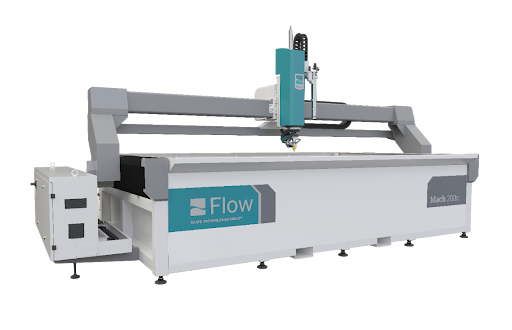

กระบวนการตัดด้วยวอเตอร์เจ็ท (Waterjet Flow Mach 200c) เป็นที่ยอมรับว่าเป็นกระบวนการตัดที่มีความหลากหลายและเติบโตเร็วที่สุดสำหรับอุตสาหกรรมการผลิตทั่วโลก นอกจากนี้กระบวนการด้วยวอเตอร์เจ็ท ยังคงช่วยเสริมและทดแทนเทคโนโลยีการตัดอื่นๆ ได้อย่างเป็นอย่างดี

คือการใช้กระแสน้ำแรงดันสูงพิเศษในการตัดวัสดุ และเติมวัสดุขัดผิวลงไป การตัดด้วยวอเตอร์เจ็ท (Waterjet Flow Mach 200c) เป็นกระบวนการตัดแบบเย็น ซึ่งจะช่วยลดความเสี่ยงจากความร้อนที่อาจเกิดขึ้นกับวัสดุ เช่น การบิดงอ การโก่งงอ หรือการแข็งตัว จึงเหมาะสำหรับวัสดุที่ไวต่อความร้อน ลดความจำเป็นในกระบวนการผลิตลำดับที่สอง เนื่องจากกระบวนการตัดด้วย วอเตอร์เจ็ท สามารถตัดวัสดุได้ทุกประเภท จึงช่วยเพิ่มประสิทธิภาพการใช้เครื่องจักรและสร้างผลตอบแทนจากการลงทุนได้อย่างยอดเยี่ยม

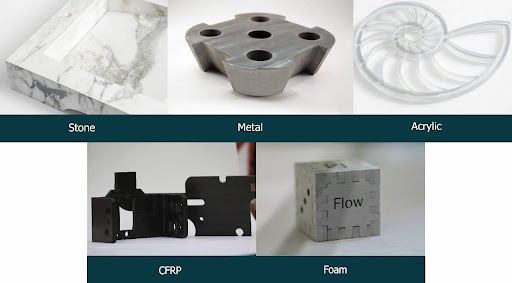

ด้วยกระบวนการตัดอันทรงพลังของวอเตอร์เจ็ท (Waterjet Flow Mach 200c) จึงสามารถตอบโจทย์กระบวนการผลิตได้ทุกโปรเจกต์ในโรงงานได้อย่างราบรื่น ไม่ว่าจะเป็นงานตัดหินที่มีรายละเอียดบางเฉียบ ,กระจกและโลหะ หรืองานเจาะรูอย่างรวดเร็วและงานตัดไททาเนียมที่มีขนาดหนา รวมถึงงานตัดโฟม ระบบวอเตอร์เจ็ทไม่เพียงแต่สามารถตัดวัสดุขั้นพื้นฐานเท่านั้น แต่ยังเหมาะสำหรับวัสดุที่ยากต่อการตัดได้เป็นอย่างดี เช่น โลหะผสมนิกเกิล ทองแดง คอมโพสิตคาร์บอนไฟเบอร์ ไฟเบอร์กลาส กระเบื้อง เซรามิกอุตสาหกรรม รวมถึงวัสดุอ่อน เช่น แผ่นยาง, โฟม และพลาสติก เป็นต้น

ไม่ว่าจะตัดวัสดุขนาดใดก็ตาม เครื่องตัดวอเตอร์เจ็ท (Waterjet Flow Mach 200c) มีให้เลือกหลายขนาดและหลายรูปแบบ เช่น โต๊ะทำงานขนาดเล็กคือ 1.3 ม. x 1.3 ม. ในขณะที่เครื่องอื่นๆ สามารถปรับขนาดให้เหมาะสมได้ เช่น โต๊ะทำงานขนาดใหญ่ 4 ม. x 24 ม. และสามารถทำงานด้วยหัวตัดหลายหัว ด้วยความหลากหลายนี้ทำให้เครื่องตัดวอเตอร์เจ็ทสามารถปรับให้เข้ากับขนาดการผลิตและกระบวนการการใช้งานที่แตกต่างกันได้อย่างลงตัว

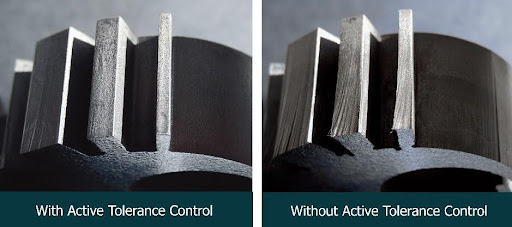

เครื่องตัดวอเตอร์เจ็ท (Waterjet Flow Mach 200c) จะแสดงผลของ stream lag และ taper ในขณะทำการตัดวัสดุ หากต้องการตัดให้มีค่าความคลาดเคลื่อน +/- 0.005” (+/- 0.13 มม.) ด้วยหัวตัดแบบธรรมดา ความเร็วในการตัดของเครื่องจะต้องลดลงเหลือประมาณ 15% ของความเร็วการตัดสูงสุด การลดความเร็วให้ช้าลงนี้จำเป็นเพื่อลดขอบมุมอันเกิดจาก stream lag และ ส่วนของ taper ที่จะก่อให้เกิดการเอียงเป็นช่อง V ขณะตัดด้วยความเร็วสูง ดังนั้นการตัดที่ช้าลงจะช่วยลดการเกิด stream lag แต่จะต้องใช้เวลามากขึ้นและมีค่าใช้จ่ายที่สูงขึ้น

Dynamic Waterjet ของเครื่องตัดวอเตอร์เจ็ท (Waterjet Flow Mach 200c) คือเทคโนโลยีที่ได้รับการจดสิทธิบัตร ซึ่งจะทำการปรับมุมหัวตัดอัตโนมัติเพื่อชดเชยการเกิด stream lag และ taper โดยขึ้นอยู่กับความเร็วในการตัดและประเภทของวัสดุที่ตัด ผลลัพธ์คือการตัดที่เร็วขึ้น 2 ถึง 4 เท่า และความแม่นยำในการตัดที่ได้คือ +/- 1 ถึง 3,000ของนิ้ว (+/- 0.03 ถึง 0.08mm) เทคโนโลยีนี้ช่วยให้เครื่องจักรสามารถเคลื่อนที่ได้เร็วขึ้น เมื่อมีการเกิด stream lag และ taper จะสามารถชดเชยได้ด้วยการปรับมุมหัวตัดได้สูงสุดถึง 10 องศา

ไม่ว่าจะเป็นการขึ้นรูปชิ้นงาน 2D หรือ 3D เพียงแค่ป้อนแบบลงในเครื่องตัดวอเตอร์เจ็ท (Waterjet Flow Mach 200c) แล้วให้เครื่องทำงานต่อไป ซอฟต์แวร์ FlowXpert จะเป็นผู้ดูแลกระบวนการผลิตทั้งหมด ซอฟต์แวร์จะสร้างเส้นทางการตัดตามแบบที่คุณนำเข้าหรือสร้างขึ้นโดยอัตโนมัติ โดยกำหนดจุดเริ่มต้นและจุดสิ้นสุดของหัวฉีดที่ถูกต้อง ตั้งค่าการชดเชยการตัดที่เหมาะสม และแสดงข้อผิดพลาดหรือแก้ไขข้อผิดพลาดของลวดลายก่อนที่ผู้ปฏิบัติงานจะเริ่มการตัด โดยจะหาทางตัดที่สั้นที่สุดและชาญฉลาดที่สุดสำหรับชิ้นงานของคุณ โดยลดการเคลื่อนที่ที่ไม่จำเป็นและช่วยประหยัดเวลาและวัสดุในการตัดให้ได้มากที่สุด

อีกปัจจัยเด่นของการตัดที่มีความยืดหยุ่นคือความสะดวกในการปรับเปลี่ยนกระแสน้ำในการตัด ผู้ปฏิบัติงานสามารถปรับพารามิเตอร์ต่างๆ เช่น ความเร็วและมุมของหัวฉีดน้ำได้อย่างง่ายดายตามความต้องการในการตัดที่แตกต่างกัน ด้วยระบบควบคุมคอมพิวเตอร์ที่ชาญฉลาด ส่งผลให้หัวฉีดน้ำ วอเตอร์เจ็ท (Waterjet Flow Mach 200c)สามารถตั้งตำแหน่งได้อย่างแม่นยำ และสามารถปรับเปลี่ยนความเร็วในการตัดได้แม้ในขณะกระบวนการตัดยังดำเนินอยู่ ซึ่งช่วยให้สามารถตัดรูปทรงที่ซับซ้อนและตัดขอบมุมต่างๆได้อย่างสวยงาม กระบวนการตัดที่เร็วขึ้นและมีประสิทธิภาพยังช่วยลดการใช้วัสดุสิ้นเปลือง ซึ่งช่วยลดค่าใช้จ่ายรวมของเครื่องจักร ความสามารถในการประหยัดค่าใช้จ่ายต่อชิ้นนี้ช่วยให้คุณมีความสามารถในการแข่งขันในตลาดของคุณได้มากขึ้น

กระบวนการตัดแบบเย็น จะช่วยให้ได้ชิ้นงานที่มีขอบเรียบและสะอาด ช่วยลดการประมวลผลขั้นที่สองได้ และยังสามารถตัดวัสดุแข็งและอ่อนได้ในกระบวนการเดียวกัน

นอกจากนี้ กระบวนการตัดวอเตอร์เจ็ท (Waterjet Flow Mach 200c) ยังมีความปลอดภัยสำหรับผู้ปฏิบัติงานและสิ่งแวดล้อม เนื่องจากใช้แค่น้ำหรือส่วนผสมที่มีฤทธิ์กัดกร่อนน้ำเท่านั้น จึงไม่ก่อให้เกิดควันหรือไอระเหยที่เป็นอันตราย อนุภาคฝุ่นที่พ่นออกมาจะถูกกักไว้ในน้ำและกรองออกอย่างปลอดภัย

เนื่องจากกระบวนการตัดด้วยวอเตอร์เจ็ท (Waterjet Flow Mach 200c) มีความยืดหยุ่นและมีความปลอดภัยสูง ทำให้เป็นที่นิยมในหลายอุตสาหกรรม เช่น อุตสาหกรรมการบินและอวกาศ การตัดด้วยวอเตอร์เจ็ทมีการใช้อย่างแพร่หลายในการผลิตชิ้นส่วนจากไทเทเนียม อลูมิเนียม และคอมโพสิตเพื่อให้ชิ้นส่วนเหล่านั้นตรงตามมาตรฐานความปลอดภัยและประสิทธิภาพที่เข้มงวด ฃ

สำหรับอุตสาหกรรมยานยนต์ จะช่วยในการผลิตชิ้นส่วนต่างๆ เช่น เฟือง , อุปกรณืจับยึด และชิ้นส่วนภายในรถยนต์ เพราะการตัดด้วยวอเตอร์เจ็ทมีความยืดหยุ่นสูง จึงช่วยให้สามารถปรับแต่งชิ้นส่วนให้ตรงตามความต้องการการออกแบบเฉพาะได้ จึงช่วยเพิ่มความสวยงามและฟังก์ชันของรถยนต์ได้มากขึ้น นอกจากนี้ยังใช้ในอุตสาหกรรมพลังงาน การแพทย์ อิเล็กทรอนิกส์ สถาปัตยกรรม อุตสาหกรรมเรือ อาหาร และ งานศิลปะ เป็นต้น

Article by: MEGATech & Siam Anankit Ltd., Part.<< Click Here