ่ และแข็งได้อย่างมีประสิทธิภาพ รวมถึงมีความสเถียรภาพในการกัดชิ้นงานสูง

ด้วยโครงสร้างขนาดใหญ่ของเครื่องจักรที่ช่วยรองรับการทำงานของแกนหมุนแบบ 5 แกนแล้ว เครื่องนี้ยังสามารถลดแรงสั่นสะเทือนจาก “ภายนอก” ที่มีผลต่อความแม่นยำในการประมวลผลการทำงานของเครื่องจักรได้เป็นอย่างดี ดังนั้น การที่เครื่องจักรมีโครงสร้างที่แข็งแรง จึงทำให้สามารถรองรับการกัดขึ้นงานที่เป็นวัสดุที่มีความแข็งสูงได้อย่างดีเยี่ยม รวมถึงช่วยชะลอความเร็วในการป้อนชิ้นงานได้เป็นอย่างดี

คุณสมบัติพิเศษของ Spindle ในเครื่องจักร FH630SX-5A

■ แกนหมุนแบบยืดหยุ่นได้ (แกน C): ด้วยความยืดหยุดของแกนหมุนที่สามารถเอียงหรือปรับเปลี่ยนองศาได้ รวมถึงการมีโครงสร้างโครงจักรที่มีขนาดใหญ่และแข็ง จึงทำให้สามารถโหลดชิ้นงานที่มีขนาดใหญ่ลงบนพาเลทที่รองรับชิ้นงานได้โดยม่มีผลต่ออการกัดชิ้นงาน อีกทั้งเครื่องจักรรุ่น FH630SX-5A ยังมีในส่วนของแกนหมุน ที่เป็นแกน C สามารถสวิงได้ทั้งสองฝั่งด้านข้างของแกนหมุน ดังนั้น น้ำหนักของชิ้นงานที่นำมากัดจึงไม่มีผลต่อการขึ้นรูปของชิ้นงาน นอกจากนี้แกนหมุนการเอียงของแกนหมุนยีงมีความยาวของระยะห่างในการหมุนประมาณ 100 มม. ซึ่งทำให้รัยะการเคลื่อนที่ของแกนหมุนของแกนตรงสั้นขึ้น ซึ่งช่วยให้รบบการควบคุมการกัดชิ้นงานมารถประมวลผลชิ้นงานที่มีขนาดใหญ่ได้โดยการตั้งค่าดพียงครั้งเดียว ซึ่งสะดวกต่อการบริหารจัดการทำงานของเครื่องจักร

■ การทำงานของแกนหมุนที่รองรับชิ้นงานที่หลากหลาย ด้วยความยืดหยุ่นของแกนหมุนในเครื่อง FH630SX-5A ทีสามารถรองรับการกัดชึ้นงานได้หลากหลายรูปแบบ ดังนั้นแกนหมุนของเครื่องจักรรุ่นนี้จึงถูกออกแบบมาในตำแหน่งที่เหมาะสม เพื่อให้มีความสามารถในการปรับเปลี่ยนแกนหมุนได้รูปร่างและขนาดของชิ้นงาน รวมถึงสามารถสามารถกัดชิ้นงานที่อยู่บนพาเลท ที่มีระยะห่างจากจุดศูนย์กลางถึง 300 มม. ในขณะทีแกนหมุนอยู่ตำแหน่งแนวตั้ง ซึ่งช่วยให้พื้นที่ในการกัดชิ้นงานมีขนาดกว้างมากขึ้น

Spindle ของ Toyoda สามารถกัดชิ้นงานด้วยความเร็วสูงถึง 15,000 รอบต่อนาที(min-1) ด้วยเครื่องสร้างของ Spindle ที่มีความแข็งแรง ทำให้สามารถกัดชิ้นงานได้หลากหลายชนิด ครอบคลุมตั้งแต่วัสดุที่เป็นเหล็กที่เครื่องจักรสามารถประมวลผลได้ตั้งแต่ความเร็วต่ำไปจนถึงปานกลาง ไปจนถึงวัสดุที่เป็นอลูมิเนียมที่สามารถปรับความความเร็วการการป้อนชิ้นงานด้วยความเร็วสูง นอกจากนี้เรายังมี Spindle ที่สามารถกัดชิ้นงานสูงถึง 8,000 รอบต่อนาที ซึ่งเราใช้ Ceramic Ball Bearings ซึ่งผ่านศูนย์กลางขนาดใหญ่ที่ช่วยให้สามารถการตัดชิ้นงานที่มีความแข็งแรงและกัดเจาะอยากได้ รวมถึงช่วยให้สามารถรับน้ำหนักได้มากขึ้นด้วย

Article by: Toyoda Machinery S.E. Asia Co.,Ltd. & MEGA Tech