ปัจจุบันเทคโนโลยีการขึ้นรูปโลหะมีการพัฒนาและเปลี่ยนแปลงไปอย่างรวมเร็วตามความต้องการความแม่นยำสูงและคุณภาพชิ้นงานที่ดีกว่า ซึ่งเครื่อง EDM ถือเป็นเครื่องจักรชนิดหนึ่งที่ได้รับความนิยมเพราะสามารถตอบโจทย์ความต้องการในอุตสาหกรรมได้เป็นอย่างดี

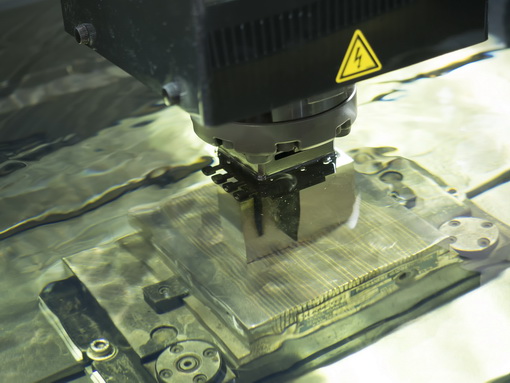

EDM หรือ Electrical Discharge Machine คือเครื่องกัดชิ้นงานโลหะ โดยอาศัยการปล่อยกระแสไฟฟ้าที่มีความต่างศักย์สูงเข้าสู่ Electrode ซึ่งเป็นวัสดุนำไฟฟ้าสูง เช่น ทองแดงหรือ แกรไฟต์ เพื่อให้เกิดการ Spark บนตัวชิ้นงาน ทำให้ชิ้นงานเกิดความร้อนและเกิดการกัดกร่อนบนเนื้องานให้ได้รูปร่างตามที่ออกแบบในระบบ CAD/CAM ซึ่งงานที่นิยมนำมาใช้กับเครื่อง EDM จะเป็นงานเฉพาะทางที่มีความซับซ้อนสูง ผลิตได้ยาก หรืองานที่ไม่สามารถผลิตหรือตัดเฉือนด้วยเครื่องกัดกลึง CNC ได้ หรือชิ้นงานที่ผลิตด้วยวัสดุเฉพาะทางหรือผ่านการชุบแข็งมาแล้ว งานผลิตแม่พิมพ์ งานต้นแบบ เป็นต้น นอกจากนี้ในระยะหลังผู้ประกอบการเริ่มเห็นประโยชน์จากการนำเครื่อง EDM มาใช้เป็นส่วนหนึ่งในกระบวนการผลิตเพื่อผลิตชิ้นงานโดยตรงมากขึ้นเนื่องจากความแม่นยำในการทำงานที่สูงกว่า เพราะในประกอบการผลิตไม่มีเศษชิ้นงานเข้ามารบกวนในระหว่างการผลิต อีกทั้งยังให้คุณภาพผลิตชิ้นงานที่สวยกว่า จึงทำให้ในหลายๆอุตสาหกรรมโดยเฉพาะอุตสาหกรรมเครื่องบิน และอุตสาหกรรมไอทีให้ความสนใจและนำมาเป็นส่วนหนึ่งในการผลิตมากขึ้น

เครื่องจักรชนิดนี้ถือว่าเป็นเครื่องจักรที่ได้รับความนิยมและเป็นที่ต้องการมากในกลุ่มอุตสาหกรรม โดยเฉพาะกลุ่มธุรกิจผู้ผลิตชิ้นส่วนยานยนต์ที่ทำรายได้เป็นอันดับต้นๆของประเทศและมีการแข่งขันสูง ทำให้ผู้ประกอบการจำนวนมากเริ่มให้ความสำคัญกับการยกระดับศักยภาพในการผลิตเพื่อให้ได้ชิ้นงานที่มีคุณภาพจากเครื่องจักรคุณภาพสูง ดังนั้น มิตซูบิชิ อีเล็คทริค จึงได้นำเสนอผลิตภัณฑ์ NC EDM Systems EA-PS Series เพื่อตอบโจทย์การพัฒนาประสิทธิภาพทางอุตสาหกรรมให้กับลูกค้า

เครื่อง EA-PS เป็นเครื่อง NC EDM System ในระดับ High –Accuracy ที่สามารถทำผิวชิ้นงานได้เรียบถึงระดับ Ra 0.05 um ด้วยความแม่นยำที่ ± 3 ไมครอน อีกทั้งยังมี function ผิวงานใบบัว (Lotus Leaf Texture) ถ้าใช้งานควบคู่กับ Electrode ทองแดง รวมถึงระบบ IDPM หรือ Integrated Discharge Power Master ที่เป็นระบบช่วยควบคุมการสปาร์คและลดการสึกหรอในตัว Graphite Electrode ทำให้กัดชิ้นงานได้แม่นยำขึ้น และระบบ SS Jump ที่ได้ปรับปรุงใหม่ช่วยให้เครื่องสามารถทำงานได้เร็วขึ้น 40%

และนอกเหนือไปกว่านั้นทางมิตซูบิชิยังได้นำเสนออีกหนึ่งผลิตภัณฑ์ EDM Series ที่เป็นตัว Popular Model ของมิตซูบิชิ อีเล็คทริค ด้วยการใช้งานที่เรียบง่าย มีจุดเด่นในเรื่องของประสิทธิภาพและความคุ้มค่า เครื่อง NC EDM System EA-S Series สามารถกัดชิ้นงานที่เป็นโลหะแล้วยังสามารถกัดวัสดุพิเศษประเภท Tungsten Carbide พร้อม IDPM ซึ่งเป็น Standard Function เป็นเครื่องในระดับ High Productivity Machine ที่เหมาะกับงานประเภท Smartphone, Plastic Mold และ Automation การใช้งานสะดวกเพียงปลายนิ้วสัมผัสบาหน้าจอ Touch Screen 15 นิ้วสามารถเปิด Tank ได้ 3 ด้านเพื่อสะดวกในการวางชิ้นงาน ซึ่งทั้ง 2 รุ่นนี้สามารถรอบรับการทำงานรวมกับระบบออโตเมชั่นได้อย่างมีประสิทธิภาพ

การพัฒนาเครื่อง EDM ยังคงมีอยู่อย่างต่อเนื่องตามการเปลี่ยนแปลงทางด้านอุตสาหกรรม และความต้องการทางการผลิตที่ต้องการประสิทธิภาพที่สูงขึ้น โดยเฉพาะอย่างยิ่งการนำเครื่อง EDM เข้ามามีบทบาทในส่วนสายการผลิตในอุตสาหกรรม ที่ต้องการการผลิตชิ้นส่วนที่มีความซับซ้อนมากกว่า แม่นยำมากกว่า และแน่นอนความเครื่องจักรเหล่านี้จะต้องสามารถประสานการทำงานและควบคุมการผลิตได้อย่างอัตโนมัติตามแนวทางการผลิตวนระดับอุตสาหกรรม 4.0 ต่อไป