เนื่องจากไฟเบอร์เลเซอร์ได้รับการยอมรับและมีส่วนแบ่งทางการตลาดที่เพิ่มขึ้นอย่างมากในกระบวนการผลิตในอุตสาหกรรม โดยเฉพาะอย่างยิ่งการมขีดความสามารถในการผลิตในระดับที่เหนือกว่า เครื่องตัดเลเซอร์ชนิด CO2 ที่ได้รับการยอมรับมากขึ้นในปัจจุบัน ผู้ผลิคระดับโลกจึงได้นำเสนอนวัตกรรมใหม่ให้กับผู้ผลิตในสาขานี้

Platino 2.0 Fiber

ถูกออกแบบขึ้นเพื่องานของคุณโดยเฉพาะ ด้วยเครื่องเลเซอร์ Platino Fiber รุ่นใหม่ เวอร์ชั่น 2.0 ของ Prima Power ที่ถูกพัฒนาให้มีประสิทธิภาพสูงสุดเพื่อการแข่งขันของลูกค้า ด้วยออฟชั่นของอุปกรณ์เสริมที่เหมาะสมกับงานแต่ละชนิดที่ตรงกับความต้องการ เช่น

Smart Cut: ฟังชั่นนี้สำหรับการตัดงานบางที่ต้องการการตัดด้วยความรวดเร็ว (ความหนาสูงสุดไม่เกิน 5 มม.) โดยเทคโนโลยีการตัดด้วยไนโตรเจน ทำให้สามารถลดเวลาการตัดงานได้ลงถึง 30% อุปกรณ์เสริมชุดนี้ยังประกอบไปด้วย ฟังชั่นการเคลื่อนที่ของแกนอย่างชาญฉลาดและฟังชั่นการตัดตาข่าย

Max Cut: ฟังชั่นสำหรับการตัดงานหนาปานกลางให้เร็วขึ้น ซึ่งสามารถลดเวลาการตัดงานลงได้ถึง 40% โดยการเพี๊ยซงานด้วยไนโตรเจน ทำให้สามารถเพี๊ยซงานได้อย่างมีประสิทธิภาพและรวดเร็ว

Night Cut: เพื่อการตัดงานอย่างรวดเร็วและปลอดภัยด้วยอุปกรณ์ LPM (Laser Piecing Monitor) ในขณะที่ไม่มีพนักงานเฝ้าประจำเครื่อง เช่น ในกะกลางคืน ฟังชั่นนี้ยังประกอบไปด้วย การตรวจสอบการเกิดพลาสมา การเริ่มตัดงานใหม่อีกครั้งและการส่ง E-mail แจ้งสถานะ เป็นต้น

นวัตกรรมที่ได้ถูกทดลอง ทดสอบมาแล้วอย่างเข้มข้น

ด้วยรูปแบบโครงสร้างของเครื่อง Platino กว่า 1,800 เครื่องที่ติดตั้งอยู่ทั่วโลก จึงเป็นที่มั่นใจได้ว่า เครื่องได้ถูกทดลอง ทดสอบมาแล้วถึงประสิทธิภาพ ความคล่องตัวและความเสถียร ของเครื่อง Platino

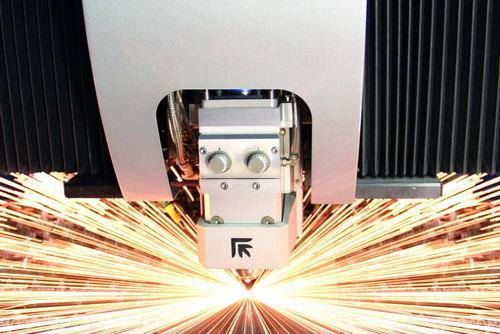

Platino 2.0 มีขนาดตั้งแต่ 2kw ถึง 6kw ให้เลือก หัวเลเซอร์ของ Platino 2.0 ถูกสร้างขึ้นมาเพื่อ Fiber Laser โดยเฉพาะ โดยมีเลนส์แค่เลนส์เดียว สามารถติดตั้งอุปกรณ์เสริมการเปลี่ยน Nozzle โดยอัตโนมัติ มีเซนเซอร์ป้องกันหัวเลเซอร์เสียหาย และยังประกอบไปด้วยอุปกรณ์ที่ทำให้การทำงานมีความแม่นยำ อย่างมีประสิทธิภาพ จึงทำให้เครื่องจักรสามารถทำงานได้อย่างต่อเนื่องตลอด 24 ชั่วโมง

โครงฝาเครื่องมี 2 แบบให้เลือก คือ แบบ Lean ที่ราคาย่อมเยาและติดตั้งได้ง่ายรวดเร็ว และแบบ Open ซึ่งสามารถเปิดกว้างได้มากกว่า

Platino 2.0 มาพร้อมกับอุปกรณ์เพื่อการรองรับการทำงานด้วยระบบอัตโนมัติ เช่น ระบบป้อนงาน อัตโนมัติ ระบบเก็บเรียงชิ้นงานที่ตัดเสร็จอัตโนมัติ หรือ การต่อเข้ากับระบบสายพานการผลิต เช่น FMS (Flexible Manufacturing System)

AMADA ENSIS-3015AJ

เครื่องตัดไฟเบอร์เลเซอร์รุ่นล่าสุดของอะมะดะ มีคุณสมบัติพิเศษคือสามารถปรับเปลี่ยนรูปร่างของลำแสงเลเซอร์ให้เหมาะกับชนิดและความหนาของวัสดุที่จะตัดได้ ซึ่งโดยทั่วไป จะต้องอาศัยการเปลี่ยนเลนส์แบบแมนนวล (เปลี่ยนด้วยตัวเอง) เพื่อช่วยเปลี่ยนขนาดจุดและระยะโฟกัสชดเชยแทน แต่ด้วยความสามารถนี้ จึงสามารถทำงานได้เองได้โดยอัตโนมัติ

หลักการที่อยู่เบื้องหลังความสามารถนี้ คือระบบปรับเปลี่ยนลำแสงแบบอัตโนมัติ ( variable beam control system) เมื่อเราต้องการตัดวัสดุบาง ระบบจะทำการปรับรูปร่างลำแสงให้มีขนาดเล็กแหลม ทำให้มีความหนาแน่นพลังงานสูง ดังนั้นจึงสามารถตัดงานได้ด้วยความเร็วสูง เมื่อเราต้องการตัดวัสดุหนา ระบบจะทำการปรับรูปร่างลำแสงให้มีขนาดใหญ่ขึ้น เพื่อขยายขนาดร่องของรอยตัด (kerf width) ให้กว้างขึ้น ทำให้ก๊าซช่วยตัด (assisted gas) สามารถเป่าพ่นวัสดุที่หลอมละลายหลุดออกไปทางด้านล่างของรอยตัด ได้ง่ายยิ่งขึ้น ทำให้สามารถตัดงานได้อย่างมีเสถียรภาพ (stable cutting)

เทคนิคที่ใช้ในกระบวนการนี้มีพื้นฐานมาจากการสั่งสมประสบการณ์ความเป็นมืออาชีพในด้านเลเซอร์ ซึ่งอะมะดะเป็นผู้ผลิตทั้งตัวเครื่องจักรและพัฒนาตัวกำเนิดลำแสงไฟเบอร์เลเซอร์ด้วยตัวเอง (AMADA’s original own fiber laser oscillator)

ผู้ใช้จะได้ประโยชน์อย่างเต็มที่จากการทำงานอย่างต่อเนื่องยาวนาน โดยแทบจะไม่ต้องคอยควบคุมดูแล และหยุดเครื่องเพื่อเตรียมงาน (set up) หรือปรับเปลี่ยนอุปกรณ์ ทำให้สามารถทำงานได้แบบอัตโนมัติ

การผลิตอย่างต่อเนื่องโดยไม่ต้องหยุดเตรียมงาน

นอกจากจะช่วยให้ไม่ต้องเปลี่ยนเลนส์แล้ว นวัตกรรม ENSIS-3015AJ ยังมีคุณสมบัติที่สำคัญอีกประการคือ ช่วยขยายขอบเขตความสามารถในการทำงาน (process range expansion) เพราะด้วยระบบปรับเปลี่ยนลำแสงดังที่ได้อธิบายไปแล้วข้างต้น ENSIS จึงสามารถใช้พลังงานลำแสงเลเซอร์ที่น้อยกว่าแต่ตัดงานได้หนาเท่ากับเครื่องเลเซอร์ทั่วไป (conventional laser cutting machine) ที่ต้องใช้กำลังวัตต์สูงๆ เช่น ในรุ่นขนาด 2000วัตต์ ที่สามารถตัดเหล็กได้หนาถึง 25มม. โดยยังคงคุณภาพไว้ได้อย่างน่าทึ่ง เมื่อเทียบกับเครื่องทั่วไปที่ต้องใช้กำลังถึง 4000 วัตต์

ผลที่ได้คือกระบวนการผลิตที่ต่อเนื่อง รวดเร็ว และมีคุณภาพสูง พร้อมทั้งยังช่วยประหยัดพลังงานได้อย่างน่าทึ่ง อีกทั้งยังสามารถเปลี่ยนหัวพ่นก๊าซ (nozzle) ได้เองโดยอัตโนมัติ ทำให้ตัดงานได้อย่างต่อเนื่อง มีประสิทธิภาพสูงสุด

ENSIS-3015AJ เหมาะสำหรับทั้งโลหะที่มีเหล็กเป็นส่วนประกอบและโลหะที่ไม่มีเหล็กเป็นส่วนประกอบ รวมถึงวัสดุที่สะท้อนแสงเลเซอร์ได้ดี (high reflect laser beam material) เช่น ทองแดง ทองเหลือ ไททาเนียม และใช้พื้นที่ในการติดตั้งเพียงเล็กน้อย