แบรนด์เครื่องจักรจากจีนได้รับการยอมรับในตลาดเกิดใหม่ เนื่องจากราคาที่แข่งขันได้และคุณภาพไม่เป็นรอง แม้ว่าผลิตภัณฑ์ระดับไฮเอนด์ยังครองตลาดโดยผู้ผลิตจากยุโรปหรือญี่ปุ่น แต่ผู้เล่นจากจีนกำลังบุกเบิกตลาดโดยนำเสนอตัวเลือกในราคาจับต้องได้และเน้นลูกค้าเฉพาะกลุ่ม MEGA Tech เจาะลึกเครื่องพับโลหะ CNC รุ่น CHD Series จาก Shenglong ซึ่งเปิดตัวในประเทศไทยเมื่อเร็วๆนี้โดย บริษัท รีไฟน์เม้นท์ แมชชีนเนอรี่ จำกัด

การแปรรูปโลหะแผ่นยังมีความต้องการสูง

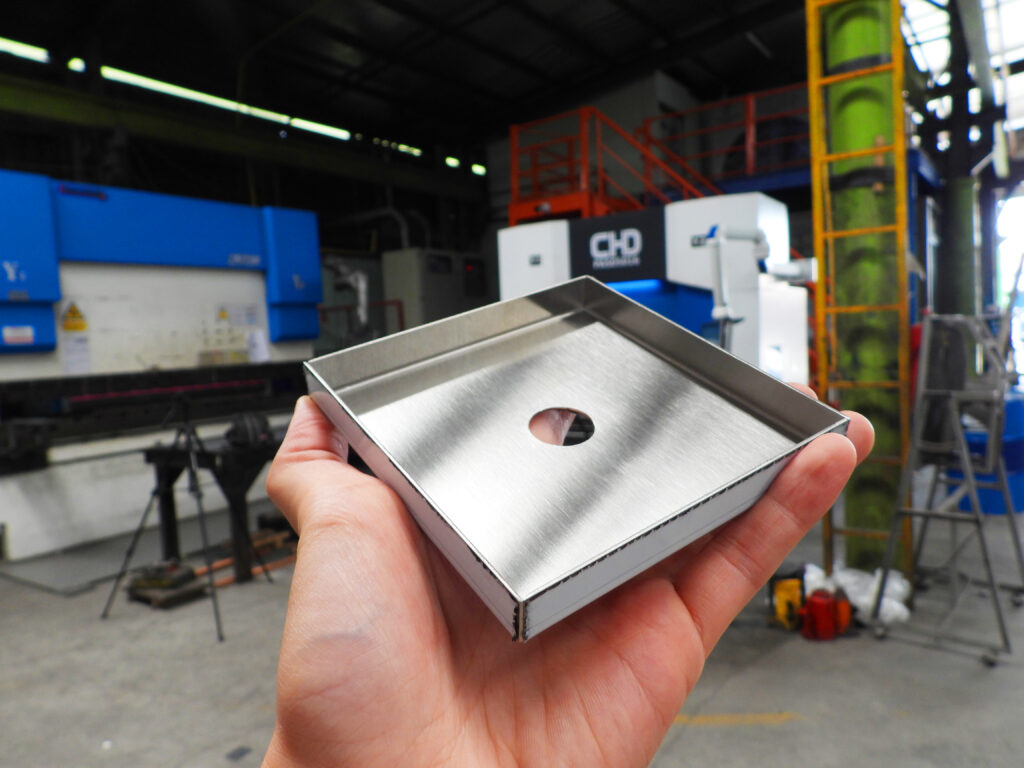

แม้ว่าจะมีอุปสรรคทางเศรษฐกิจบางประการ แต่ความต้องการชิ้นส่วนแปรรูปแผ่นโลหะของไทยยังคงเติบโต โดยเฉพาะในภาคอุตสาหกรรมยานยนต์และเครื่องใช้ไฟฟ้า ด้วยเหตุนี้ เครื่องพับโลหะจึงยังคงเป็นที่ต้องการของผู้ผลิตทั้งรายเดิมและสตาร์ทอัพหน้าใหม่

หนึ่งเครื่องจักรแต่หลากหลายชิ้นส่วนจากผู้ผลิตระดับโลก

นี่คือแบรนด์จีนที่มีปรัชญาการออกแบบที่เป็นเอกลักษณ์ CHD Series จาก Shenglong สร้างขึ้นโดยใช้ชิ้นส่วนและส่วนประกอบคุณภาพสูงจากผู้ผลิตแบรนด์ชั้นนำระดับโลก แนวทางนี้ชี้ให้เห็นถึงการเน้นด้านความน่าเชื่อถือ ประสิทธิภาพ และอายุการใช้งานของเครื่องจักร เนื่องจากส่วนประกอบแต่ละชิ้นได้รับการคัดสรรค์ตามความเป็นเลิศในหมวดหมู่ของมัน ซึ่งเครื่องพับโลหะไฮดรอลิก CHD Series จาก Shenglong สร้างขึ้นโดยใช้ชิ้นส่วนหรือโมดูลแยกชิ้นคุณภาพสูง ส่วนประกอบต่างๆ ได้รับการคัดเลือกจากซัพพลายเออร์จากทั่วโลก รวมถึงสหรัฐอเมริกา อิตาลี ไต้หวัน และบริษัทชั้นนำในประเทศของจีน

โครงสร้างและคุณสมบัติเด่น

เครื่องพับโลหะไฮดรอลิก CNC แบบซิงโครนัส รุ่น CHD Series จาก Shenglong ติดตั้งระบบไฟฟ้าไฮดรอลิกของ Rexrow การควบคุมวาล์วเซอร์โวตามสัดส่วนการซิงโครไนซ์ของกระบอกสูบคู่ ก็นำเข้าจากแบรนด์เครื่องพับดัดโลหะ CNC ชั้นนำของโลกเช่นกัน เพื่อสร้างระบบควบคุมแบบซิงโครนัสลูปปิดเต็มรูปแบบที่ให้ความแม่นยำและการทำงานประสิทธิภาพสูง สามารถควบคุมช่วงบวกและลบของความแม่นยำในการวางตำแหน่งที่ 0.02 มม. ความแม่นยำในการวางตำแหน่งซ้ำที่ 0.01 มม. และความแม่นยำขององศามุมดัดที่บวกลบไม่เกิน 0.5 องศา

ชิ้นส่วนเครื่องจักร

โครงสร้างที่เคลื่อนขึ้นของเครื่องจักรได้รับการออกและประกอบเพื่อให้มีความมั่นคงและเกิดเสียงรบกวนต่ำ ชิ้นส่วนเครื่องจักรทั้งหมดได้รับการออกแบบและผลิตโดยใช้การเชื่อมไฟฟ้าและผ่านกระบวนการอบอ่อนเพื่อลดความเครียดและปรับปรุงคุณสมบัติทางกลของโลหะ จึงทำให้เพิ่มความแข็งแกร่งและความสม่ำเสมอของประสิทธิภาพการทำงานของเครื่องจักร ชิ้นส่วนเจาะและกลึงขนาดใหญ่ถูกนำเข้ามาเพื่อให้แน่ใจว่าพื้นผิวการกลึงแต่ละพื้นผิวมีความขนานและตั้งฉากสูงสุด สำหรับอุปกรณ์ชดเชยแบบคู่ สไลเดอร์ด้านบนมีการติดตั้งระบบชดเชยการเบี่ยงเบนของลิ่มเฉียง และโต๊ะด้านล่างก็มีระบบชดเชยเชิงกลเพื่อให้ไม่ให้เกิดจุดอับสำหรับการชดเชยความผิดพลาดตลอดแนว

ชิ้นส่วนชุดแม่พิมพ์ (Dies)

มีชุดแม่พิมพ์ด้านบนมาตรฐาน และแม่พิมพ์ขนาดความยาวต่างๆ ที่สามารถประกอบแม่พิมพ์ด้านบนให้ได้ความกว้างที่ตรงตามความต้องการของชิ้นงานขนาดพิเศษ แม่พิมพ์ด้านบนวัดความสูงรวมได้ 150 มม. สำหรับแม่พิมพ์ด้านล่าง มีชุดแม่พิมพ์ด้านล่างมาตรฐานให้ และสามารถปรับแต่งขนาดของร่อง V ได้ตามความต้องการของลูกค้า

ชุดควบคุม

เครื่องพับโลหะไฮดรอลิก CNC ถูกควบคุมโดยระบบคอมพิวเตอร์ที่ซับซ้อนซึ่งแปลคำสั่งและจัดการการเคลื่อนไหวของเครื่องจักรเพื่อการพับดัดที่แม่นยำและเป็นอัตโนมัติ ระบบควบคุมหรือตัวควบคุม CNC ช่วยให้ผู้ปฏิบัติงานสามารถตั้งโปรแกรมลำดับการดัด จัดเก็บข้อมูล และตรวจสอบประสิทธิภาพของเครื่องจักรได้

CHD Series จาก Shenglong ใช้ชุดควบคุมจาก Syntec ผู้นำด้านอุตสาหกรรมที่มีชื่อเสียงของไต้หวันที่มีส่วนร่วมในการวิจัยและพัฒนาเทคโนโลยีซอฟต์แวร์และฮาร์ดแวร์ของตัวควบคุมเครื่องจักรกล โดยเน้นในด้านการควบคุมการเคลื่อนไหว ตัวควบคุมนี้รับประกันประสิทธิภาพของเครื่องจักร นอกจากนี้ CHD Series จาก Shenglong ยังใช้อุปกรณ์และชิ้นส่วนไฟฟ้าจาก Schneider Electric ซึ่งเป็นผู้นำระดับโลกด้านการจัดการพลังงานและระบบอัตโนมัติ

ผลิตภัณฑ์และบริการที่เชื่อถือได้

Refinement Machinery เป็นที่รู้จักในด้านการจัดหาเครื่องจักรคุณภาพดีในราคาที่เป็นมิตร ความเชี่ยวชาญด้านการซ่อมเครื่องจักร โดยเฉพาะเครื่องจักร CNC นั้นไม่เป็นรองใคร บริษัทฯนำเสนอบริการที่ครอบคลุม รวมถึงการซ่อมแซมฉุกเฉินและการสร้างใหม่ทั้งหมด โดยเน้นที่ความพึงพอใจของลูกค้า

เครื่องพับโลหะไฮดรอลิก CNC แบบซิงโครนัสไฟฟ้าไฮดรอลิก CHD Series จาก Shenglong เป็นอีกตัวอย่างหนึ่งที่มอบโอกาสให้กับผู้ผลิตในประเทศไทย ทั้งผู้เล่นเดิมและรายใหม่ในธุรกิจแปรรูปโลหะแผ่น สามารถจัดหาเครื่องจักรที่ราคาไม่แพงแต่เชื่อถือได้ ซึ่งช่วยให้สามารถแข่งขันได้พร้อมผลตอบแทนจากการลงทุนที่รวดเร็ว

Article by: MEGATech & REFINEMENT MACHINERY CO.,LTD << Click Here