การผลิตสินค้าในยุคสมัยใหม่ ต้องการระบบการพับที่มีความแม่นยำสูงและมีความเก่งกาจ งานพับโลหะแผ่นอยู่ในขั้นตอนการผลิต ผลิตภัณฑ์ที่หลากหลาย และต้องการความแม่นยำของวัสดุและองศาของการพับ มุมองศาที่ถูกต้องจะทำให้การทำงานง่ายขึ้นในแต่ละเสตปของการผลิตชิ้นงาน ลดความเสี่ยงที่ชิ้นงานจะผิดสเปก ทำให้ลูกค้าพึงพอใจในผลงาน เพิ่มประสิทธิภาพการผลิต สูญเสียวัตถุดิบที่ต้องทิ้งน้อย และลดต้นทุน

ระบบวัดองศาโดยอัตโนมัติ และ ระบบแก้ไของศาการพับโดยอัตโนมัติ

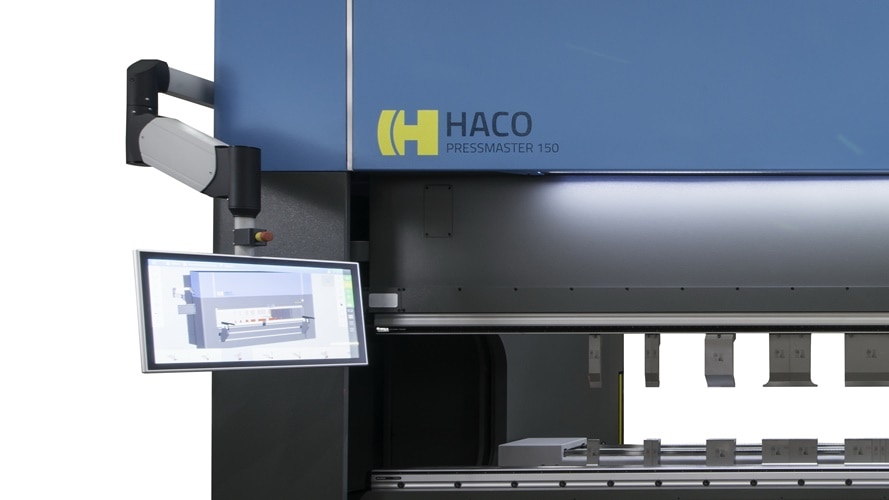

HACO ผู้เชี่ยวชาญด้าน การตัดพับ โลหะ จากประเทศเบลเยี่ยม ได้ออกแบบระบบที่ทำให้ปัญหานี้เป็นเรื่องง่ายดาย เครื่องพับ HACO คิดค้นระบบที่ชื่อ IRIS (Integrated Real Time Image System) ระบบอัตโนมัติ ที่จะวัดองศาของการพับจาก HACO โดยใช้เครื่องหมายทางการค้าว่า IRIS PLUS หรือ ALFA-F ซึ่งจะมีสเปกต่างกันไปตามชนิด และความยาวของเครื่องพับนั้นๆ สั้นๆ ระบบของ HACO มีความแม่นยำในการตั้งองศาการพับสูง คำนวณแรงดีดกลับของการพับในแต่ละครั้ง คำนวณความลึกของการพับเพื่อให้ถึงองศาที่ตั้งไว้

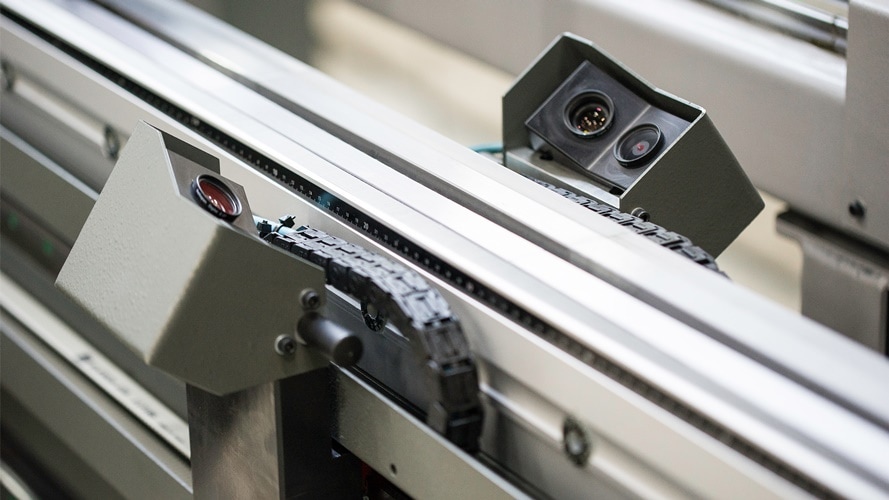

![]() The IRIS Plus จะวัดมุมองศาของแผ่นเหล็กนั้น และตรวจสอบกับโปรแกรมการพับ ระบบประกอบด้วย กล้องเซนเซอร์ 2 ตัว เลเซอร์อ่านค่า และตัวรับยิงแสงไปในทิศทางที่ใบพับทั้งสองด้าน ระหว่างการพับ ตัวรับแสงจะคำนวณเส้นแสดงรูปร่าง จากเส้นแสดงรูปร่าง/แสงเงานี้ วงจรจะคำนวณองศาของชิ้นงานผ่านอัลกอริทึ่มและเปรียบเทียบค่านี้กับค่าที่เราต้องการในโปรแกรมการพับ ถ้าไม่ตรงกัน ระบบอัตโนมัติจะปรับค่าให้ตรงกันและส่งสัญญาณไปคอนโทรลเลอร์เครื่องพับ เพื่อเปลี่ยนค่าพารามิเตอร์ขององศาให้ถูกต้อง

The IRIS Plus จะวัดมุมองศาของแผ่นเหล็กนั้น และตรวจสอบกับโปรแกรมการพับ ระบบประกอบด้วย กล้องเซนเซอร์ 2 ตัว เลเซอร์อ่านค่า และตัวรับยิงแสงไปในทิศทางที่ใบพับทั้งสองด้าน ระหว่างการพับ ตัวรับแสงจะคำนวณเส้นแสดงรูปร่าง จากเส้นแสดงรูปร่าง/แสงเงานี้ วงจรจะคำนวณองศาของชิ้นงานผ่านอัลกอริทึ่มและเปรียบเทียบค่านี้กับค่าที่เราต้องการในโปรแกรมการพับ ถ้าไม่ตรงกัน ระบบอัตโนมัติจะปรับค่าให้ตรงกันและส่งสัญญาณไปคอนโทรลเลอร์เครื่องพับ เพื่อเปลี่ยนค่าพารามิเตอร์ขององศาให้ถูกต้อง

เป็นเพราะการตั้งค่าของ ระบบตั้งองศาอัตโนมัติ ระบบผูกติดอยู่กับลำแสงเลเซอร์ มันไม่มีกลไกทางแมกคานิคที่จะสัมผัส กับชิ้นงานหรือใบพับของเครื่องพับ ระบบ IRIS Plus มีพาร์ตที่เคลื่อนไหวน้อยมาก และง่ายในการติดตั้งและตั้งค่าเริ่มต้น นี่จะทำให้มั่นใจว่าระบบจะทนทานใช้งานได้นานและไม่รบกวนการติดทูลลิ่ง

HACO for Impressive Performances

คุณประโยชน์หลักของระบบ IRIS Plus คือมันเป็นระบบที่ รวมทั้งการตรวจจับเพื่อความปลอดภัย และระบบที่ช่วยการผลิตให้เร็วขึ้น ด้วยการวัดองศาที่แม่นยำในการพับ ตั้งแต่ V-die เปิด ( 6-35 มิลลิเมตร, สำหรับ Single V’s เท่านั้น ) เนื่องจากการระบบติดตั้งที่ชาญฉลาดมันไม่มีทางที่ใบพับจะปะทะกับชิ้นงาน

นอกจาก ระบบ IRIS Plus system, HACO ยังมีระบบอัตโนมัติในการวัดมุม ALFA-F ซึ่งประกอบด้วยลำแสงเลเซอร์ 2 กล้อง ทั้งสองฝั่งของชิ้นงาน เหมาะกับหน้ากว้างของ V-Die หลายขนาด (6-100 mm, เฉพาะ Single V’s ) มันทำให้ผู้ใช้ยิ่งได้ความเอนกประสงค์มากขึ้น ได้ชิ้นงานแม่นยำขึ้น และทำชิ้นงานที่เป็นสามมิติได้ยอดเยี่ยม ประหยัดเนื้อที่สำหรับผู้คุมเครื่องและชิ้นงานได้รับการการันตี มั่นใจได้แม้เมื่อต้องรับงานหนัก