การปรับปรุงคุณภาพ การลดเวลารอคอยสินค้า และการลดต้นทุนถือเป็นประเด็นสำคัญในอุตสาหกรรมการผลิตแม่พิมพ์ ในทางกลับกันความซับซ้อนและความหลากหลายของการออกแบบผลิตภัณฑ์ได้นำไปสู่ความเที่ยงตรงสูงของรูปร่าง และข้อกำหนดด้านคุณภาพพื้นผิวที่สูงขึ้นอย่างมากในการผลิตแม่พิมพ์ ความรู้ความชำนาญที่จำเป็นสำหรับงานตกแต่งผิวด้วยแรงงานคน เช่น การขัดเงาและการประกบแม่พิมพ์จะเป็นสิ่งที่ค่อยๆ หายไป ในขณะเดียวกันชิ้นงานก็ต้องมีคุณภาพภาพที่สูงขึ้นและมีการปรับปรุงประสิทธิภาพการผลิตอย่างต่อเนื่อง

การกระจายตัวทางความร้อนซึ่งเป็นสาเหตุหลักที่ทำให้ความแม่นยำสูงในการขึ้นรูปแม่พิมพ์ด้อยลง เป็นการยากที่จะลดการกระจายตัวจากความร้อนและทำงานตัดที่หนักด้วยสปินเดิลความเร็วสูง เทคโนโลยีการระบายความร้อนของสปินเดิลแบบเดิมที่ใช้กันจะทำการเทน้ำมันหล่อเย็นลงในสปินเดิลที่หมุนอยู่ เพื่อทำให้สปินเดิลเย็นลงโดยตรง อย่างไรก็ตาม สำหรับเทคโนโลยีนี้ เป็นเทคโนโลยีการระบายความร้อนให้กับสปินเดิลแบบใหม่ที่มีโครงสร้างต้นทุนต่ำและประสิทธิภาพการระบายความร้อนสูง โดยการระบายความร้อนเฉพาะส่วนที่จำเป็นอย่างมีประสิทธิภาพ

โครงสร้างและคุณสมบัติ

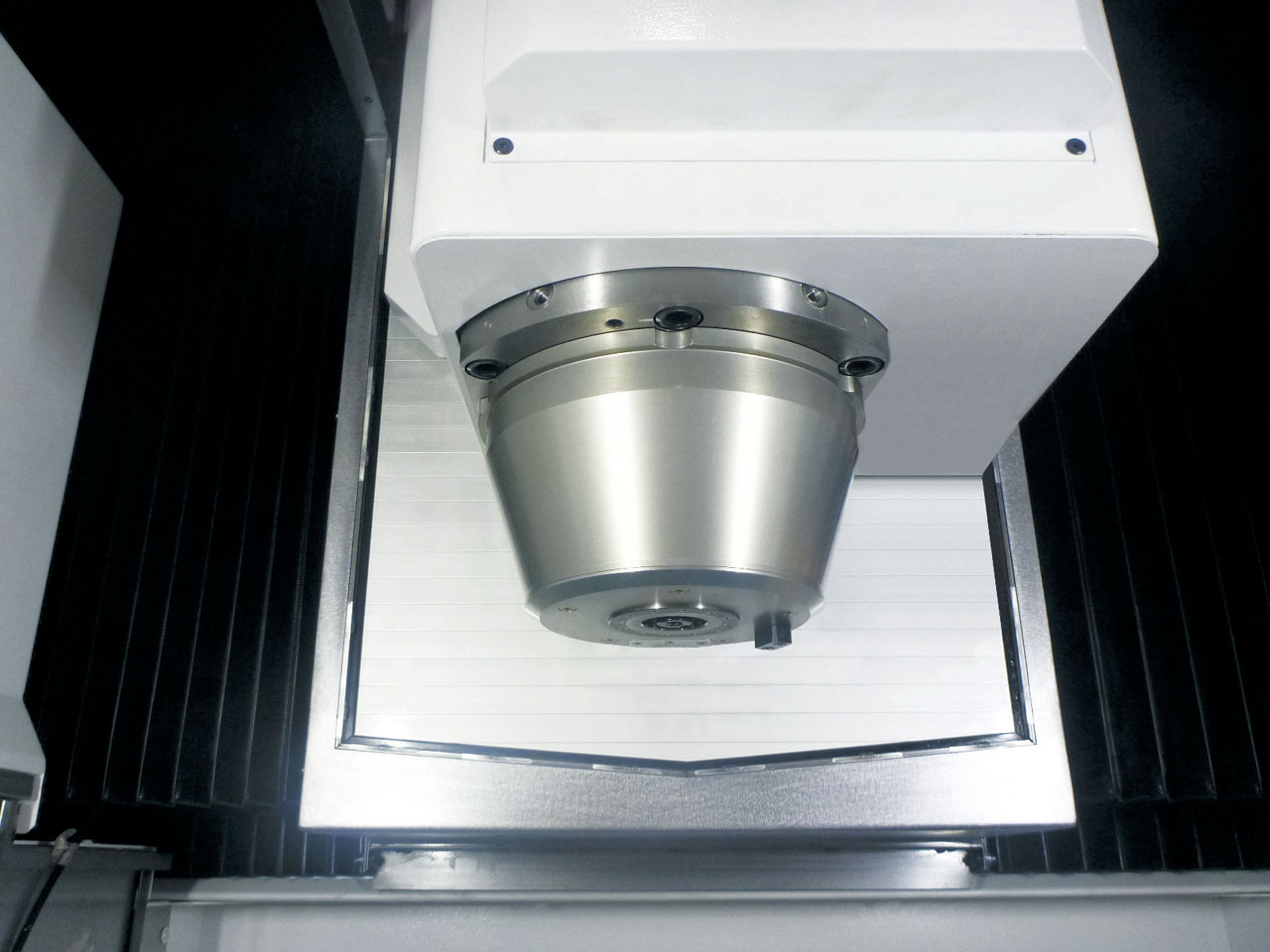

โครงสร้างระบบระบายความร้อนของอุปกรณ์สปินเดิล (ความเร็ว 20,000 รอบต่อนาที) จะระบายความร้อนเฉพาะแบริ่งด้านหน้าที่จำเป็นที่สุดเท่านั้น (รูปที่ 1) อย่างมีประสิทธิภาพ น้ำมันหล่อเย็นจะถูกจ่ายจากระหว่างตลับลูกปืนหน้ากับมอเตอร์ หลังจากระบายความร้อนตลับลูกปืนหน้าแล้ว น้ำมันหล่อลื่นก็จะไหลออกไปทางปลายสปินเดิล

ความแม่นยำสูง

ในการขึ้นรูปแม่พิมพ์ด้วยความแม่นยำสูง จำเป็นต้องลดการกระจายตัวทางความร้อนของสปินเดิลและเครื่องมือให้เหลือน้อยที่สุด ในอุปกรณ์สปินเดิลทั่วไป การระบายความร้อนของสปินเดิลซึ่งเป็นอุปกรณ์หมุนนั้นเป็นเพียงการระบายความร้อนสู่บรรยากาศเท่านั้น และมีผลในการระบายความร้อนได้เพียงเล็กน้อย สปินเดิลและเครื่องมือจะถูกทำให้เย็นลงก่อนการทำงาน (รูปที่ 2 (a)) แต่เมื่อใช้งาน ความร้อนที่เกิดจากตลับลูกปืนและมอเตอร์จะสะสม ส่งผลให้เกิดการขยายตัวทางความร้อน (รูปที่ 2 (d)) จนถึงตอนนี้ เทคนิคการระบายความร้อนสปินเดิลที่มีอยู่ทั้งหมด เพื่อลดการขยายตัวทางความร้อน (รูปที่ 2 (b)) อย่างไรก็ตาม สปินเดิลหลักรองรับด้วยตลับลูกปืน 5 ตัว (ด้านหน้ามีตลับลูกปืน 4 ตัว) ดังนั้น หากบริเวณรอบตลับลูกปืนด้านหน้าเย็นลง การเคลื่อนที่ของปลายเครื่องมือจะลดลงอย่างมีประสิทธิภาพ (รูปที่ 2 (c)) สปินเดิลจะขยายตัวทางความร้อนไปทางด้านหลังโดยไม่คำนึงถึงตำแหน่งปลายเครื่องมือ จึงไม่ส่งผลต่อความแม่นยำสูงในการขึ้นรูปด้วยเครื่องจักร จากแนวคิดนี้ เราได้พัฒนาโครงสร้างการระบายความร้อนด้วยผลการลดการกระจายตัวทางความร้อนได้ในปริมาณมาก ซึ่งจะทำให้บริเวณรอบ ๆ ตลับลูกปืนด้านหน้าที่จำเป็นที่สุดเย็นลงอย่างเห็นได้ชัด

ประสิทธิภาพสูง

เพื่อขจัดการเคลื่อนตัวระหว่างการตกแต่งผิวชิ้นงาน ต้องมีการอุ่นเครื่องอย่างเพียงพอทุกครั้งที่สตาร์ทเครื่องจักร เปลี่ยนเครื่องมือ และเปลี่ยนจำนวนรอบ ซึ่งมักใช้เครื่องมือ 10 ชิ้นขึ้นไปในการผลิตแม่พิมพ์หนึ่งชิ้น การลดประสิทธิภาพการผลิต และการสูญเสียพลังงาน อันเนื่องมาจากการดำเนินการอุ่นเครื่องนั้นมีอย่างมหาศาล ตามเทคโนโลยีของเรา ดังแสดงในรูปที่ 3 เวลาก่อนที่การกระจายตัวทางร้อนจะคงที่นั้นจะลดลงอย่างมาก ดังนั้นการสูญเสียพลังงานเนื่องจากการอุ่นเครื่องจึงสามารถลดลงได้ โดยการใช้ระบบชดเชยการกระจายตัวทางความร้อนเพิ่มเติม การอุ่นเครื่องสามารถลดลงเหลือภายใน 5 นาที

ความสามารถในการขึ้นรูปด้วยเครื่องจักร

เทคโนโลยีการระบายความร้อนสปินเดิลใหม่ถูกใช้เป็นอุปกรณ์ทำงานของแมชชีนนิ่งเซนเตอร์แบบแนวตั้ง “MP-46V” ของเรา สำหรับการผลิตชิ้นส่วนที่มีความแม่นยำสูงและการขึ้นรูปแม่พิมพ์ด้วยเครื่องจักร (รูปที่ 4)

เพื่อปรับปรุงคุณภาพของแม่พิมพ์ ลดต้นทุน และลดระยะเวลารอคอย มีหลายสิ่งที่ต้องทำสำหรับเครื่องแมชชีนนิ่งเซนเตอร์สำหรับการขึ้นรูปแม่พิมพ์ด้วยเครื่องจักร โครงสร้างสปินเดิลใหม่จึงได้รับการพัฒนาขึ้นมา โดยการตรวจสอบการลองผิดลองถูกซ้ำๆ รวมถึงการทดสอบวงจรระบายความร้อน การวิเคราะห์การจ่ายน้ำหล่อเย็นขณะที่สปินเดิลทำงานด้วยความเร็วสูง ที่เชื่อถือได้ เราได้ทำการทดลอง ผลิต และตรวจสอบ ในที่สุดก็สามารถสร้างสปินเดิลพร้อมประสิทธิภาพการระบายความร้อนสูง ซึ่งประสิทธิภาพของ “MP-46V” ที่ติดตั้งเทคโนโลยีการระบายความร้อนของสปินเดิลใหม่นั้นดีขึ้นอย่างมาก เมื่อเทียบกับรุ่นทั่วไปในทุกรายการ (รูปที่ 5) “MP-46V” สำหรับการขึ้นรูปชิ้นงานและแม่พิมพ์ที่มีความแม่นยำสูง ซึ่งที่ติดตั้งเทคโนโลยีระบายความร้อนสปินเดิลใหม่ ได้ออกวางตลาดแล้ว และลูกค้าให้การตอบรับเป็นอย่างดี

Article by: Okuma Techno (Thailand) Ltd. & MEGA Tech