คอลัมน์นี้ MEGA Tech ขอนำเสนอ ซอฟต์แวร์ BySoft CAM และ Plant Manager หนึ่งในปัจจัยที่ช่วยให้โรงงานของคุณเป็น Smart Factory โดยซอฟต์แวร์จะช่วยให้การวางแผนและติดตามกระบวนการตัดและดัดด้วยเลเซอร์ทั้งหมดได้ทั้งแบบอัตโนมัติและสามารถกำหนดค่าได้เองตามความเหมาะสมกับชิ้นงาน

ในสภาพแวดล้อมการแปรรูปโลหะแผ่นที่ทันสมัย โซลูชันซอฟต์แวร์เปิดโอกาสให้ได้เปรียบในการแข่งขันที่ไม่เหมือนใคร ในเบื้องหลังการทำงานของขั้นตอนการตัด การดัด และระบบอัตโนมัติ ซอฟต์แวร์ประสิทธิภาพสูงจาก Bystronic รองรับข้อมูลทั้งหมดและเส้นทางการไหลของข้อมูล โดยการใช้งาน BySoft CAM และ Plant Manager ทำให้ Bystronic สามารถนำเสนอโซลูชันที่ช่วยอำนวยความสะดวกให้กับสภาพแวดล้อมการผลิตแบบเครือข่ายดิจิทัล ซึ่งจะช่วยแนะนำผู้ใช้ตั้งแต่ขั้นตอนการเข้ามาของวัตถุดิบจนถึงชิ้นส่วนผลิตสำเร็จที่ทำงานได้ด้วยขั้นตอนการทำงานที่รวดเร็วและมีประสิทธิภาพ

โดยการสร้างและคำนวณชิ้นงาน สร้างแผนการตัดและโปรแกรมดัดโค้ง วางแผนและตรวจสอบกระบวนการผลิต: การผลิตโลหะแผ่นสมัยใหม่จะไม่สามารถไปต่อได้ หากไม่มีซอฟต์แวร์ที่ทรงประสิทธิภาพสูง เช่น BySoft CAM

BySoft CAM ซึ่งมีฟังก์ชันที่หลากหลายและยังใช้งานง่าย ด้วยวิธีนี้ คุณจะสามารถรักษาไว้ภาพรวมการทำงานของระบบได้ ในขณะที่สามารถทำงานให้เสร็จอย่างรวดเร็ว ในราคาประหยัด และเชื่อถือได้ โดยการใช้ BySoft CAM – ทำให้เรื่องนี้เป็นเรื่องง่าย

การสร้างชิ้นงาน

BySoft CAM สนับสนุนการสร้างชิ้นงานของคุณ โดยนำเสนอชุดแพ็คเกจเสริม 3D-CAD อันทรงพลังสำหรับแพ็คเกจ 3D-CAD ที่ใช้งานอยู่ทั่วโลก ทาง BySoft CAM มีเครื่องมือที่คุณต้องการสำหรับการใช้งานเฉพาะ เพื่อการสื่อสารแนวคิดที่ชัดเจนเกี่ยวโมเดลที่ต้องการได้ทันที และใช้งานง่าย ดังนั้นคุณจึงสามารถสร้างโมเดล 3 มิติที่ถูกต้องของชิ้นงานที่จะผลิตได้อย่างรวดเร็วและมั่นใจ

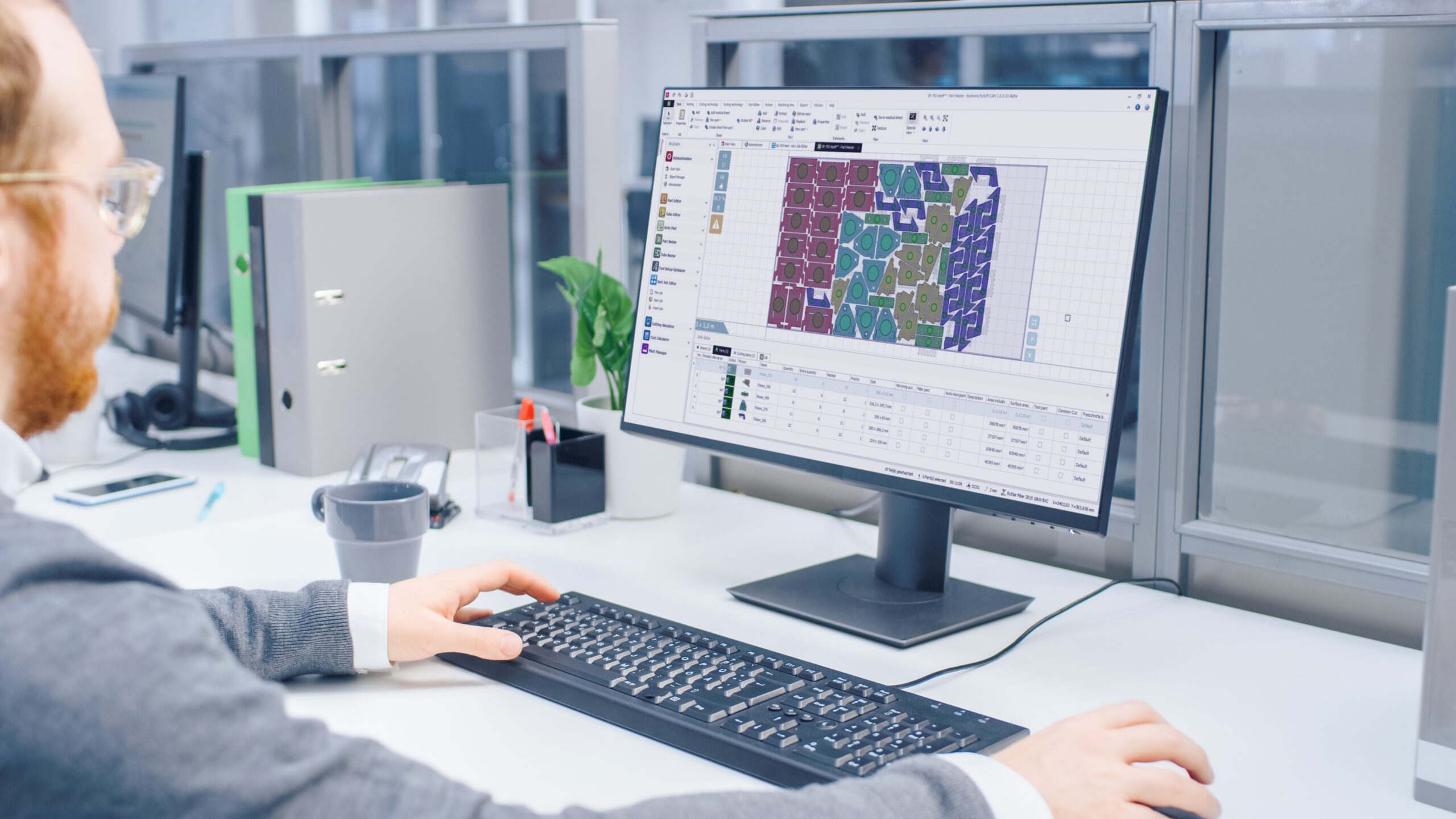

การสร้างแผนการตัด

BySoft CAM ช่วยให้แน่ใจว่าโลหะแผ่น ท่อ และเหล็กรูปพรรณ จะถูกใช้อย่างสมบูรณ์ และจัดวัสดุชิ้นงานเพื่อให้เหลือเศษตัดน้อยสุดเท่าที่เป็นไปได้ในทางเทคนิค ในการทำเช่นนี้ BySoft CAM มีฟังก์ชันมากมาย เช่น กระบวนการจัดวัสดุที่หลากหลาย ยิ่งไปกว่านั้น BySoft CAM ยังปรับกระบวนการตัดของคุณให้เหมาะสมและเลือกเทคโนโลยีการตัดที่เหมาะสมที่สุดโดยอัตโนมัติอีกด้วย

การสร้างแผนการดัด

ด้วย BySoft CAM คุณสามารถสร้างโปรแกรมดัดโค้งที่สมบูรณ์แบบได้ ลำดับการดัด ตำแหน่งระยะตัดด้านหลัง และแผนการใช้เครื่องมือจะถูกตรวจจับโดยอัตโนมัติ เพื่อให้กระบวนการดัดเริ่มเร็วขึ้น นอกจากนี้ BySoft CAM ยังสามารถจำลองลำดับการดัดและแสดงการชนที่อาจเกิดขึ้นได้โดยอัตโนมัติ ซึ่งช่วยให้มั่นใจได้ถึงความปลอดภัย ประหยัดเวลาและวัสดุมากยิ่งขึ้น รวมถึงวลดระยะเวลาในการทำงานของงานลงได้

จากการประกอบสู่กระบวนการผลิต

BySoft CAM ช่วยให้งานตัดและงานดัดเสร็จอย่างรวดเร็ว และใช้ความพยายามเพียงเล็กน้อย เนื่องจาก: คุณรักษาภาพรวมของกระบวนการผลิตและการตัดสินใจโดยใช้ข้อมูล ดังนั้นคุณจึงส่งมอบตรงเวลาและเงื่อนไขตามที่ต้องการ นี่คือวิธีที่ BySoft CAM รับประกันการทำงานที่เห็นได้อย่างชัดเจน

โมดูลต่างๆ

ตัด (Cut)

ด้วยโมดูลนี้ คุณสามารถนำเข้าและแก้ไขข้อมูล CAD ที่มีอยู่ได้ คุณสามารถสร้างแผนการตัดที่สมบูรณ์แบบสำหรับการแปรรูปโลหะแผ่นและวัสดุ 2D อื่นๆ

- คุณสามารถสร้างโปรแกรมตัดได้ทันทีเพราะ BySoft CAM มีโครงสร้างที่ชัดเจนและเปลี่ยนผู้ใช้งานที่มีประสบการณ์น้อยให้กลายเป็นผู้เชี่ยวชาญด้านการตั้งค่าโปรแกรมได้

- คุณจะลดต้นทุนชิ้นงานลง เนื่องจากวัตถุดิบถูกใช้จนหมด ในการทำเช่นนั้น BySoft CAM มีตัวเลือกที่ครอบคลุม เช่น กระบวนการจัดวัสดุเพื่อลดเศษวัสดุให้เหลือน้อยที่สุด

- ด้วยการกดปุ่ม BySoft CAM จะเลือกเทคโนโลยีการตัดที่ถูกต้องและใช้งานได้อย่างง่ายดาย

- ด้วยฟังก์ชันมากมาย BySoft CAM ให้กระบวนการที่เชื่อถือได้ คุณได้รับผลกำไรด้วยชิ้นงานที่ตัดได้อย่างสมบูรณ์แบบและอัตราการใช้งานเครื่องจักรที่สูง

- ตัวเลือกด้วย BySort: สามารถสร้างแผนการจัดเรียงโดยใช้ขั้นตอนอัตโนมัติสำหรับการเรียงซ้อนชิ้นส่วนของคุณให้เหมาะสมที่สุด

ดัด (Bend)

ด้วยโมดูลนี้ คุณสามารถจำลองชิ้นส่วนและนำเข้าและแก้ไขข้อมูล CAD ที่มีอยู่ได้ คุณสามารถสร้างโปรแกรมการคลี่และการดัดที่สมบูรณ์แบบได้

- คุณสามารถใช้ความสามารถของเครื่องพับโลหะได้อย่างครบถ้วน เนื่องจากชิ้นงานต่างๆ ไม่ได้ถูกตั้งโปรแกรมไว้ในเครื่องจักรอีกต่อไป แต่จะอยู่ใน BySoft CAM

- ข้อมูลเครื่องจักรและเครื่องมือที่เกี่ยวข้องทั้งหมดสำหรับเครื่องพับโลหะของคุณจะถูกเก็บไว้ใน BySoft CAM ดังนั้นคุณจึงทำการคลี่ที่สมบูรณ์แบบ โดยใช้ค่าเผื่อการดัดที่ถูกกำหนดโดยผู้เชี่ยวชาญ

- ด้วยการจำลองลำดับการดัดอย่างเต็มรูปแบบ คุณสามารถป้องกันการชนและข้อผิดพลาดที่มีค่าใช้จ่ายสูง

- คุณสามารถเตรียมงานได้รวดเร็วขึ้นเพราะ BySoft CAM ได้กำหนดและแนะนำลำดับการดัด ตำแหน่งระยะตัดด้านหลัง และแผนการใช้เครื่องมือ

- ปรับเวลาการตั้งค่าให้เหมาะสม เมื่อทำการผลิตชิ้นงานดัดหลายชิ้น โดย BySoft CAM จะสร้างและเสนอลำดับการผลิตชิ้นงานที่เหมาะสมที่สุด

ท่อ (Tube)

ด้วยโมดูลนี้ คุณสามารถสร้างชิ้นงานและนำเข้าและแก้ไขข้อมูล CAD ที่มีอยู่ได้ คุณสามารถสร้างแผนการตัดที่สมบูรณ์แบบสำหรับการประมวลผลท่อและเหล็กรูปพรรณ

- แม้แต่โปรแกรมตัดท่อและเหล็กรูปพรรณที่ซับซ้อนก็สามารถสร้างได้ในพริบตา เนื่องจาก BySoft CAM มีโครงสร้างที่ชัดเจนและเปลี่ยนผู้ใช้ที่มีประสบการณ์น้อยให้กลายเป็นผู้เชี่ยวชาญด้านการตั้งค่าโปรแกรม

- โดยการหมุนหน้าตัดและชิ้นงาน สิ่งเหล่านี้สามารถจัดเพื่อให้มีเศษวัสดุเหลือน้อยที่สุดได้อย่างมีประสิทธิภาพมากขึ้น เป็นใช้วัสดุอย่างเต็มที่และลดต้นทุนชิ้นงานลงอีก

- ด้วยการกดปุ่ม BySoft CAM จะเลือกเทคโนโลยีการตัดที่ถูกต้องและใช้งานได้อย่างง่ายดาย

- ด้วยฟังก์ชันมากมาย BySoft CAM ให้กระบวนการที่เชื่อถือได้ คุณได้รับผลกำไรด้วยชิ้นส่วนที่ตัดได้อย่างสมบูรณ์แบบและอัตราการใช้งานเครื่องจักรที่สูง

Plant Manager คืออะไร?

Plant Manager เป็นเครื่องมือพิเศษที่คุณสามารถใช้เพื่อวางแผนและติดตามกระบวนการตัดและดัดด้วยเลเซอร์ทั้งหมดได้ ทั้งแบบอัตโนมัติและแบบกำหนดค่าขึ้นเอง

Plant Manager สามารถทำงานอะไรได้บ้าง?

ระบบ ERP แต่ละระบบจะแบ่งออกเป็นวงจรการทำงานแต่ละรอบในห่วงโซ่การผลิต หนึ่งในวงจรเหล่านี้คือ การวางแผนทั่วไปของกระบวนการตัดและดัด ซึ่งจุดนี้ Plant Manager จะประเมินและปรับแต่งการวางแผนโดยอัตโนมัติ ด้วยวิธีนี้ ระบบจะบันทึกแต่ละขั้นตอนและเวลาที่ใช้ ทำให้ช่วยลดต้นทุนและขจัดแหล่งที่มาของข้อผิดพลาด นอกจากนี้ Plant Manager ยังเริ่มต้นและตรวจสอบการผลิตชิ้นงาน และให้ข้อมูลสถิติที่ครอบคลุมแก่คุณได้

การวางแผน

- Plant Manager จะดึงข้อมูลงานจากระบบ ERP หรือแหล่งงานอื่นๆ และเชื่อมโยงเข้ากับข้อมูล CAD

- Plant Manager จัดกลุ่มชิ้นงานตามประเภทของวัสดุ ความหนาของวัสดุ และตารางการทำงาน ตลอดจนการจัดประเภทตามหัวตัด หัวฉีดตัด และเครื่องจักร

- สร้างโปรแกรมการตัดและการดัดที่เหมาะสมที่สุด และใช้เทคโนโลยีการตัดที่เหมาะสม

- Plant Manager ช่วยลดเวลาการตั้งค่าด้วยการวางแผนที่เหมาะสมที่สุดสำหรับเครื่องดัด

การผลิต

- Plant Manager จะจัดการและควบคุมงานเครื่องจักรทั้งหมด รวมถึงงานเร่งด่วนของคุณ

- มีแผนสำหรับช่วงเวลาการบำรุงรักษาและกะการทำงาน

- Plant Manager ตรวจสอบและแสดงภาพกระบวนการบนระบบเครื่องจักรแต่ละระบบและสภาพของระบบดังกล่าว

- Plant Manager ให้ภาพรวมการผลิตที่สมบูรณ์แก่คุณ

สถิติ

- Plant Manager จะประเมินเครื่องจักรและข้อมูลงานที่เกี่ยวข้องทั้งหมดสำหรับคุณ และให้ข้อมูลสถิติที่เกี่ยวข้องแก่คุณ

- หากมีเหตุการณ์ที่กำหนดไว้เกิดขึ้น Plant Manager จะส่งอีเมลที่เกี่ยวข้องถึงคุณ

ผลประโยชน์ที่ลูกค้าได้รับ

- คุณสามารถผลิตชิ้นงานได้รวดเร็วขึ้น ด้วยต้นทุนที่ต่ำลง และใช้แรงน้อยลง

- กระบวนการผลิตของคุณจะทำงานได้อย่างน่าเชื่อถือมากขึ้น เนื่องจากไม่จำเป็นต้องป้อนข้อมูลด้วยตนเองอีกต่อไป และเครื่องจักรจะได้รับการดูแลอย่างสม่ำเสมอ

- คุณยังคงรักษาภาพรวมที่สมบูรณ์ของการผลิตและสภาพของระบบเครื่องจักรของคุณไว้ได้

- คุณจะได้รับข้อมูล ซึ่งช่วยให้คุณสามารถเพิ่มประสิทธิภาพการผลิตของคุณต่อไปได้

Article by: Bystronic (Thailand) Co., Ltd. & MEGATech