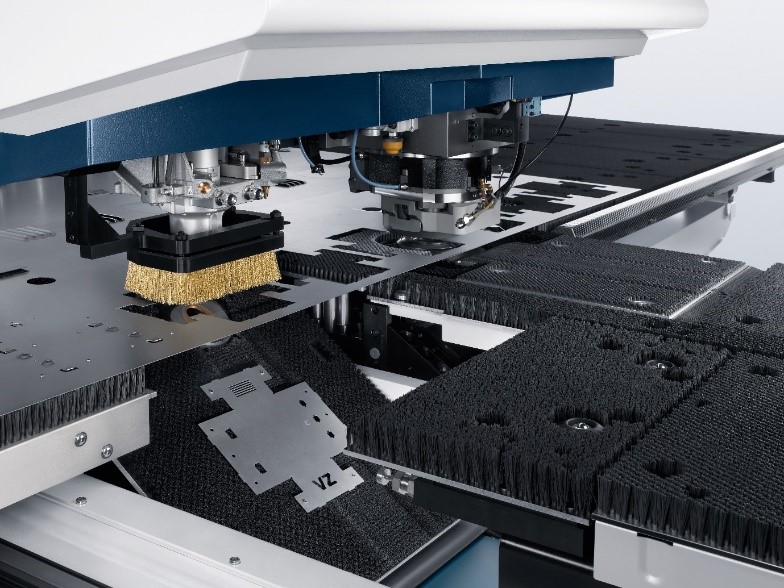

ระบบอัตโนมัติสามารถช่วยในการประหยัดต้นทุนและเพิ่มประสิทธิภาพในกระบวนการผลิตได้ โดยหัวใจสำคัญจะต้องเป็นระบบอัตโนมัติที่สามารถเชื่อถือได้และมีความปลอดภัยสูง ระบบอัตโนมัติสามารถนำไปใช้ในกระบวนการโหลดแผ่นโลหะและชิ้นส่วนก่อนการตัด กระบวนการขนถ่ายชิ้นส่วนที่ตัดเสร็จแล้ว , แผ่นข้อต่อขนาดเล็กและเศษเหล็กที่เหลือ นอกรวมถึงกระบวนการจัดการโครงและเศษเหล็กและการคัดแยกชิ้นส่วนขนาดเล็ก โดยที่กล่าวมาทั้งหมดสามารถทำได้โดยอัตโนมัติด้วยเครื่องจักรและระบบอัตโนมัติที่ทำงานร่วมกันได้อย่างลงตัว SheetMaster Compact คือส่วนช่วยในการโหลดและอันโหลดแผ่นโลหะ และ SortMaster Compact คือส่วนช่วยในการแยกชิ้นงานและเศษเหล็ก ซึ่งทั้งหมดจะอยู่ในระบบอัตโนมัติจาก TRUMPF

ประโยชน์มากมายจากการทำงานของเครื่องพั้นชิ่ง Punching Machine และระบบอัตโนมัติ เช่น การเพิ่มผลผลิตเนื่องจากการอัตราการใช้เครื่องจักรที่เยอะขึ้นและลดระยะเวลารอคอยสินค้าในโรงงาน นอกจากนี้ ระบบอัตโนมัติยังช่วยเพิ่มความน่าเชื่อถือของกระบวนการ เพิ่มประสิทธิภาพและปรับปรุงระบบความปลอดภัยในระหว่างกระบวนการพั้นชิ่งได้เป็นอย่างดี ระบบอัตโนมัติมีกระบวนการผลิตที่มีความแปรปรวนน้อยกว่าการใช้แรงงานคน สามารถควบคุมได้ง่ายและก่อให้เกิดความสม่ำเสมอของคุณภาพผลิตภัณฑ์ที่มากขึ้นอีกด้วย

อนาคตอันยาวไกลของการพั้นชิ่ง

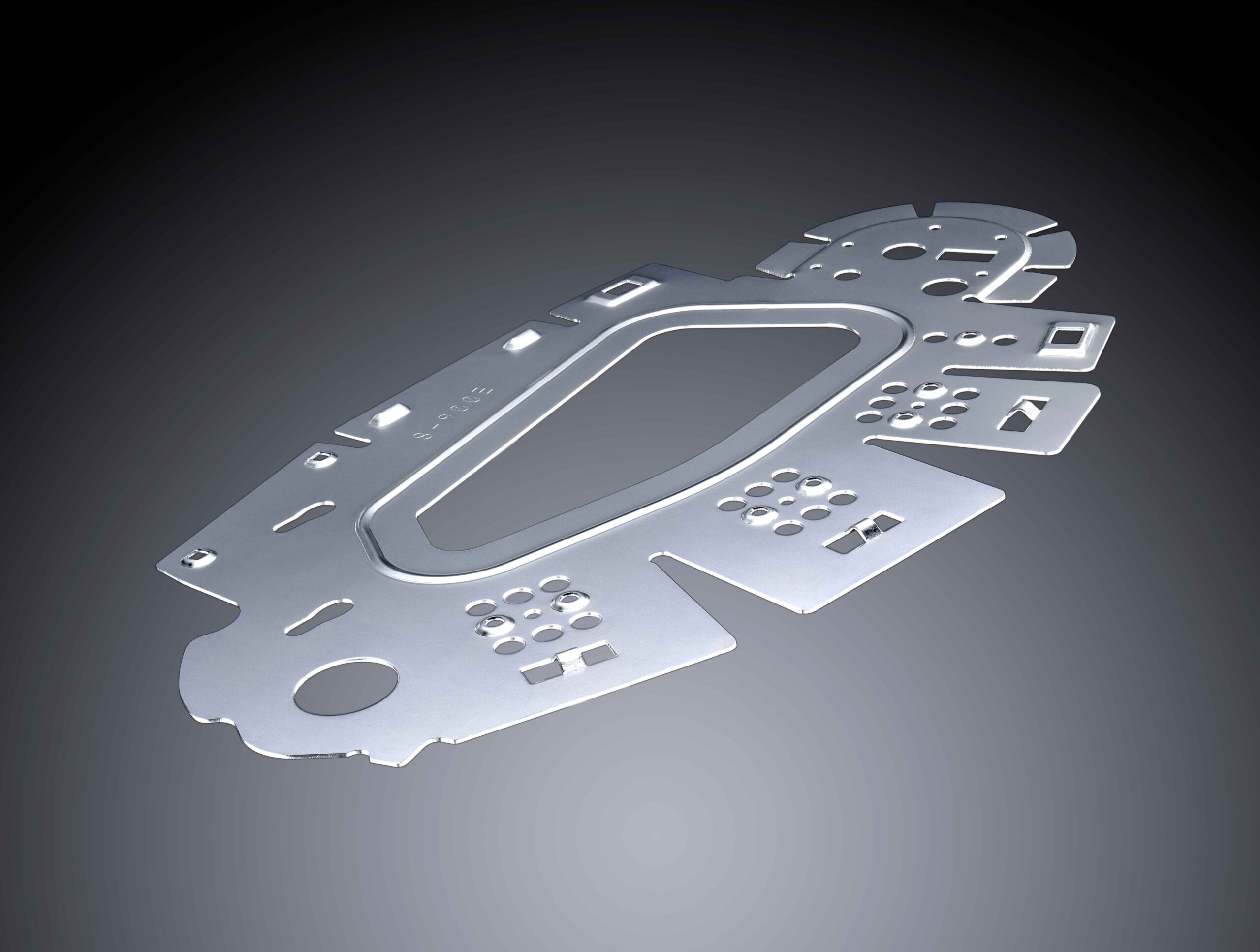

เทคโนโลยีการพั้นชิ่ง Punching Machine หรือการเจาะโลหะแผ่นได้รับการพัฒนาอย่างต่อเนื่องในไม่กี่ปีที่ผ่านมา เครื่องจักรคุณภาพสูงในขณะนี้ จะไม่มีการทิ้งร่องรอยใด ๆ รวมไปถึงการตั้งค่า การจัดเรียงแผ่น และการนำชิ้นงานออกได้ง่ายกว่าที่เคยเป็นมา เพราะความต้องการด้านคุณภาพของลูกค้าที่เพิ่มขึ้นแต่ปริมาณการผลิตต่อล็อตลดลง ดังนั้นการคำนวณค่าใช้จ่ายที่แม่นยำนั้นจึงสำคัญมาก แต่ก็ไม่ใช่เรื่องง่ายอย่างแน่นอนเมื่อต้องผลิตชิ้นงานโดยใช้เครื่องจักรหลายเครื่อง ปัญหานี้มีทางออก ด้วยการผสมผสานสองเทคโนโลยี –TruMatic 1000 fiber PUNCH LASER MACHINES จาก TRUMPF ที่รวม การพั้นชิ่งและการตัดด้วยเลเซอร์ไว้ในเครื่องเดียว

การปรับเปลี่ยนและผสานการใช้งานกับเลเซอร์โซลิดสเตต TruDisk 3 กิโลวัตต์

ด้วยฟังก์ชันที่ต่อขยายได้ ทำให้เครื่องพั้นชิ่ง Punching Machine TruPunch 1000 เป็นจุดเริ่มต้นที่สมบูรณ์แบบสู่โลกของการพั้นชิ่งในระดับมืออาชีพ ที่รองรับโลหะแผ่นที่ความหนาสูงสุดถึง 6.4 มม. อัตราการพั้นชิ่งสูงสุด 600 ครั้งต่อนาที ใชพื้นที่ติดตั้งเพียง 6.5 x 4.9 เมตร และด้วยตัวเครื่องแบบสแตนด์อโลน TruPunch 1000 จึงมีขนาดเล็กกว่ารุ่นก่อนถึง 15 เปอร์เซ็นต์

การปฏิวัติเทคโนโลยีพั้นชิ่งเฮด

เครื่องพั้นชิ่ง Punching Machine ที่นำเสนอเทคโนโลยีไดรฟ์ออกแบบใหม่ทั้งหมด ซึ่งมีความสำคัญต่อความสำเร็จของแนวคิดแบบโมดูลาร์ “Delta Drive” ที่ได้รับการจดสิทธิบัตรครั้งใหม่ในโลกของเทคโนโลยีการเจาะแผ่นโลหะในทางอุตสาหกรรม ความลับของ Delta Drive คือไม่จำเป็นต้องย้ายแผ่นโลหะและโต๊ะทำงานในแกน y ซึ่งปกติแล้วเป็นข้อกำหนดที่สำคัญของกระบวนการแปรรูปโลหะแผ่น ซึ่งทำได้โดยทำให้หัวเจาะเคลื่อนที่ไปในทิศทางนั้นๆอย่างรวดเร็ว นี่คือการปฏิวัติเทคโนโลยีพั้นชิ่ง Punching Machine เฮดอย่างแท้จริง

ระบบจัดเรียงชิ้นงานสำเร็จอัตโนมัติ

ทั้ง TruPunch 1000 และ TruMatic 1000 fiber รองรับระบบจัดเรียงชิ้นงานที่ตัดเสร็จที่ขนาดสูงสุดถึง 180 มม. × 180 มม. โดยอัตโนมัติ ชิ้นส่วนที่ผ่านกระบวนการทั้งหมดจะถูกส่งลงไปในรางไปสู่กล่องคัดแยกซึ่งเคลื่อนที่เป็นเส้นตรง โดยถูกจัดเรียงลงกล่องที่รองรับ (ขนาด 400 มม. × 300 มม.จำนวน 4 กล่อง) กล่องที่เรียงอยู่ด้านล่างตัวเครื่องจักร ซึ่งผู้ปฏิบัติงานสามารถดึงเลื่อนออกมาได้อย่างง่ายดาย

เนื่องจากการเคลื่อนที่ของหัวเจาะที่เป็นนวัตกรรมใหม่ ตัวเครื่องจักรนี้จึงมีทางเลือกที่หลากหลายในการเอาชิ้นงานออก อีกวิธีคือช่อง Sorting Flap สำหรับชิ้นงานขนาดใหญ่เพิ่มเติม ซึ่งเป็นตัวเลือกในอุปกรณ์เสริมสำหรับ TruPunch 1000 และติดตั้งเป็นมาตรฐานใน TruMatic 1000 fiber โดย สามารถติดตั้งเซ็นเซอร์เพิ่มเติมเพื่อตรวจจับว่าชิ้นงานทั้งหมดได้ถูกนำออกจากพื้นที่ทำงานของเครื่องจักรแล้ว

ประโยชน์อันคุ้มค่าจาก TruMatic 1000 fiber PUNCH LASER MACHINES

1. การผสมผสานอย่างลงตัวและคุ้มค่า

ด้วยแม่พิมพ์พั้นชิ่งที่ตอบโจทย์ชิ้นงานรูปทรงต่างๆและการขึ้นรูปมาตรฐาน ในขณะที่เลเซอร์ตัดรูปทรงที่ซับซ้อนมากยิ่งขึ้น นั่นทำให้คุณผลิตชิ้นงานได้หลากหลาย และเหมาะกับการผลิตตามคำสั่งซื้อที่หลากหลายและท้าทายในเครื่องจักรเพียงเครื่องเดียวลดเวลา

2. อิสระเต็มที่ด้วยแนวคิดโลจิสติก์แบบลีน

เพราะเราได้รวมขั้นตอนกระบวนการตัด เจาะ และขึ้นรูปในเครื่องจักรเพียงเครื่องเดียว จะช่วยลดความเสี่ยงในการคำนวนค่าใช้จ่ายและลดการใช้พื้นที่ติดตั้งเครื่องจักร รวมไปถึงระยะเวลารอและเวลางานที่ใช้ในการตั้งค่าและการทำงานลดลง คุณประหยัดเงินได้มากขึ้น

3. รวมทุกการทำงานที่ดีที่สุด

การรวมการขึ้นรูปกับการตัดด้วยเลเซอร์ไว้ด้วยกันไม่เพียงช่วยลดของเสียที่คุณผลิตเท่านั้น แต่ยังช่วยให้คุณผลิตชิ้นส่วนที่มีความแม่นยำสูงอย่างมีคุณภาพที่คุณไม่สามารถทำได้เมื่อผลิตด้วยเครื่องจักรหลายเครื่อง

4. ด้วยกระบวนการที่สั้นลง โลจิสติกส์จึงเป็นเรื่องง่ายๆ

ด้วยระบบอัตโนมัติที่ลงตัวครบครัน เครื่องจักรของคุณจะสามารถจัดการชิ้นส่วนทั้งหมดได้โดยอัตโนมัติ ไม่ว่าจะเป็นการโหลด การผลิต การจัดเรียง การวางซ้อน การอันโหลด และการจัดเก็บ เรียกได้ว่าไร้ขีดจำกัดความสามารถในการขนถ่าย ดังนั้นเครื่องจักรของคุณจึงทำงานตลอดเวลาได้ตามต้องการของคุณ

Article by: Trumpf Co., Ltd. & MEGA Tech