มากกว่า 70 ปีที่ Takamaz นำเสนอ เครื่องจักร หลากหลายประเภทตั้งแต่ขนาดหัวจับงาน 3 ถึง 10 นิ้ว เราทุ่มเทเพื่อนำเสนอโซลูชั่นการตัดแบบร่วมสมัยสำหรับความท้าทายที่ลูกค้าของเราเผชิญอยู่ทั้งในปัจจุบันและในอนาคต เราเชี่ยวชาญในระบบอัตโนมัติเต็มรูปแบบที่อำนวยความสะดวกในการผลิตจำนวนมาก (Mass Production) ของชิ้นส่วนกล่าวคือใช้ใน อุตสาหกรรมยานยนต์ โดยแต่ละชิ้นได้รับการปรับแต่งตามความต้องการเฉพาะของผู้ใช้

การใช้วิธีการที่เป็นส่วนตัวมากกว่ารูปแบบ ‘ทั้งหมดในแบบเดียว’ (‘One Size Fits All’) ทำให้เราแตกต่างจากคู่แข่งและทำให้เราได้รับความไว้วางใจจากหลายหลายลูกค้าที่แตกต่างกันในช่วงหลายปีที่ผ่านมาภายใต้ Concept ว่า “Infinite Possibility For Customization”

นั่นเป็นสาเหตุที่เรามี 25 รุ่นที่แตกต่างกันในรายการหลักของเรามีมากกว่า 40 รายการให้เลือกและมีตัวเลือกการปรับแต่งพิเศษที่หาตัวจับยากเพื่อให้มั่นใจว่าเครื่องที่คุณสั่งซื้อตรงกับวัตถุประสงค์และดีกว่าเครื่องอื่นๆ

ณ ปัจจุบัน เป็นที่ทราบดีว่าในธุรกิจการผลิตขึ้นรูปโลหะโดยเฉพาะชิ้นส่วนยานยนต์ มีการแข่งขันกันอย่างมากในเรื่องของราคาและคุณภาพของชิ้นงาน ดังนี้สิ่งที่จะตอบโจทย์ของผู้ผลิตจึงหนีไม่พ้นเรื่องการลดต้นทุนหรือการควบคุมต้นทุน รวมทั้งคุณภาพของขิ้นงานที่จะต้องให้ความไว้วางใจจากลูกค้าของผู้ผลิตเอง

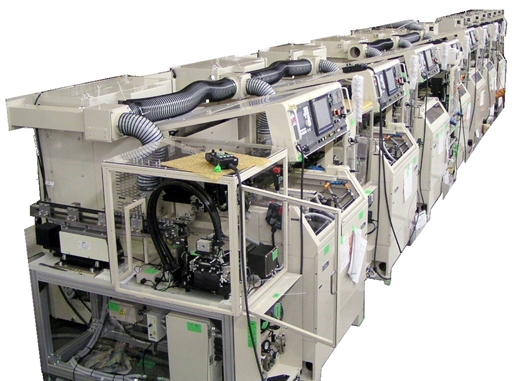

ตั้งแต่ปี 2007 ยอดการสั่งซื้อ เครื่องจักรรุ่น XW-30 เพิ่มขึ้นอย่างต่อเนื่องในทุกปีแม้ในช่วงวิกฤตการเงินโลก เหตุผลนี้คือโครงสร้างที่กะทัดรัดความเร็วสูงและความแม่นยำของ XW-30 รวมถึงอุปกรณ์ป้อนงาน (Loader) ที่สร้างขึ้นทั้งหมดรวมอยู่ในราคาที่ไม่สูงมาก

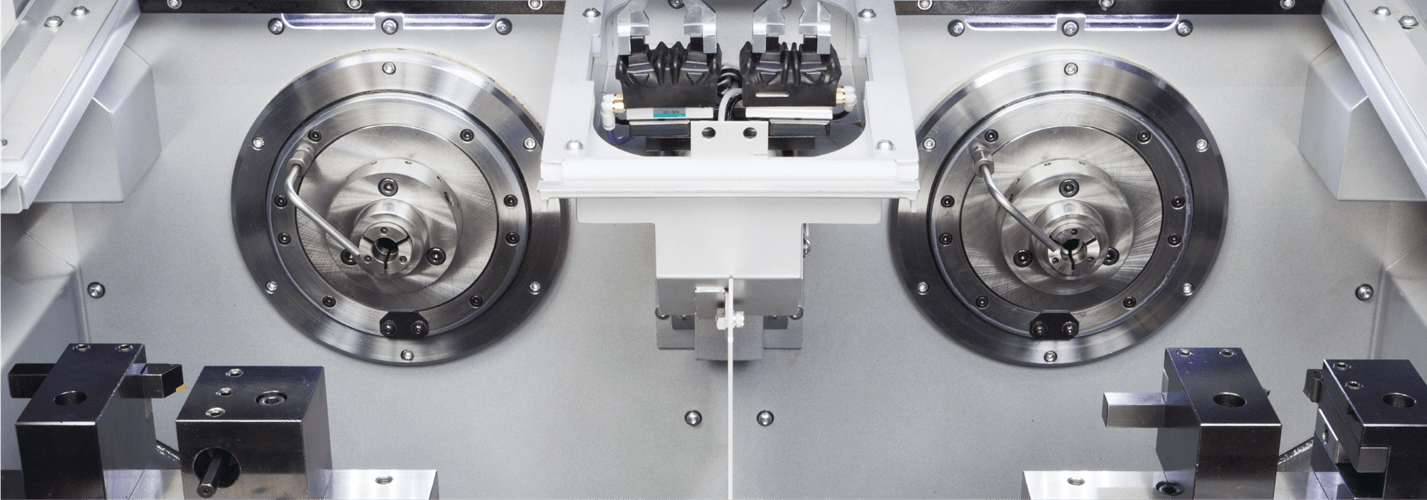

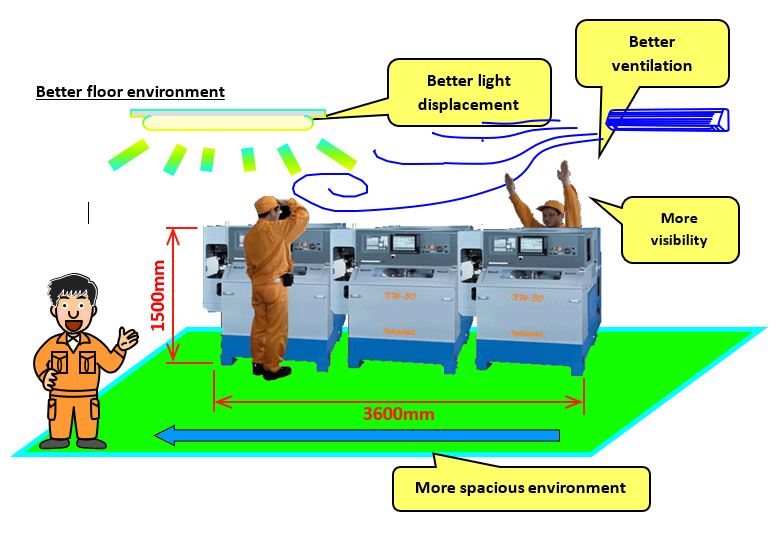

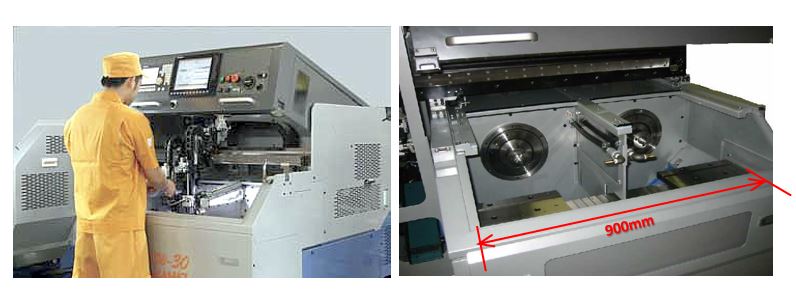

XW-30 เป็นเครื่อง 2 หัว (2-Spindle) ขนาดกะทัดรัดที่สุดของเราที่เคยมีมาซึ่งมีความกว้างเพียง 1 เมตร และความสูง 1.5 เมตร โดยพื้นฐานแล้วเป็นการออกแบบโดยนำมารวมกันของเครื่อง Takamaz รุ่น USL-480 2 เครื่อง และการออกแบบช่วยปรับปรุงเรื่องการมองเห็นและการระบายอากาศรอบตัวเครื่อง รวมถึงการออกแบบเพื่อเข้าถึงการบำรุงรักษาด้านหน้าและด้านหลังโดยไม่จำเป็นต้องเข้าถึงเครื่องจากด้านข้าง ในส่วนของการเตรียมงาน การออกแบบให้เปิดฝาครอบตำแหน่งควบคุมช่วยให้คุณเข้าถึงพื้นที่ที่กว้างถึง 900 มม. ทำให้การเปลี่ยนแปลงเครื่องมือและการทำงานเป็นเรื่องง่าย

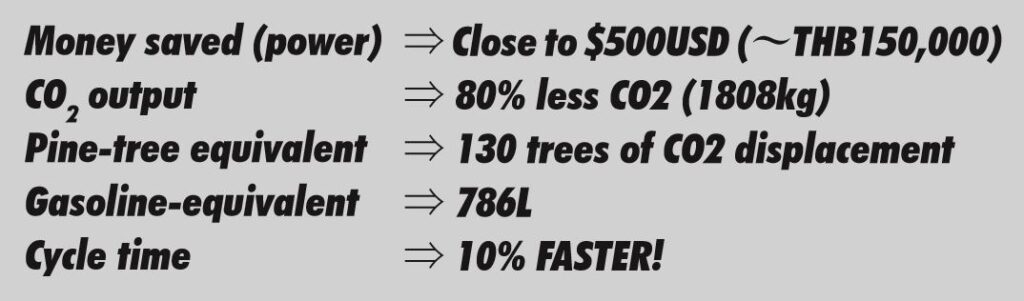

นอกจากประสิทธิภาพการออกแบบอันน่าทึ่งของ XW-30 ที่ช่วยประหยัดพื้นที่ของผู้ใช้แล้ว การออกแบบเพื่อเพื่อลดปริมาณการกินกระแสไฟฟ้าเวลาทำงานก็ได้มีการพัฒนาอีกด้วย และด้วยเหตุนี้ผู้ใช้สามารถประหยัดค่าใช้จ่ายนั่นก็หมายถึงการลดต้นทุนอีกด้วย!

มีการเปลี่ยนแปลงหลายอย่างในการออกแบบของ XW-30 เพื่อเพิ่มประสิทธิภาพของพื้นที่บนพื้น ในขณะที่รักษาการเข้าถึงการบำรุงรักษาได้ง่ายจากด้านหน้าของเครื่องเพื่อเปลี่ยนการใช้งานของเครื่องจักรได้อย่างง่ายดาย เราได้กำจัดพื้นที่ไม่จำเป็นและเพิ่มความจำเป็นในการเข้าถึงฝาครอบด้านข้าง

ฝาครอบขนาดใหญ่หนึ่งช่องเปิดขึ้นเพื่อเข้าถึงด้านหน้าของเครื่องช่วยเพิ่มความสะดวกและปลอดภัย การยกฝาครอบนี้เป็นการเปิดพื้นที่กว้างเพื่อให้สามารถเข้าถึงส่วนประกอบกลไกที่สำคัญที่สุดของเครื่องได้ง่ายจากบนลงล่าง

เนื่องจากตัวโหลดงานอัตโนมัติ (Loader) ใช้แกน Z ของ Spindle เคลื่อนที่มาเพื่อรับงาน ดังนั้นการตัวโหลดงานแบบ 2 แกนนั้นเพียงพอสำหรับงานซึ่งหมายถึงชิ้นส่วนทางกลน้อยลง 30% ทำให้ใช้พลังงานน้อยลงและมีต้นทุนที่ต่ำกว่า

Eco ของเครื่อง【การใช้พลังงานต่ำ】ด้วยการใช้วัสดุน้ำหนักเบาที่ช่วยลดแรงเสียดทานและมอเตอร์ในตัว XW-30 ใช้พลังงานน้อยกว่ารุ่นก่อน การตัดชุดการทำงานไฮดรอลิกออก ก็ทำให้ช่วยลดการใช้พลังงานอย่างมาก จากการบันทึก XW-30 สามารถลดการใช้พลังงานลงได้ถึง 74% ในระหว่างทำงานเมื่อเทียบกับรุ่น 1 spindle ของ Takamaz ใน X series

Cycle time reduction

ลูกค้าผู้ผลิตชิ้นส่วนรถยนต์ของเราต้องการเครื่องจักรที่สามารถลดค่าใช้จ่ายในการทำงานได้ถึง 30%

โดยปกติการโหลดงานและการเคลื่นที่ของแกนมีด “เวลาเตรียม” หรือตามที่เเรียกว่า “เวลาที่เสียไป” ที่ Takamaz เราจึงมีเป้าหมายที่จะลดเวลาที่เสียไปของผู้ใช้ของเราให้มากที่สุดเท่าที่จะทำได้

เพื่อตอบสนองลูกค้าของเราโดยตรงเราได้สร้างเครื่องจักรที่สามารถทำได้โดยลดเวลาการทำงานลงอย่างมากภายใต้ concept เครื่องความเร็วสูง, ขนาดกะทัดรัด และความแม่นยำสูง→ด้วยการพัฒนาตัวป้อนงาน (High speed loader) Takamaz ที่ความเร็วสูงเพื่อให้ได้ความเร็วในการโหลดอย่างไม่น่าเชื่อที่ 2 วินาทีเราเพิ่มความเร็วในการเคลื่อนที่ของ loader จาก 80m / s เป็น 100 ~ 150m/s (เร็วขึ้นมากกว่า 15%) ด้วยการใช้ gripper แบบ W ที่ได้รับสิทธิบัตรของเราก็สามารถลดจุดเคลื่อนที่ได้

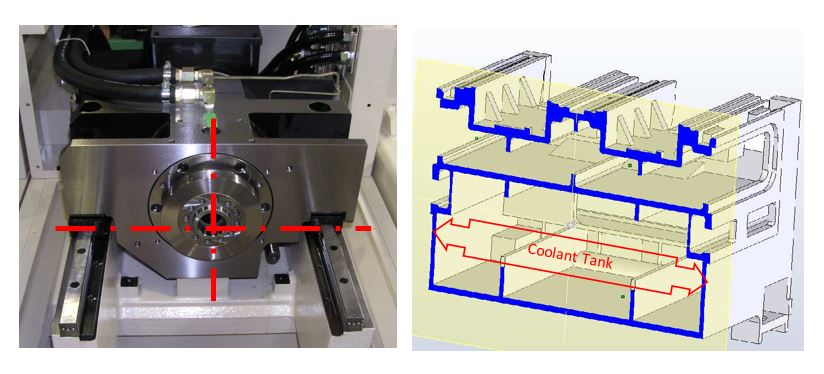

ในส่วนของเรื่องความแม่นยำ XW-30 มีคุณสมบัติใหม่มากมายที่ให้ความเร็วและความแม่นยำสูง การใช้โครงสร้างของเครื่องที่ป้องกันการบิดเบือนความร้อนซึ่งจะสามารถเก็บระดับของสไลด์และแกนหมุน (spindle) ให้อยู่บนระนาบเดียวกันเราสามารถลดผลกระทบของการบิดเบือนความร้อนบนแกนหมุนได้อย่างมาก

อีกทั้ง ด้วยการวางระบบหล่อเย็นของแกนหมุน (Spindle) ในตัวเครื่อง อุณหภูมิของเครื่องจะถูกเก็บไว้ที่อุณหภูมิเดียวกัน นอกจากนี้ยังทำหน้าที่สองวัตถุประสงค์ในการลดผลกระทบของการสั่นสะเทือนในระหว่างการตัดงานได้อีกด้วย

รวมถึง จากการทดสอบความเสถียรภาพของขนาดงานที่ตัด ที่การใช้งานที่อุณหภูมิโชว์รูมในโรงงาน Takamaz ที่ 24~ 25 ° และสารหล่อเย็นชนิดน้ำ (emulsion type 7%) เริ่มตัดต่อเนื่องที่เวลา 9:00 น. ทำให้ได้ค่าความเปลี่ยนแปลงของความโตชิ้นงานแค่ 4μm ซึ่งเป็นค่าที่น้อยมาก ดังนั้นเครื่อง XW-30 นี้จึงเป็นเครื่องกลึงที่มีความเสถียรภาพและะเป็นตัวเลือกที่ยอดเยี่ยมสำหรับการผลิตในปริมาณมากและมีความแม่นยำสูง

จากคุณสมบัติที่กล่าวมาของ XW-30 นี้ ทำให้เป็นเครื่องที่ได้รับรางวัลในด้านการประหยัดพลังงานจาก Japan Machinery Federation (JMF) Chairman’s Award และรางวัล Superior Product Prize Winning จากสมาคมวิศวกรเครื่องกลของญี่ปุ่น (The Japan Society of Mechanical Engineers (JSME)) ในปี 2010 อีกด้วย

Article by: Takamatsu Machinery Co., Ltd.