Article by: Bystronic & Procurement Centre (Thailand) Co., Ltd.

ความแม่นยำและความเที่ยงตรงสูง คือ มาตรฐานสำคัญในการเลือกสรรเครื่องพับโลหะในกระบวนการผลิต เนื่องด้วยความหลากหลายของชิ้นงานทั้ง ขนาด ความหนาของแผ่นวัสดุ ความยาวในการพับ ความรวดเร็วในกระบวนการทำงาน เป็นต้น โดยที่ระบบ Bending Cell จาก Bystronic และ Haco’s PressMaster Series เต็มเปี่ยมด้วยประสิทธิภาพสำหรับงานพับในการสร้างชิ้นงานคุณภาพสูงในยุคของการผลิต 4.0 ได้เป็นอย่างดี

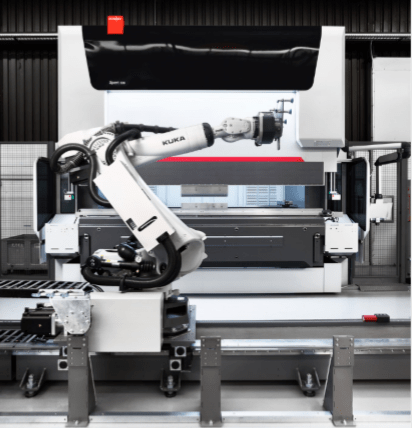

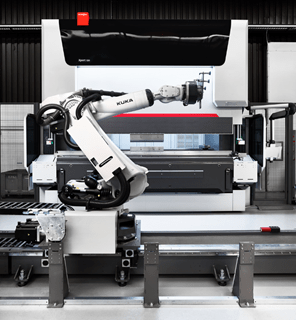

Bending Cell: ระบบพับโลหะอัตโนมัติเต็มรูปแบบ

Bystronic ปรับปรุงประสิทธิภาพของเครื่องพับโลหะ Xpert Pro ให้เป็นระบบพับโลหะอัตโนมัติเต็มรูปแบบ Bending Cell ซึ่งช่วยให้ผู้ใช้สามารถทำงานพับโลหะจำนวนมาก รวมถึงปรับการทำงานตามปริมาณการพับได้อย่างมีประสิทธิภาพและไม่มีข้อผิดพลาด จนทำให้ระบบพับโลหะอัตโนมัติเต็มรูปแบบ Bending Cell ได้รับรางวัล MM Award จากงาน EuroBLECH 2018

Bending Cell สามารถพับโลหะแผ่นได้ด้วยระบบการทำงานอัตโนมัติเต็มรูปแบบ ซึ่งเป็นผลมาจากการที่ Bystronic ปรับปรุงเครื่องพับโลหะรุ่นสูงสุดอย่าง Xpert Pro โดยการเพิ่มระบบการทำงานด้วยหุ่นยนต์ที่รวดเร็วและคล่องตัว หุ่นยนต์ระบบ 7 แกนจะทำหน้าที่หยิบชิ้นงานโลหะแผ่นที่ต้องการพับ นำไปวางลงบนเครื่อง Xpert Pro ด้วยความเที่ยงตรงสูงเพื่อทำการพับ จากนั้น นำชิ้นงานที่ได้มาคัดแยกตามคำสั่งงาน ระบบพับโลหะ Bending Cell รองรับน้ำหนักชิ้นงานโลหะแผ่นได้สูงสุด 270 กิโลกรัม

ระบบหุ่นยนต์ความเที่ยงตรงสูงยังสามารถเลือกเครื่องมือพับโลหะที่เหมาะกับงานได้โดยอัตโนมัติ เนื่องจาก Bystronic มีการติดตั้งแม็กกาซีนเครื่องมือให้กับระบบ Bending Cell ทำให้มีเครื่องมือพับที่ต้องการพร้อมสำหรับการใช้งานตลอดเวลา นอกจากนี้ ระบบ Bending Cell ยังมีแรงกดสูงสุดถึง 320 ตัน ทำให้ระบบอัตโนมัตินี้รองรับการใช้งานได้กับผลิตภัณฑ์โลหะแผ่นหลากหลายรูปแบบ ระบบ Bending Cell เหมาะเป็นพิเศษสำหรับงานผลิตเป็นจำนวนมากที่ต้องการประสิทธิภาพการทำงานสูง รวมถึง งานจำนวนน้อยที่ต้องเปลี่ยนรูปแบบการทำงานบ่อยๆ ระบบ Bending Cell จาก Bystronic ได้รับรางวัล MM Award ในงาน EuroBLECH 2018 โดยคณะกรรมการผู้เชี่ยวชาญ ซึ่งประกอบด้วยด้วยบรรณาธิการจากนิตยสาร “blechnet” และ “MM Maschinenmarkt” ต่างก็ประทับใจเป็นพิเศษกับแนวคิดการออกแบบของระบบพับโลหะอัตโนมัตินี้ คณะกรรมการพูดถึงจุดเด่นของระบบ Bending Cell ว่า “ระบบนี้ช่วยให้สามารถทำงานต่างๆ ได้แบบอัตโนมัติจากเมื่อก่อนที่เคยต้องใช้แรงงานคน ไม่ว่าจะเป็นการเปลี่ยนเครื่องมือหรือการปรับตั้งเครื่องใหม่เมื่อเปลี่ยนรูปแบบงาน ซึ่งทำให้การผลิตตลอด 24 ชั่วโมง 7 วันต่อสัปดาห์โดยไม่ต้องใช้คนควบคุมกลายเป็นเรื่องที่เป็นไปได้ขึ้นมาจริงๆ”

Intelligent System for Precise Bending

เครื่องพับ ซีเอ็นซี Haco’s PressMaster ซีรีย์ มีคุณสมบัติการทำงานขนาดสูง ทั้งสเปค, คอนโทรลคุมเครื่องจักร, ซอฟท์แวร์, ระบบรักษาความปลอดภัย และเทคโนโลยีทูลลิ่งที่ติดตั้งใบพับได้เร็ว ความแม่นยำสูง และเพิ่มประสิทธิภาพการผลิต

ที่สุดของสเปคคือ Multi Touch FastBEND-3D MT Premium control ซอฟท์แวร์ที่เลือกทูลลิ่งพาร์ต ให้ผู้ใช้ ระหว่างออกแบบชิ้นงานได้เลยโดยอัตโนมัติ และคำนวณลำดับการพับให้อีกด้วย

ความเที่ยงตรงของการพับถูกการันตีโดย

New Standard Tooling System ซึ่งให้ค่าความเที่ยงตรงที่สุดและคงทนที่สุด การใส่ใบพับในแนวตั้งพร้อมกับการยึดจับด้วยตัวเอง และเช็คความแน่นด้วยตัวเอง การันตีความรวดเร็วในการติดตั้งใบพับ ตัวเครื่องยังมีออปชั่น “Smart Tool Locator” ระบบซึ่งสามารถชี้แนะ ตรวจสอบตำแหน่งของใบพับ ที่ติดอยู่ระหว่างการพับได้

ระบบวัดองศาโดยอัตโนมัติและแก้องศาการพับโดยอัตโนมัติ

Haco PressMaster Series มีระบบนี้สองทางเลือก

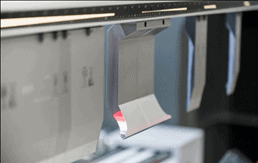

1) Alfa-F Angle Measurement System

ระบบนี้ประกอบด้วยลำแสงเลเซอร์ สองทาง และกล้องตรวจจับสองทางสองตัว ทั้งสองฝั่งของชิ้นงาน ด้วยระบบนี้จะมั่นใจได้ว่าแต่ละองศาการพับจะพับงานได้แม่นยำตั้งแต่ชิ้นแรก โดยคนพับไม่ต้องมาคอยวัดองศาด้วยมือ และป้องกันผลกระทบจากชิ้นงานดีดกลับ และหรือความคลาดเคลื่อนในค่าความหนา และค่าต่างๆ ที่เซทไว้ในเครื่อง

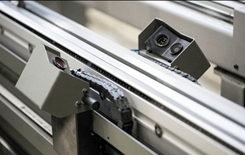

2) Optical Light Guard Iris Plus with Active Angle Control

ด้วยระบบ Active Angle Control การควบคุมองศาด้วยแสงเลเซอร์ที่ปลอดภัย IRIS Plus การันตีความปลอดภัยของการทำงานโดยคุมอุปกรณ์รอบใบพับทั้งหมด หยุดการทำงานทั้งหมดถ้าหากมีการลงของใบพับที่เร็วหรือหนักเกินไป แสงเลเซอร์จะตรวจเจอความเสี่ยงทั้งหมดในบริเวณที่ได้รับการปกป้อง

ระบบ IRIS Plus เซฟตี้นี้ประกอบด้วยเครื่องส่งเลเซอร์ และตัวรับที่ติดอยู่ที่ใบพับด้านบน แต่ละรุ่นจะมาพร้อมกับกล้องดิจิตอลความเร็วสูงและระบบประมวลผลรูปภาพ ภาพที่เก็บไว้ในระบบ IRIS Plus จะประมวลผลเพื่อชดเชยกับค่าการดีดกลับของชิ้นงานที่อาจเกิดขึ้นโดยไม่คาดหมาย ด้วยระบบ Active Angle Control นี้การพับชิ้นงานแต่ละชิ้นจะได้รับค่าองศาที่ถูกต้องตั้งแต่ชิ้นแรกจนชิ้นสุดท้าย

การมีเทคโนโลยีทั้งสองข้างต้นนี้ ทำให้เกิดขั้นตอนการตัดพับที่ไม่เคยมีมาก่อนในการลดเวลาการติดตั้ง และความถูกต้องของชิ้นงานที่ +/- 0.1มิลลิเมตร และความแม่นยำขององศาที่ +/-20