อุตสาหกรรมยานยนต์ของประเทศไทยเติบโตอย่างมากในช่วง 55 ปีที่ผ่านมา มีสัดส่วนร้อยละ 10 ของ GDP ของประเทศ โดยมียอดขายรถยนต์มากกว่า 759,000 คันในปี 2021 ความสำเร็จนี้ทำให้ประเทศเป็นผู้ผลิตยานยนต์รายใหญ่ที่สุดในสมาคมประชาชาติแห่งเอเชียตะวันออกเฉียงใต้ (อาเซียน) และเป็นผู้ผลิตรถยนต์รายใหญ่อันดับ 10 ของโลก ในฐานะศูนย์กลางยานยนต์แห่งเอเชีย ประเทศไทยวางตำแหน่งตัวเองอย่างต่อเนื่องในฐานะผู้ผลิตยานยนต์แห่งอนาคตด้วยนโยบายการผลิตที่มีมูลค่าเพิ่มสูงขึ้นและการปกป้องสิ่งแวดล้อม

จากกระแสลดคาร์บอนที่กำลังมาแรงในขณะนี้ ส่งผลให้การลงทุนผลิตยานยนต์ไฟฟ้า (EV) เพิ่มขึ้นทั่วโลก ทำให้ผู้ผลิตต้องการเพิ่มประสิทธิภาพของการผลิตชิ้นส่วนหลักของยานยนต์ไฟฟ้า เช่น มอเตอร์ และ อินเวอร์เตอร์ ส่งผลให้ความคาดหวังและความต้องการเครื่องเชื่อมโลหะ FSW (การเชื่อมแบบกวนด้วยแรงเสียดทาน) ซึ่งเป็นเทคโนโลยีที่จะช่วยเพิ่มประสิทธิภาพให้กระบวนการเชื่อมโลหะ เพิ่มขึ้นตามไปด้วย

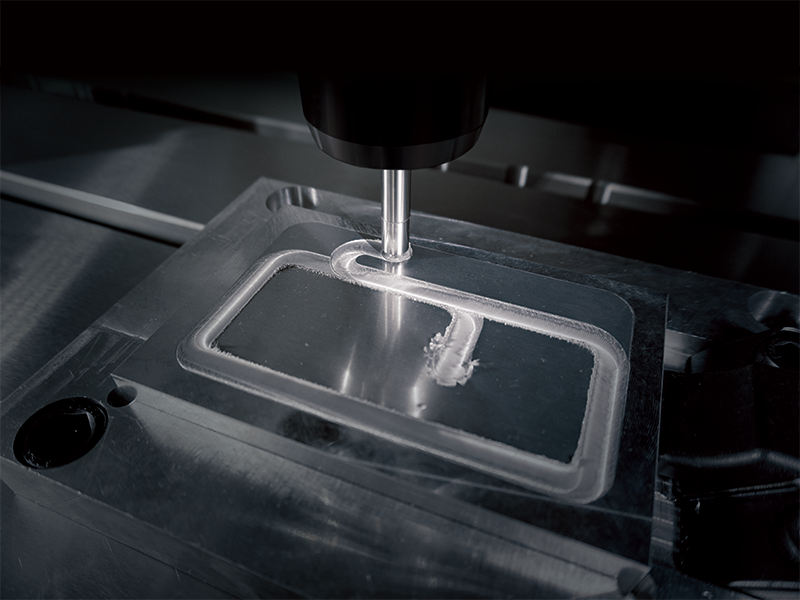

ในปี 2557 Mazak เปิดตัวเครื่องเชื่อมโลหะไฮบริดมัลติทาสกิ้งเป็นครั้งแรกในอุตสาหกรรมเครื่องเชื่อมโลหะ ซึ่งรวมฟังก์ชันการเชื่อมแบบกวนด้วยแรงเสียดทานและการตัดเฉือนไว้ในเครื่องเดียวกัน Mazak มุ่งมั่นพัฒนาเทคโนโลยีผสมนี้ตลอด 10 ปีที่ผ่านมา ในช่วงเวลาดังกล่าว Mazak ได้พัฒนาและนำเสนอเครื่องเชื่อม FSW ให้กับอุตสาหกรรมต่าง ๆ ซึ่งส่วนใหญ่เป็นอุตสาหกรรมยานยนต์และเซมิคอนดักเตอร์ ทำให้ Mazak ได้สะสมประสบการณ์และความสำเร็จเรื่อยมา เพื่อตอบสนองความต้องการเครื่องเชื่อม FSW ที่กำลังเติบโตอย่างต่อเนื่อง ซึ่งรวมถึงอุตสาหกรรมรถยนต์ไฟฟ้าด้วย Mazak จึงได้พัฒนาเครื่องเชื่อมโลหะแบบกวนด้วยแรงเสียดทาน รุ่น FSW-460V จากพื้นฐานความรู้ความเชี่ยวชาญที่สั่งสมตลอดระยะเวลาที่ผ่านมา

FSW-460V เป็นเครื่องเชื่อมโลหะแบบกวนด้วยแรงเสียดทาน ที่ทำงานเร็วและให้คุณภาพงานยอดเยี่ยม ซึ่งนอกจากสปินเดิลที่แข็งแกร่งเพื่อทำงานที่ความเร็วรอบสูงที่พัฒนาล่าสุดแล้ว ยังมีทูลรูปทรงพิเศษ ที่มาพร้อมระบบควบคุมแรงกดและการตรวจจับรอยแตกบิ่นของทูล ทั้งหมดนี้ทำให้ได้กระบวนการเชื่อมแบบกวนด้วยแรงเสียดทานที่รวดเร็วและมีคุณภาพสูง นอกจากนี้ ระบบเปลี่ยนทูลอัตโนมัติ ยังช่วยให้กระบวนการเชื่อมโลหะต่อเนื่อง ส่งผลดีไปถึงการเพิ่มผลผลิตและประสิทธิภาพของชิ้นส่วนยานยนต์ไฟฟ้าที่สำคัญ ซึ่งรวมถึงเสื้อมอเตอร์และอุปกรณ์ระบายความร้อนให้อินเวอร์เตอร์ด้วย

เพื่อให้บรรลุความฝันในการเป็นศูนย์กลาง EV เชื่อว่าประเทศไทยอยู่ในตำแหน่งที่ดีในการรับมือกับความท้าทายเหล่านี้และบรรลุพันธกรณีด้านรถยนต์ไฟฟ้า หากประเทศไทยให้ความสำคัญกับความท้าทายที่ระบุและพัฒนาโซลูชันที่ตรงเป้าหมาย จะต้องปฏิบัติตามเกณฑ์เหล่านี้เพื่อให้ประเทศไทยบรรลุความฝันที่จะกลายเป็นแหล่งผลิตรถยนต์ไฟฟ้าระดับโลก โดยเฉพาะอย่างยิ่งในภูมิภาคเอเชียตะวันออกเฉียงใต้และประเทศเกิดใหม่

Article by: MEGA Tech & Mazak (Thailand) Co., Ltd.