ในช่วงไม่กี่ปีที่ผ่านมา ชิ้นส่วนแม่พิมพ์มีแนวโน้มที่จะต้องการความเที่ยงตรงสูงขึ้นและมีรูปทรงที่ซับซ้อนมากขึ้น ซึ่งทำให้กระบวนการตัดเฉือนเพื่อผลิตแม่พิมพ์นั้นมีความซับซ้อนยุ่งยากมากขึ้นตามไปด้วย โดยเฉพาะอย่างยิ่ง ความต้องการในการที่จะลดเวลาที่ใช้ในการขัดผิวงานด้วยแรงงานคนนั้น ทำให้จำเป็นต้องหาวิธีการ ตัดเฉือน ที่ให้คุณภาพผิวงานสูงขึ้น

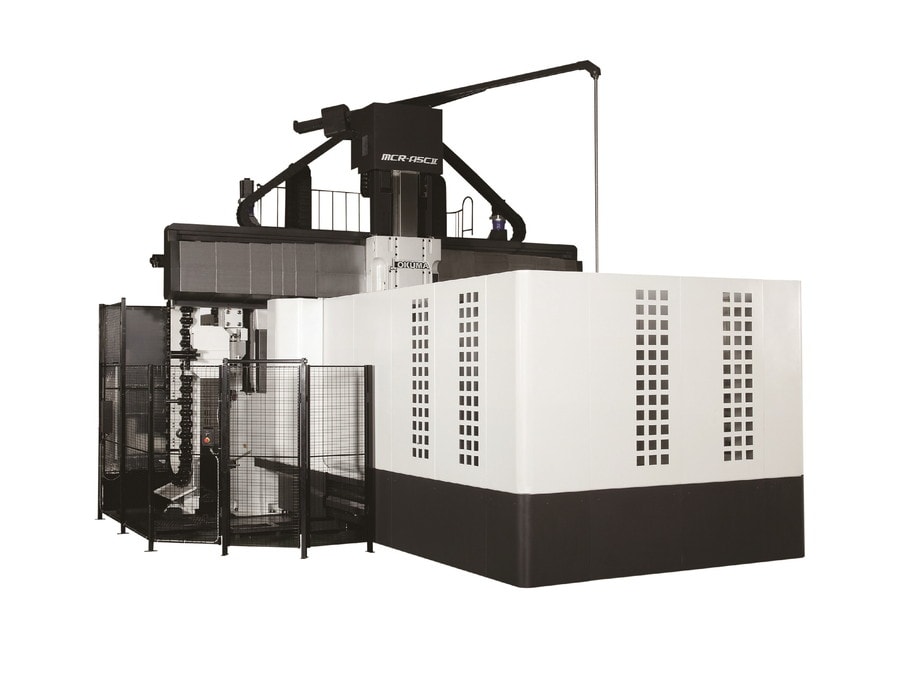

อย่างไรก็ตาม ทุกองค์ประกอบของการผลิต ไม่ว่าจะเป็นเครื่องจักร การควบคุม ลักษณะการตัดเฉือน โปรแกรมตัดเฉือน เป็นต้น ล้วนแล้วแต่มีความสำคัญด้วยกันทั้งสิ้น สำหรับ OKUMA เอง นอกจากจะพัฒนา เครื่องจักร แล้ว บริษัทยังมีการพัฒนาในส่วนของส่วนประกอบทางไฟฟ้า อุปกรณ์ควบคุม และซอฟต์แวร์ด้วยเช่นกัน ซึ่งการพัฒนาเทคโนโลยีในสาขาต่างๆ นั้นมีเป้าหมายเพื่อที่จะตอบโจทย์ความท้าทายของงานตัดเฉือนความเที่ยงตรงสูงและคุณภาพสูง

บริษัทได้มีการพัฒนากระบวนการตัดเฉือนเพื่อให้ได้คุณภาพผิวงานสูงขึ้น โดยการคิดค้นฟังก์ชั่นแก้ไขรูปทรงและฟังก์ชั่นควบคุมและปรับรูปทรง เพื่อแก้ปัญหาผิวงานคุณภาพต่ำที่มีสาเหตุมาจากการเขียนโปรแกรมตัดเฉือน ซึ่งเป็นที่มาของ “Hyper-Surface” เทคโนโลยีใหม่ที่ถูกพัฒนาขึ้นโดยเฉพาะ เพื่อผิวงานที่มีคุณภาพสูงขึ้น

1. ฟังก์ชั่นที่พัฒนาขึ้นใหม่ล่าสุดสำหรับชดเชยโปรแกรมตัดเฉือน

ฟังก์ชั่นนี้จะทำหน้าที่วิเคราะห์และแก้ไขโปรแกรมตัดเฉือนผ่านทาง NC โดยมีฟังก์ชั่นใหม่ที่ช่วยให้ได้คุณภาพผิวงานระดับสูงได้แบบง่ายๆ

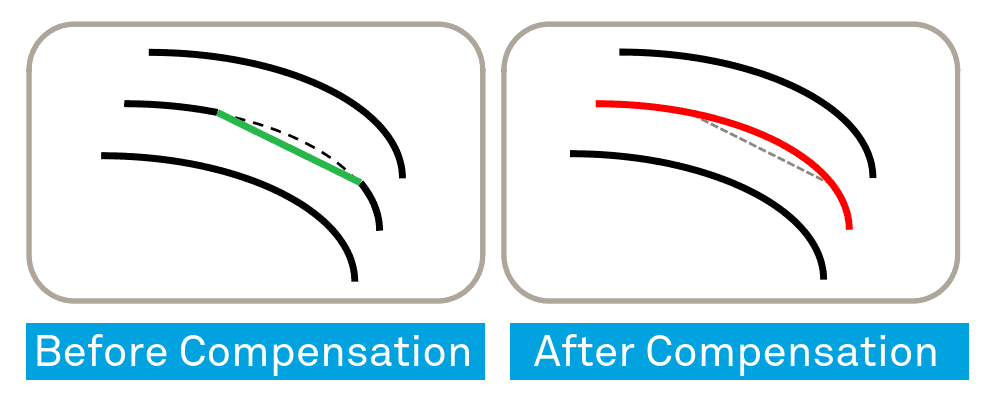

1.1 ฟังก์ชั่นชดเชยแนวการตัด

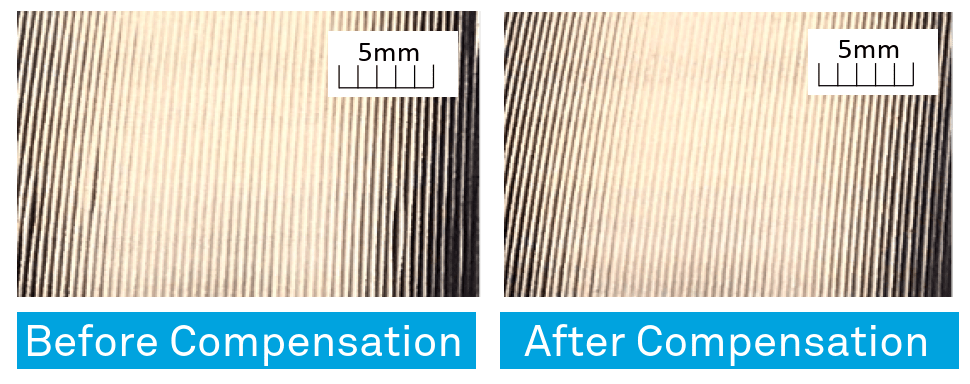

ประเมินรูปทรงดั้งเดิมจากจุดคำสั่งของทางเดินข้างเคียง ชดเชยขั้นของทางเดิน และสร้างผิวงานที่สม่ำเสมอ

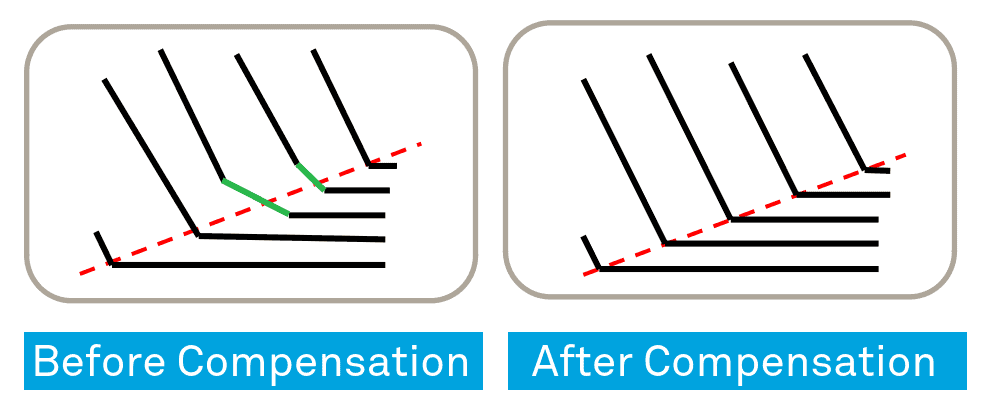

1.2 ฟังก์ชั่นชดเชยขอบงาน

ประเมินขอบงานดั้งเดิมจากจุดคำสั่งของขอบงาน ชดเชยขอบงานให้สม่ำเสมอ

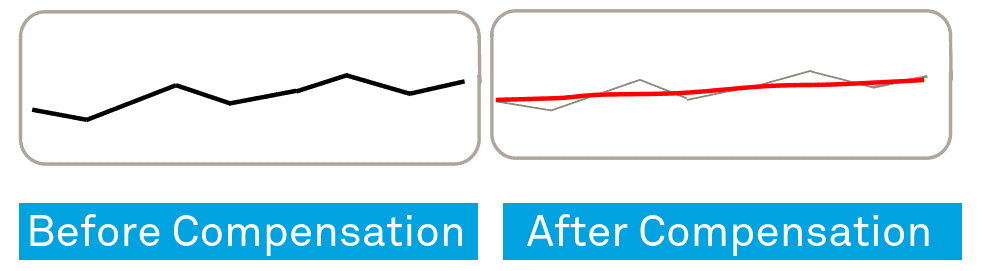

1.3 ฟังก์ชั่นปรับเรียบตำแหน่งคำสั่ง

ตรวจหาและชดเชยตำแหน่งคำสั่งขนาดเล็ก ปรับความผันผวนของค่าความเร็วให้เรียบขึ้นและเสถียรขึ้น รวมทั้งยังช่วยลดระยะเวลาการตัดเฉือน

2. ฟังก์ชั่นที่ผลลัพธ์และสรุป

“Hyper-Surface” มีความสามารถในการชดเชยโปรแกรมตัดเฉือน แก้ปัญหาแนวการตัด และให้ผิวงานคุณภาพสูง กระบวนการตัดเฉือนมีคุณภาพผิวงานสูงขึ้น รวมทั้งยังช่วยลดต้นทุนการแก้ไขโปรแกรม CAD/CAM และชั่วโมงทำงานที่ใช้ บริษัทของเรามุ่งมั่นที่จะตอบโจทย์ความต้องการของลูกค้าอย่างต่อเนื่องด้วยการพัฒนาเทคโนโลยีในสาขาต่างๆ

Article by: OKUMA Techno (Thailand) Co., Ltd.

Reference: https://www.okumathai.com/