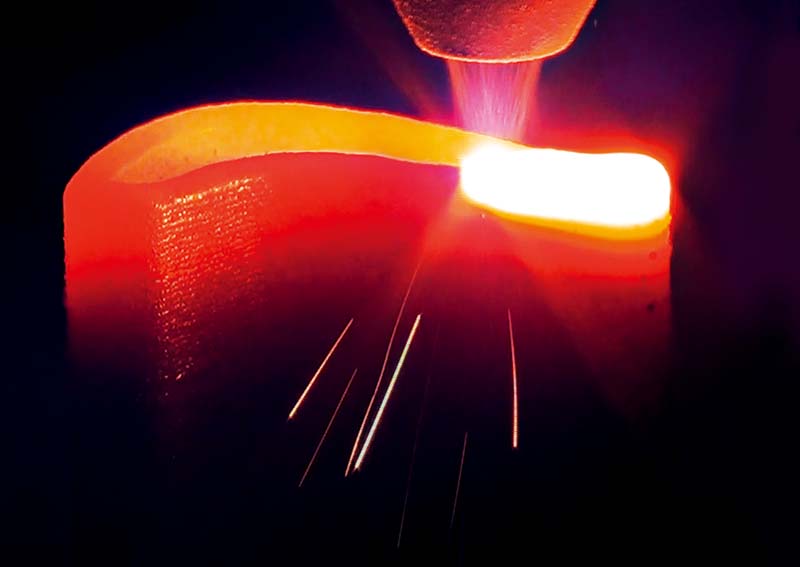

เครื่องกัด 5 แกน รุ่นเลเซอร์เทค 65 ดีอีดีไฮบริด (LASERTEC 65 DED) ของ DMGMori เป็นโซลูชั่นไฮบริดที่รวมการผลิตแบบเพิ่มวัสดุโลหะเลเซอร์หัวตัดผงวัสดุกับเครื่องกัด 5 แกนในเครื่องเดียว เครื่องนี้ดำเนินการกัดระหว่างกระบวนการผลิตแบบเพิ่มวัสดุโลหะเลเซอร์ได้ ทำให้จัดการบริเวณที่เข้าถึงไม่ได้บนชิ้นงานที่สำเร็จแล้ว ด้วยการกัด เลเซอร์เทค 65 ดีอีดีไฮบริดมีประสิทธิภาพยอดเยี่ยมในการใช้งานได้หลากหลายรูปแบบ เช่น การกัดขึ้นรูปอากาศยานที่มีรูปร่างซับซ้อน และส่วนประกอบทางการแพทย์ รวมทั้งสารเคลือบเพื่อซ่อมแซมและทนต่อการสึกกร่อนของชิ้นส่วน

เครื่องกัด 5 แกน รุ่นเลเซอร์เทค 65 ดีอีดีไฮบริด มีหัวเลเซอร์ยึดด้วยแกนหมุนผ่านอินเตอร์เฟสเอชเอสเค และการเปลี่ยนเครื่องมือเป็นแบบอัตโนมัติ เมื่อหัวเลเซอร์หดกลับด้านนอกตัวเครื่องระหว่างการตัด การตัดด้วยสารลดอุณหภูมิสามารถทำได้ และมีการป้องกันหัวเลเซอร์ไม่ให้ตัดเศษ

เครื่องกัด 5 แกน รุ่นเลเซอร์เทค 65 ดีอีดีไฮบริดสามารถจัดการชิ้นงานที่มีขนาดและน้ำหนักได้ถึง φ500 × 400 มม. และ 600 กก. การออกแบบเครื่องที่ใช้พื้นที่น้อยด้วยฐานเครื่องขนาดประมาณ 25 ตารางเมตรเป็นคุณสมบัติที่โดดเด่นของเครื่องไฮบริดนี้

Article by: DMG MORI COMPANY LIMITED

https://en.dmgmori.com/ << Click Here