เครื่องพั้นชิ่ง Punching Machine ได้ถูกพัฒนาอย่างต่อเนื่องเพื่อการผลิตที่มีคุณภาพและประสิทธิภาพที่ดีมากขึ้น Procurement Center ได้เห็นถึงคุณสมบัติของเครื่องพั้นชิ่ง Punching Machine HACO Q Series ที่มีความยืดหยุ่นในการทำงานสูง ช่วยให้ผู้ผลิตได้ชิ้นงานรวดเร็ว แม่นยำ และมีประสิทธิภาพที่สูง ทาง MEGATech จึงขอเป็นสื่อกลางที่จะนำเสนอเครื่องพั้นชิ่ง Punching Machine ที่ช่วยให้การผลิตของคุณดียิ่งขึ้น

ความต้องการของลูกค้าสมัยใหม่มีส่วนผลักดันการผลิตแผ่นโลหะไปสู่แนวทางใหม่ในช่วงไม่กี่ปีที่ผ่านมา แม้ว่าประสิทธิภาพการผลิตจะเป็นปัจจัยสำคัญในกระบวนการผลิตมาโดยตลอดก็ตาม แต่ความต้องการในการปรับแต่งได้มากขึ้นและการดำเนินการผลิตที่น้อยลงนั้นเน้นที่ความยืดหยุ่นเป็นเรื่องสำคัญ การผลิตชิ้นงานโลหะที่ลักษณะเหมือนกันทุกอย่างนั้นไม่ใช่มาตรฐานอีกต่อไป และเครื่องจักรที่มีเวลาหยุดทำงานนานระหว่างการผลิตเนื่องจากการตั้งค่าเครื่องจักรให้ อาจจะสร้างแรงกดดันต่อความสามารถในการทำกำไรมากขึ้น

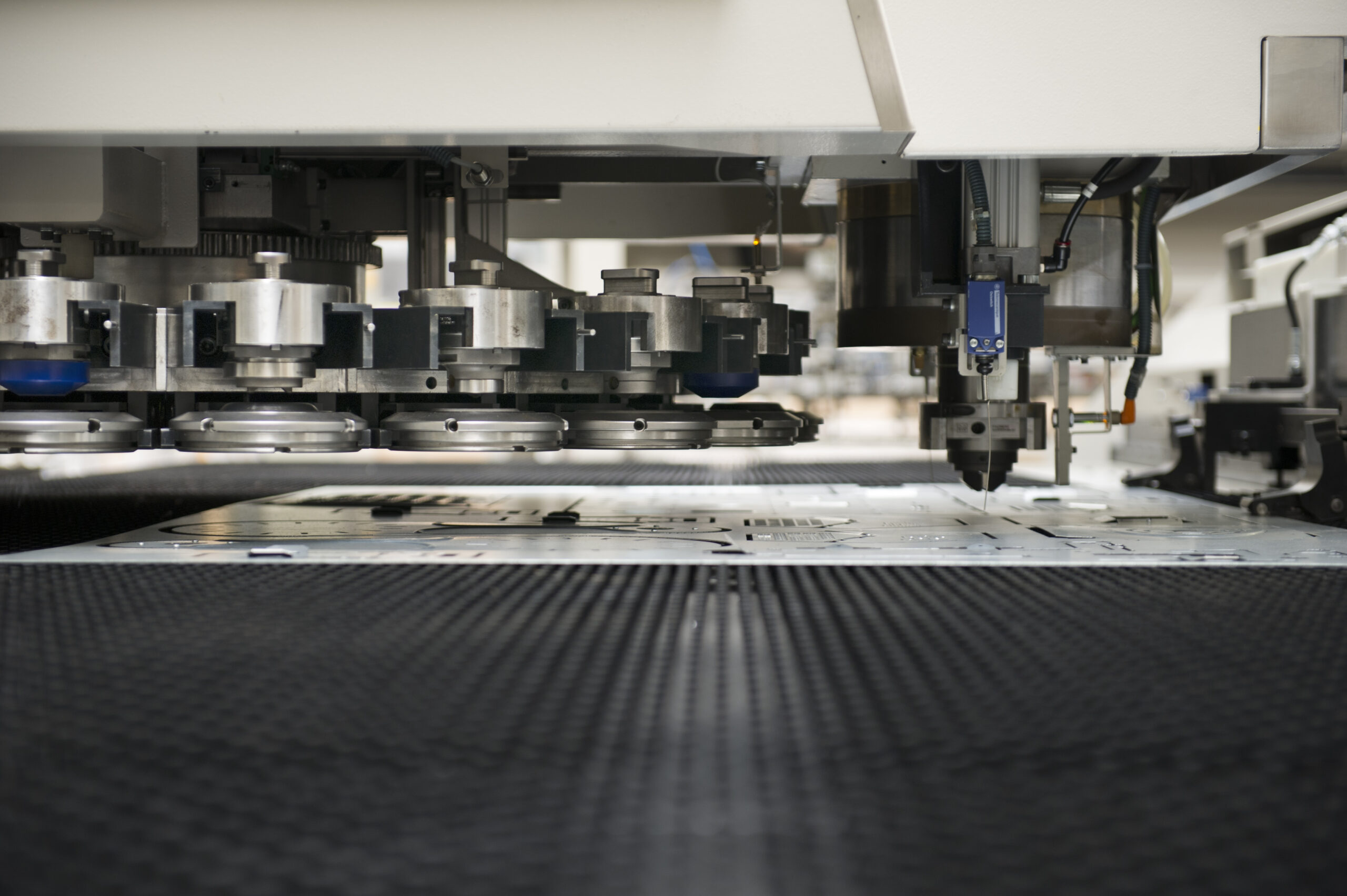

เครื่องปั๊มโลหะ มีความยืดหยุ่นตั้งแต่เริ่มต้นกระบวนการ ซึ่งตรงกันข้ามกับเครื่องจักรที่ใช้ในการผลิตโลหะแผ่นประเภทอื่น เครื่องปั๊มโลหะติดตั้งชุดเครื่องมือซีเอ็นซี CNC เช่น รุ่น Q5 จาก HACO มีกระบวนการผลิตโดยไม่ต้องใช้การทำงานขั้นที่สอง ชิ้นงานที่ขึ้นรูปแล้วคือ ชิ้นงานสำเร็จรูปที่พร้อมสำหรับการขายหรือนำไปใช้ตามวัตถุประสงค์จริง เครื่องปั๊มโลหะติดตั้งชุด เครื่องมือซีเอ็นซี CNC สามารถดัด ตัด ต๊าปเกลียว และอื่นๆ ได้เพียงเครื่องเดียว สามารถลดความจำเป็นที่ต้องใช้เครื่องจักรอื่นๆ และเวลาการติดตั้ง/ขนส่งในระหว่างกระบวนการผลิตได้เป็นอย่างดี

ด้วยหัวเจาะไฮดรอลิกเซอร์โวความเร็วสูงขนาด 22 หรือ 30 ตัน แกนหมุนสำหรับชุดเครื่องมือทั้งหมด และพารามิเตอร์การประมาณค่าในช่วงมาตรฐาน ทำให้เครื่องปั๊มโลหะรุ่น HACO Q5 จึงเป็นเครื่องเจาะซีเอ็นซี CNC ที่สมบูรณ์แบบและยืดหยุ่นที่สุด โต๊ะรองรับแผ่นขัดขนาดใหญ่เต็มพื้นที่และกระบอกสูบปรับตำแหน่งมาตรฐาน ช่วยให้สามารถผลิตโลหะแผ่นขนาดมาตรฐานได้อย่างง่ายดาย

ด้วยชุดเครื่องมือที่รองรับ turret tool ที่แตกต่างกันถึง 20 แบบ ทำให้สามารถใช้งานได้ทุกรูปแบบ การเปลี่ยนเครื่องมือจะใช้เวลาน้อยที่สุด และสามารถใช้เครื่องมือน้อยกว่าเครื่องมือชนิดไม่หมุนแบบเดิมถึง 70% ซึ่งจะช่วยลดการเวลาหยุดทำงานของเครื่องจักรเนื่องจากการติดตั้งและตั้งค่าเครื่องมือแต่ละตัวได้เป็นอย่างดี

ประกอบกับประตูรางขนาดใหญ่ที่มีตัวเซ็นเซอร์ชิ้นงานและสายพานลำเลียงในตัว ทำให้เครื่องปั๊มโลหะรุ่น Q ซีรีย์ จาก HACO สามารถทำให้กระบวนการผลิตเป็นไปโดยอัตโนมัติและทำงานได้เป็นเวลานานขึ้น โดยไม่ต้องมีผู้ควบคุม นอกจากนี้การคัดแยกชิ้นส่วนอัตโนมัติยังช่วยลดกระบวนการจัดการหลังการผลิตให้ดียิ่งขึ้นไปอีก โดยประตูรางขนาดใหญ่สามารถคลุมชิ้นส่วนขนาดใหญ่ได้อย่างง่ายดายด้วยความสูงการดัดสูงสุด 70 มม. ซึ่งช่วยลดขั้นตอนการดัดเพิ่มในครั้งที่สองได้ด้วยความสามารถการขึ้นรูปและการดัดที่ยอดเยี่ยมของเครื่องปั๊มโลหะ HACO Q5 ด้วยความสูงในการดัดงอที่ 3.0 นิ้ว (75 มม.) ในมุมต่างๆ และแม้กระทั่งชิ้นส่วนที่วางซ้อนกันในตำแหน่งอื่นที่ไม่ใช่มุมมาตรฐาน 0° – 45° และ 90° เครื่องปั๊มโลหะของคุณจะกลายเป็นเครื่องผลิตชิ้นงานแบบมัลติฟังก์ชั่นที่ยอดเยี่ยม

ตัวควบคุมทำงานแบบหน้าจอกราฟิก TPS 84S มีการทำงานที่เป็นมิตรกับผู้ใช้ ซึ่งมีทุกสิ่งที่คุณต้องการเพื่อให้เหมาะกับความต้องการสูงในงานปั๊มโลหะยุคใหม่ การควบคุมการทำงานที่ความเร็วสูง การขึ้นรูปชิ้นงานที่รวดเร็ว และอินเทอร์เฟซผู้ใช้ที่ใช้งานง่าย ส่งผลให้ระบบนี้เป็นนวัตกรรมใหม่ที่สามารถจัดการงานทั้งแบบเรียบง่ายและแบบซับซ้อนได้ ตั้งแต่แนวคิดเริ่มต้นไปจนถึงการผลิตชิ้นงาน ซึ่งตัวควบคุมการทำงานแบบหน้าจอกราฟิก TPS 84S คือ เพื่อนร่วมงานที่ดีเยี่ยมในอุดมคติของคุณ ความก้าวหน้าในการเขียนโปรแกรมซอฟต์แวร์นำเสนอความเป็นไปได้ในการใช้เครื่องมืออัตโนมัติและการประกอบชิ้นส่วนอัตโนมัติ ซึ่งช่วยลดเวลาจากการออกแบบไปจนถึงชิ้นงานที่เสร็จสิ้นโดยสิ้นเปลืองน้อยที่สุด

Article by: Procurement Center (Thailand) Company Limited & MEGA Tech

Click Here >> www.thaisheetmetal.com