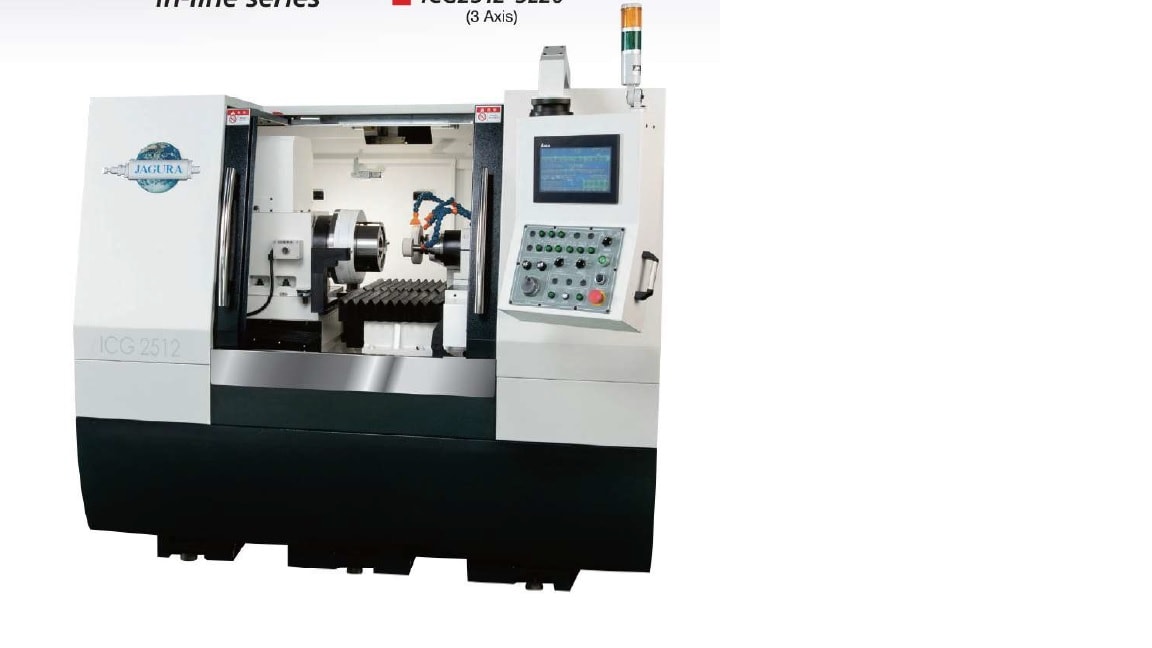

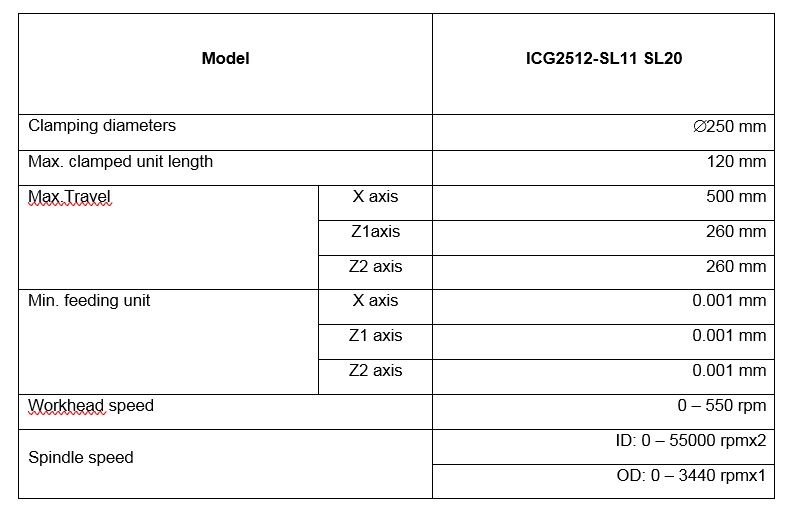

เครื่องเจียรภายในและแบบทรงกระบอกตระกูล in-line รุ่น ICG2512-SL11 และ SL20

คุณสมบัติที่สำคัญที่สุดของเครื่องเจียรภายในและแบบทรงกระบอกของ Jagura CNC ก็คือ ส่วนเจียรสามารถออกแบบได้ตามชิ้นงานของลูกค้า และความสามารถในการออกแบบได้เองนี้เป็นสิ่งที่เราภูมิใจมากที่สุด

Jagura สามารถตอบโจทย์เพื่อสนองความต้องการของลูกค้าได้อย่างดี ทั้งในการประยุกต์ในงานการเจียรภายใน การเจียรภายนอก และการเจียรผิวหน้า (End-Face) Jagura สามารถออกแบบโครงสร้างกลไกการออกแบบตามชิ้นงาน ทั้งในเรื่อง Clamping Swing และความยาวชิ้นงาน นอกจากนี้ ยังสามารถกำหนดการวางตำแหน่ง Spindle ในการทำงานตามความต้องการของลูกค้าได้ด้วย ไม่เพียงเท่านั้น ในการจับชิ้นงานหรือแคล้มปิ้ง Jagura มีวิธีจับชิ้นงานที่มากมายหลายแบบ เช่น การแคล้มปิ้งด้วย Hydraulic Soft Chuck การแคล้มปิ้งด้วย Collet การแคล้มปิ้งด้วย 3 Jaw Chuck และการแคล้มปิ้งด้วย Magnetic Chuck และในด้านระบบควบคุม Jagura พัฒนาระบบควบคุมสองแบบได้แก่ 1. แบบ EASY CNC และ 2. แบบ CNC สำหรับการประยุกต์การเจียรแบบต่างๆ

Grinding ID/OD Parts Let’s Talk

ประยุกต์ใช้ได้กับอุตสาหกรรม Collet อุตสาหกรรม Gear(เกียร์) อุตสาหกรรม Bush (เครื่องสวมเพลา) อุตสาหกรรมระบบ Automation อุตสาหกรรม Hydraulic และ Pneumatic รวมทั้งอุตสาหกรรมแม่พิมพ์ทั้งหลาย (Mold & Die)

Slide-Ways: ผ่านการอบชุบด้วยความร้อน และเจียรอย่างละเอียด เพื่อให้เครื่องจักรนี้สามารถทำงานได้อย่างต่อเนื่องไม่มีสะดุดและแม่นยำ

Feed axes (แกนป้อน): ทั้งแกน X และ Z มี บอลสกรู (ball screw) ที่แม่นยำ และมีเซอร์โวมอเตอร์ servo motors โดยเซอร์โวมอเตอร์จะขับเคลื่อนบอลสกรูโดยตรง ทำให้เกิดความแม่นยำในการวางตำแหน่งและความเสถียรในการป้อน

Workhead: Spindle (แกนหมุน) จะทำงานบน Roller Bearings ที่มีความละเอียดสูง ทำให้เกิดความแม่นยำสูง มั่นคง และทำงานได้อย่างเงียบ

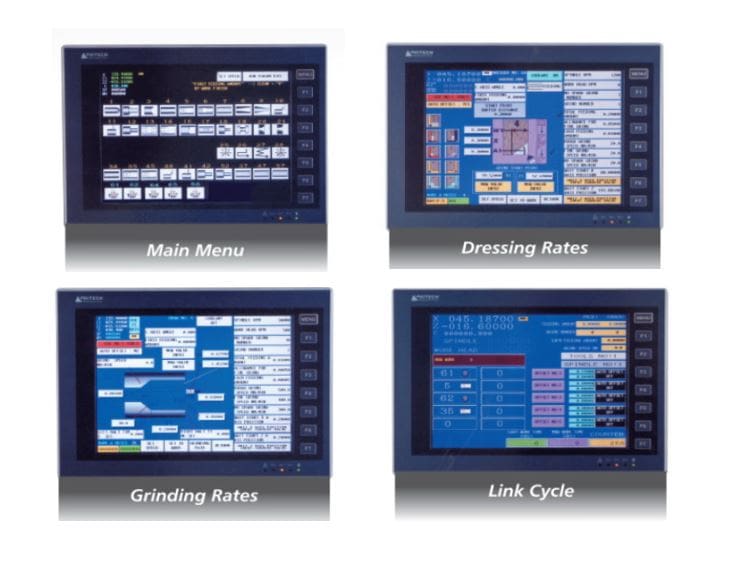

ระบบ Easy CNC และ CNC Software และ Dialogue HMI (โปรแกรมการทำงานเพื่อเชื่อมมนุษย์และเครื่องจักร)

CNC control ออกแบบมาพิเศษสำหรับการเจียรแบบ ID & OD Profile โดยระบบควบคุม CNC นี้สร้างโดย MITSUBISHI แต่มันใช้ซอฟต์แวร์ขั้นสูงที่พัฒนาโดย JAGURA โดยเฉพาะ และยังมี JAGURA Dialogue HMI ที่ไม่เหมือนกับระบบ CNC ทั่วไป ที่ใช้รหัส G และ M ที่ซับซ้อน ระบบของเราเรียนรู้และใช้งานง่าย ช่วยให้ผู้ใช้งาน JAGURA CNC ประหยัดเวลาและเงินในการอบรมอีกด้วย

JAGURA Dialogue HMI แบ่งออกเป็น 4 ส่วนหลักดังนี้ 1. Main Menu 2. Dressing Programs 3. Grinding Path Programs และ 4. Program Links ผู้ใช้งานเพียงเลือก Dressing Pattern และ Grinding Path จากนั้นก็ป้อนข้อมูลเพื่อประมวลผล และเครื่องจักรก็พร้อมทำงาน JAGURA Dialogue HMI เป็นโซลูชั่นที่ดีที่สุดสำหรับงานเจียร โดยเฉพาะงานเจียรทีมีโปรไฟล์ซับซ้อน และด้วย Graphic Directory ผู้ใช้งานสามารถแบ่งกระบวนการเจียรที่ซับซ้อนเป็นขั้นตอนย่อยทีละงานได้ ขั้นแรก ให้เลือกโปรแกรมการเจียรที่โหลดไว้แล้วมาหนึ่งอย่าง (Pre-Loaded Grinding Program) จากการเจียร ID, Taper, Radius หลังจากเลือกจากรายการได้แล้ว ผู้ปฏิบัติงานสามารถเลือกกำหนด ปริมาณการป้อน (Feed Volume) การป้อนแต่ละรอบ (Individual Cycle Feed) ความเร็วแกนหมุนที่ป้อน (Speed Feed Spindle RPM) และความยาวในการเจียร (Grinding Length)

Article by: Thaimach Sales & Service Co., Ltd. & MEGA Tech