หนึ่งในกลไกขับเคลื่อนการทำงานของเครื่องจักรให้มีประสิทธิภาพตอบโจทย์ความต้องการของระบบการผลิตนั้น คือ สปินเดิล โดยผู้ผลิตเครื่องจักรล้วนให้ความสำคัญ ด้วยการพัฒนานวัตกรรมของสปินเดิลที่สามารถเพิ่มประสิทธิภาพการผลิตด้วยเทคโนโลยีขั้นสูงอย่างน่าสนใจ

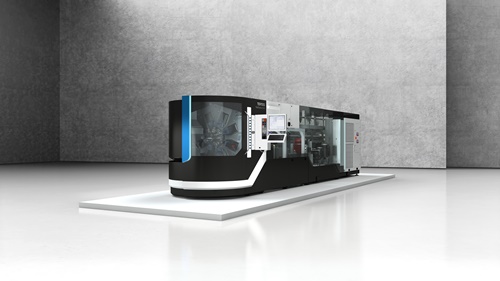

เครื่องกลึง มัลติสปินเดิลรุ่น MultiSwiss คือคำตอบที่เปรียบเสมือนคำมั่นสัญญาจาก Tornos: เราพร้อมจะช่วยให้ งานกลึง ของคุณต่อเนื่องไร้ปัญหา เครื่องกลึง รุ่น MultiSwiss เป็น เครื่องกลึง แบบมัลติสปินเดิลที่พร้อมตอบโจทย์สำหรับทุกอุตสาหกรรม และขับเคลื่อนประสิทธิภาพการผลิตของบริษัทผู้ผลิตให้สูงขึ้นอีกขั้น

เครื่องกลึง รุ่น MultiSwiss โดดเด่นด้วยความง่ายในการใช้งาน ความเที่ยงตรง ขนาดที่เล็ก รวมถึงความเชื่อถือได้และความประหยัดที่เหนือกว่าสำหรับการผลิตที่ต้องการประสิทธิภาพสูง MultiSwiss ได้รับการออกแบบโดยเน้นความสะดวกในการใช้งาน อีกทั้ง การติดตั้งเครื่องมือสามารถทำได้ง่ายเหมือน เครื่องกลึง แบบหนึ่งสปินเดิล และให้ประสิทธิภาพการผลิตสูงกว่าเครื่องจักรแบบหนึ่งสปินเดิลรุ่นอื่นๆ ในตลาดถึงห้าเท่า นอกจากนี้ ยังมีความยืดหยุ่นสูง ทำให้ผู้ผลิตสามารถตอบสนองต่องานเร่งด่วนได้อย่างรวดเร็ว

เครื่องกลึง MultiSwiss มีเส้นผ่านศูนย์กลางให้เลือกสามขนาด ได้แก่ 16 มม. และ 32 มม. (รุ่นหกสปินเดิล) และ 26 มม. (รุ่นแปดสปินเดิล) โดยใช้เทคโนโลยีทอร์กมอเตอร์ในการอินเด็กซ์แมกกาซีนของชุดสปินเดิล พร้อมด้วยการทำงานที่รวดเร็วเป็นพิเศษที่ช่วยให้ได้รอบระยะเวลาในการผลิตใกล้เคียงกับการใช้ เครื่องจักรมัลติสปินเดิล แบบควบคุมด้วยลูกเบี้ยว ส่งผลให้ลูกค้าได้รับประสิทธิภาพการผลิตที่สูงยิ่งขึ้น

ในแง่ของความยืดหยุ่น MultiSwiss ช่วยให้บริษัทผู้ผลิตสามารถทำงานทุกประเภทได้อย่างมีประสิทธิภาพ เนื่องจากมีระบบควบคุมความเร็วของแต่ละสปินเดิลแบบอิสระ ระบบ Plug-and-Run สำหรับอุปกรณ์ต่างๆ การทำงานในแกน Y (อุปกรณ์ติดตั้งเสริม) พร้อมระบบหล่อเย็นภายในของชุดป้อม มีดตัดเฉือน

ความเที่ยงตรงคือหัวใจของเครื่องจักรจาก Tornos และ MultiSwiss เองก็เช่นเดียวกัน ไม่ว่าจะเป็นระบบควบคุมความเย็นของเครื่องจักรให้คงที่ ระบบการทำงานแบบครบวงจรในเครื่องเดียว ทั้งระบบป้อนวัตถุดิบและระบบกรองน้ำมันที่มาพร้อมถาดรอง ไปจนถึงระบบอินเด็กซ์แมกกาซีนของชุดสปินเดิลที่รวดเร็วเป็นพิเศษ ทำให้ผู้ผลิตได้รับรวดเร็วและความเที่ยงตรงสูงสุด นอกจากนี้ ยังสามารถลดต้นทุนลงได้ เนื่องจากมีค่าใช้จ่ายด้านเครื่องมือลดลง ไม่ต้องหยุดการทำงานบ่อยๆ เนื่องจากสามารถควบคุมเศษได้อย่างมีประสิทธิภาพ และด้วยขนาดที่เล็กของเครื่องจักรรุ่นนี้ ทำให้ได้ประสิทธิภาพการผลิตต่อตารางเมตรเพิ่มขึ้น

ยิ่งไปกว่านั้น ด้วยระบบการทำงานแบบครบวงจรในเครื่องเดียว ทำให้การฝึกผู้ควบคุมเครื่องกลายเป็นเรื่องง่าย เนื่องจากผู้ควบคุมเครื่องที่คุ้นเคยกับเครื่องจักรแบบหนึ่งสปินเดิลอยู่แล้วสามารถที่จะเปลี่ยนมาใช้เครื่องจักรของ Tornos ได้อย่างสะดวก ทั้งหมดนี้คือเหตุผลที่ทำให้ผู้ผลิตรายต่างๆ เลือกใช้เครื่องจักร MultiSwiss เป็นจำนวนมากกว่า 350 เครื่องทั่วโลก ซึ่งเป็นข้อพิสูจน์ที่ชัดเจนถึงคำมั่นสัญญาของ Tornos: เราพร้อมจะช่วยให้ งานกลึง ของคุณต่อเนื่องไร้ปัญหา