กระแสความนิยมของเทคโนโลยี Waterjet

ผู้ประกอบการมักต้องการลงทุนด้านเทคโนโลยีต่างๆ ที่จะช่วยส่งเสริมให้ธุรกิจเกิดความคล่องตัวได้ดียิ่งขึ้น จึงส่งผลให้เทคโนโลยีวอเตอร์เจ็ท waterjet เครื่องจักรตัดโลหะแผ่นด้วยพลังน้ำแรงดันสูงเป็นที่ได้รับความสนใจมากขึ้น โดยเทคโนโลยีวอเตอร์เจ็ท waterjet มีการพัฒนาในเรื่องของความเร็วและความแม่นยำที่มากขึ้น อีกทั้งมีราคาที่ไม่สูงนัก ผู้ประกอบการในโรงงานส่วนใหญ่ค้นพบว่ากระบวนการตัดชิ้นงานที่รวดเร็วยิ่งขึ้นจะให้ปริมาณงานที่เพิ่มขึ้น, ความแม่นยำของกระบวนการตัดที่มากขึ้นจะทำให้สามารถนำไปปรับใช้ได้ตรงกับความต้องการมากยิ่งขึ้น และต้นทุนของการดำเนินการที่ต่ำลงจะส่งผลให้ผลตอบแทนจากการลงทุนดีขึ้น

กระบวนการตัดชิ้นงานที่ให้คุณภาพและมีความแม่นยำสูง

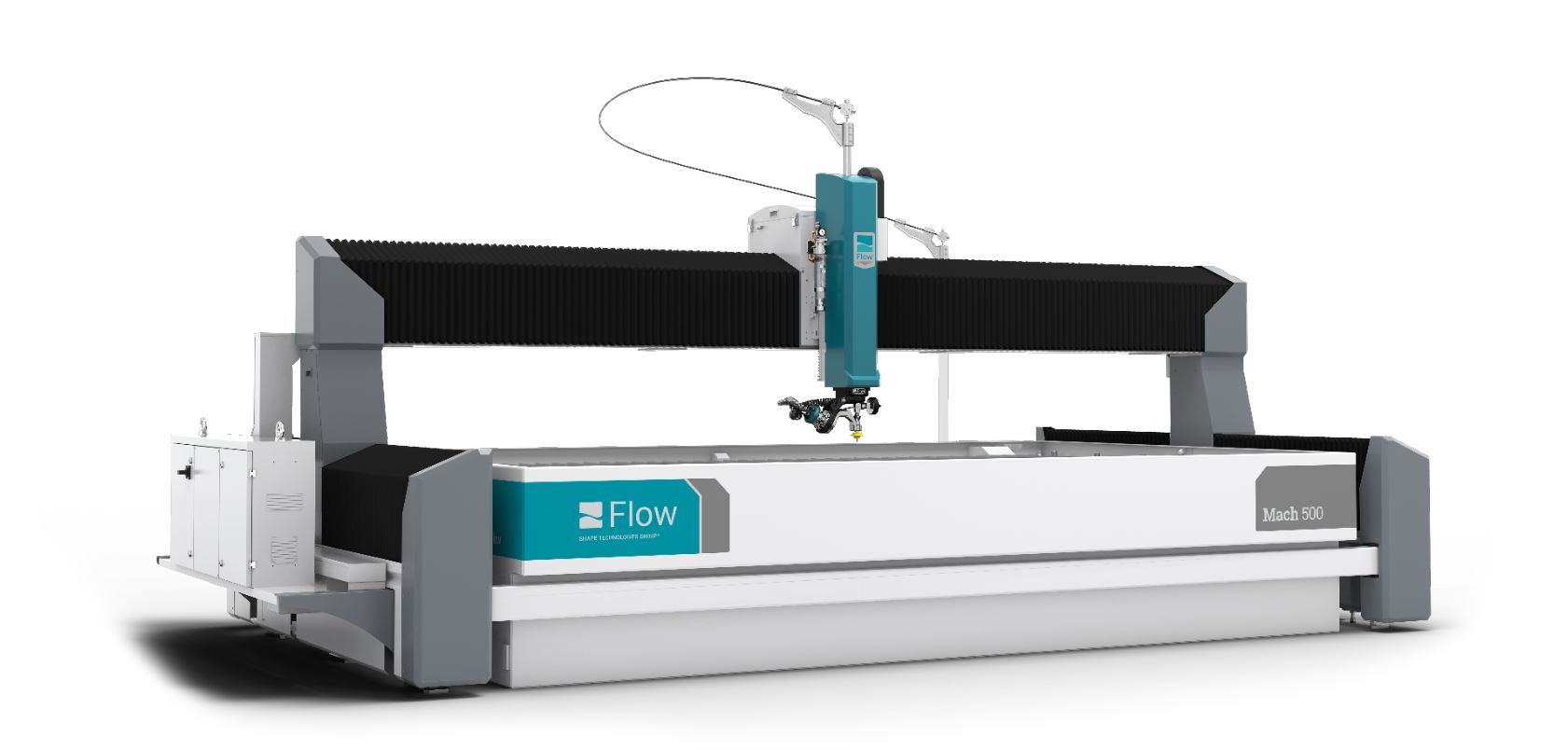

จากกระบวนการตัดชิ้นงานด้วยเครื่องตัดโลหะแผ่นด้วยพลังน้ำแรงดันสูง Water Jet Cutting ซึ่งไม่สามารถหลีกเลี่ยงรอยตัดที่เกิดจากแรงเฉื่อยของลำน้ำแรงดันสูง (stream lag) ที่ทำให้ผิวตัดเอียง หรือเป็นเตเปอร์ (taper) ได้ ส่งผลให้บริษัท Flow ซึ่งมีความเชี่ยวชาญและมีนวัตกรรมวอเตอร์เจ็ท Water Jet มากมาย ได้มีการพัฒนา Dynamic Waterjet® ขึ้น โดยมีการชดเชยข้อผิดพลาดและเพิ่มประสิทธิภาพกระบวนการตัดชิ้นงานให้มีความเร็วและแม่นยำยิ่งขึ้น, เศษโลหะลดลง, เพิ่มความสามารถในกระบวนการผลิตและนำไปสู่ผลตอบแทนการลงทุน (ROI) ที่สูงขึ้น

จากอุตสาหกรรมที่หลากหลาย บริษัท Flow จึงได้มีการเสนอกระบวนการตัดชิ้นงานด้วยเครื่องตัดโลหะแผ่นด้วยพลังน้ำแรงดันสูง Water Jet Cutting ที่หลากหลายรูปแบบ โดยยึดหลักของการที่ลูกค้าสามารถซื้อหาในราคาที่จับต้องได้ และใช้เทคโนโลยี 5 แกน ที่มีระบบใช้งานง่าย อีกทั้งยังมีการพัฒนาการใช้งานให้เหมาะกับงานตัดแบบ 3 มิติ ด้วย Dynamic XD นอกจากนั้น บริษัท Flow ยังมีการพัฒนาอุปกรณ์สำหรับการตรวจจับความสูง (height sensing) และปรับระดับหัวตัดตามโครงสร้าง (contour following) เพื่อให้หัวตัดสามารถใช้งานได้อย่างมีประสิทธิภาพสูงสุด

ระบบซอฟต์แวร์ที่เป็นมิตรต่อผู้ใช้งาน

ระบบซอฟต์แวร์ถือเป็นส่วนประกอบที่จำเป็นสูงสุดสำหรับกระบวนการตัดด้วยเครื่องตัดโลหะแผ่นด้วยพลังน้ำแรงดันสูง Water Jet Cutting เพราะเป็นส่วนทำให้กระบวนการตัดชิ้นงานเป็นไปอย่างมีคุณภาพและมีความแม่นยำสูง ซึ่งจะทำให้เกิดความสามารถในการผลิตโดยรวมเพิ่มขึ้น โดยวิธีการใช้งานของ FlowXpert software นั้นใช้งานได้ง่ายและมีความครอบคลุมกับงานตัดหลายรูปแบบ รวมทั้งสามารถใช้ได้ในกระบวนการตัดที่มีการขึ้นรูปในรูปแบบ 3 มิติ (3D CAD)

ปัจจัยหลักที่สำคัญที่สุดในการสร้างวิวัฒนาการวอเตอร์เจ็ท Waterjet คือ การใช้ซอฟต์แวร์ในระบบการทำงาน โดยบริษัท Flow ได้ใช้หลักการออกแบบซอฟต์แวร์ที่ทันสมัยด้วยการพัฒนาให้ใช้งานง่ายยิ่งขึ้น แม้จะไม่มีทักษะความชำนาญเฉพาะด้านมากนักก็ตาม และยังมีระบบการทำงานในรูปแบบอัตโนมัติที่ให้ความยืดหยุ่นมากยิ่งขึ้น ซึ่งถือเป็นการเปิดโอกาสใหม่ในการผสมผสานเทคโนโลยีวอเตอร์เจ็ท Waterjet ให้เข้ากับสภาพแวดล้อมในกระบวนการผลิตแบบ multi-process เพื่อนำคุณค่าและคุณประโยชน์ของเทคโนโลยีวอเตอร์เจ็ท Waterjet เข้าไปสู่ตลาดอุตสาหกรรมใหม่ ๆ เพิ่มมากขึ้น

อนาคตอันก้าวไกลของเครื่องตัดโลหะแผ่นด้วยพลังน้ำแรงดันสูง Water Jet

นอกจากนี้ อุตสาหกรรมยังมีการปรับเปลี่ยนรูปแบบกระบวนการซ่อมบำรุงไปสู่รูปแบบการซ่อมบำรุงเชิงป้องกัน (Preventative Maintenance: PM) มากยิ่งขึ้น ซึ่งกระบวนการซ่อมบำรุงที่เชื่อถือได้และคาดการณ์ได้แม่นยำ จะช่วยส่งเสริมให้เครื่องจักรทำงานได้อย่างเต็มประสิทธิภาพสูงสุด ซึ่งเป็นการตอบโจทย์ความต้องการของผู้ประกอบการในการเพิ่มประสิทธิภาพกระบวนการผลิตโดยรวมให้ดียิ่งขึ้น

บริษัท Flow มุ่งเน้นความสำคัญของการพัฒนาระบบซอฟต์แวร์และระบบการเชื่อมต่อ เป็นปัจจัยหลัก โดยเครื่องจักรที่ถูกเชื่อมต่อจะให้ข้อมูลตั้งแต่ช่วงการซ่อมบำรุงเชิงคาดการณ์ (Predictive Maintenance: PdM) ไปจนถึงช่วงการทำงานของเครื่องเครื่องตัดโลหะแผ่นด้วยพลังน้ำแรงดันสูง Water Jet ที่เหมาะสมเพื่อนำไปสู่การปรับปรุงกระบวนการตัดอย่างต่อเนื่อง การใช้เซ็นเซอร์และอัลกอริธึมร่วมกันเพื่อสร้างการแจ้งเตือนไปยังผู้ใช้งานนั้น จะช่วยเพิ่มความทนทานของเครื่องเครื่องตัดโลหะแผ่นด้วยพลังน้ำแรงดันสูง Water Jet และทำให้มั่นใจได้ว่าระบบจะยังคงดำเนินการได้อย่างเหมาะสมที่สุด โดยผลจากการใช้ระบบแบบเชื่อมต่อ (Connected system) จะช่วยทำให้กระบวนการซ่อมบำรุง, กระบวนการจัดการ และกระบวนการติดต่อสื่อสารกับบริษัท Flow ง่ายยิ่งขึ้น โดยไม่เพียงแต่ตรวจจับความเสี่ยงที่อาจเกิดขึ้นได้เท่านั้น แต่ยังให้แนวทางการทำงานที่ชัดเจนเพื่อลดปัญหาในกระบวนการผลิตและแก้ไขปัญหาในกระบวนการผลิตได้ตรงจุดอีกด้วย

Article by: Siam Anankit Ltd., Part. & MEGATech

Click Here >> www.siamanankit.com