Tungaloy-NTK Cutting Tool (Thailand) Co., Ltd. ร่วมงาน Asia Dealer Seminar 2025 ณ สำนักงานใหญ่ เมืองอิวากิ ประเทศญี่ปุ่น เมื่อวันที่ 14-18 กรกฎาคม 2568 ที่ผ่านมา โดยมีวัตถุประสงค์เพื่อให้มีการนำเสนอแนวทางการเติบโตของอุตสาหกรรมไทยให้แข็งแกร่งโดยผ่านตัวแทนจำหน่าย พร้อมกิจกรรมแลกเปลี่ยนประสบการณ์ภายใต้หัวข้อ “The Road to Success” ซึ่งเปิดโอกาสให้ดีลเลอร์ได้แบ่งปันมุมมองและแนวทางในการสร้างความสำเร็จร่วมกัน อีกทั้งยังมีการประกาศผลและมอบ Dealer Award 2025 เพื่อยกย่องผลงานยอดขายที่ยอดเยี่ยมตลอดปีที่ผ่านมา สะท้อนถึงความแข็งแกร่งของเครือข่ายพันธมิตรในประเทศไทยอย่างแท้จริง

งานเริ่มต้นอย่างอบอุ่นด้วยคำกล่าวเปิดงานโดยคุณซาโตชิ คิโนชิตะ President and Chief Executive Officer , Tungaloy Corporation ซึ่งได้แสดงความยินดีและมอบรางวัลแก่ตัวแทนจำหน่ายจากประเทศไทยที่มีผลงานยอดเยี่ยมประจำปี พร้อมกล่าวชื่นชมบทบาทของตัวแทนจำหน่ายไทยในฐานะกำลังสำคัญในการขับเคลื่อนธุรกิจของบริษัท ท่านยังได้เน้นย้ำถึงความสำคัญของ “พลังการขาย” ว่าเป็นหัวใจหลักในการผลักดันองค์กรให้เติบโต แม้ในช่วงเวลาที่เศรษฐกิจโลกมีความผันผวน ทั้งนี้ บริษัท Tungaloy ยังคงยึดมั่นในการให้การสนับสนุนพันธมิตรในภูมิภาคนี้อย่างต่อเนื่องและมั่นคง

จากนั้น คุณดีแลน คอร์ Managing Director, Tungaloy-NTK Cutting Tool (Thailand) Co., Ltd. ได้กล่าวแสดงความยินดีและขอบคุณตัวแทนจำหน่ายจากประเทศไทยทุกท่าน สำหรับความร่วมมืออันแน่นแฟ้นที่มีส่วนสำคัญในการขับเคลื่อนการเติบโตของธุรกิจในประเทศไทยอย่างต่อเนื่อง ทั้งนี้ ท่านได้กล่าวว่า “การเติบโตของเราไม่ได้เกิดขึ้นเพียงจากยอดขายเท่านั้น แต่เป็นผลลัพธ์จากการมุ่งมั่นพัฒนาผลิตภัณฑ์ที่มีคุณภาพและประสิทธิภาพสูง” พร้อมเน้นย้ำถึงความสำคัญของการแลกเปลี่ยนประสบการณ์ระหว่างดีลเลอร์ ซึ่งถือเป็นปัจจัยสำคัญในการสร้างความแข็งแกร่งและการเติบโตร่วมกันอย่างยั่งยืนในระยะยาว

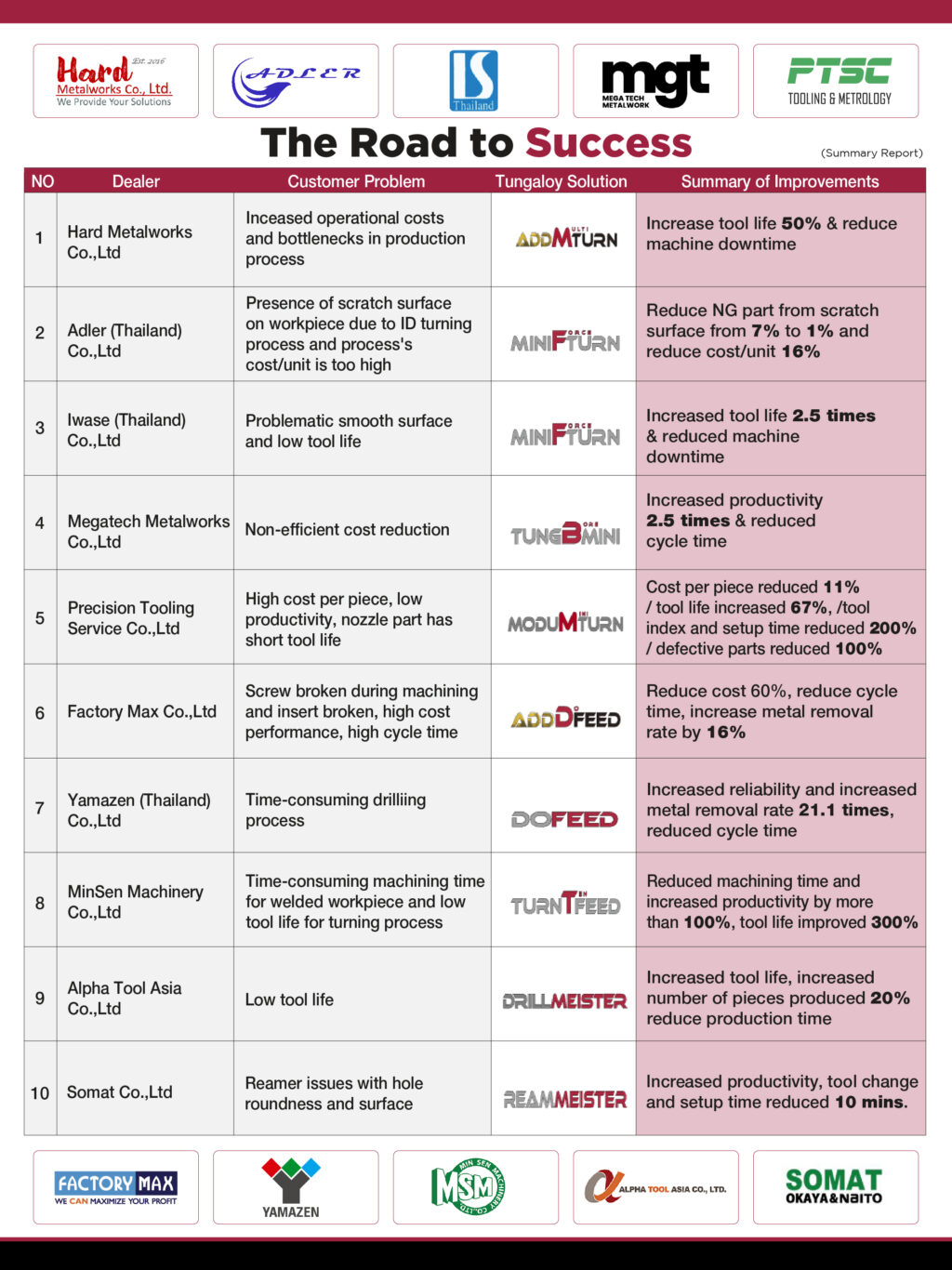

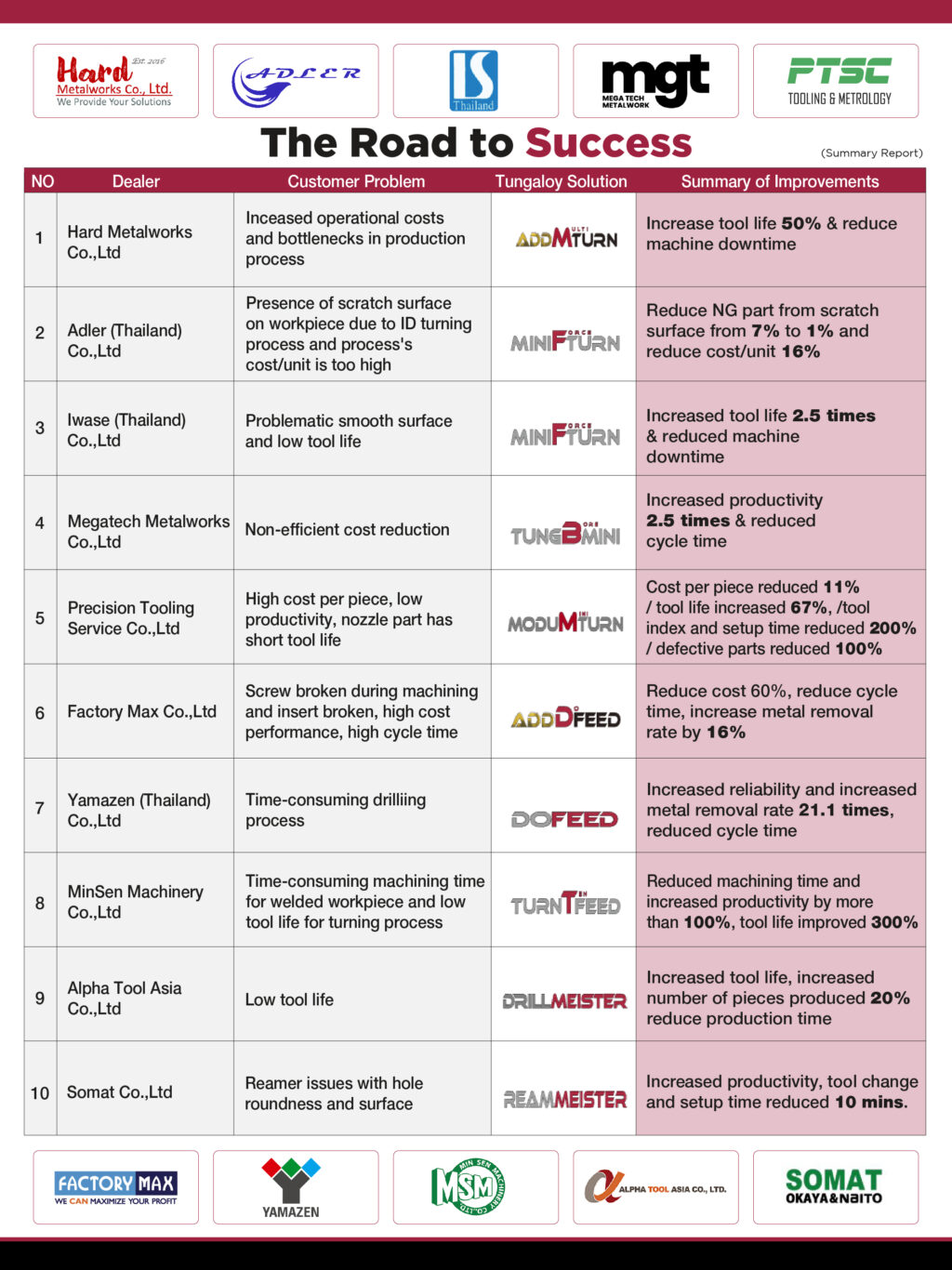

ลำดับต่อมา ดร.นิธิชัย จิตกุศลรุ่งเรือง Marketing Executive & Product Specialist ได้ทำหน้าที่เป็นผู้ดำเนินรายการในหัวข้อ “The Road to Success” ซึ่งเป็นช่วงเวลาสำคัญของงาน โดยมีดีลเลอร์จาก 10 บริษัท ร่วมขึ้นเวทีเพื่อแบ่งปันประสบการณ์ความสำเร็จ (Success Story) ในการนำผลิตภัณฑ์ของ Tungaloy ไปใช้แก้ไขปัญหาและพัฒนากระบวนการผลิตในรูปแบบที่หลากหลาย ทั้งนี้ ผู้เข้าร่วมต่างได้รับประโยชน์จากแนวทางการปรับปรุง (Improvement) ที่พิสูจน์แล้วว่าได้ผลจริงในแต่ละประเภทธุรกิจ นับเป็นการแลกเปลี่ยนความรู้ที่สร้างแรงบันดาลใจและเปิดมุมมองใหม่ให้แก่ผู้ร่วมงานทุกท่าน

MEGA Tech ขอนำเสนอ “The Road to Success” ผลงานระดับมาสเตอร์พีซจากทีม ดีลเลอร์ แนวหน้าของประเทศไทย ถ่ายทอดแนวคิดและประสบการณ์สู่ความสำเร็จ เพื่อยกระดับประสิทธิภาพการผลิตของโรงงานอย่างแท้จริง

The Road to Success (Summary Report)

จากนั้นเข้าสู่พิธีมอบรางวัล Dealer Award 2025 เพื่อยกย่องดีลเลอร์ที่มีผลงานยอดเยี่ยมประจำปี โดยแบ่งออกเป็น 2 หมวดรางวัลสำคัญ สะท้อนถึงความมุ่งมั่น ทุ่มเท และศักยภาพอันยอดเยี่ยมในการขับเคลื่อนความสำเร็จร่วมกับ Tungaloy ได้อย่างเต็มภาคภูมิ

♦️ รางวัลยอดขายสินค้าใหม่ดีเด่น ADDFORCE

- 🥇อันดับ 1: Precision Tools Service (Thailand) Co., Ltd. (PTS)

- 🥈อันดับ 2: TT Fuji Tool Support Co., Ltd.

- 🥉อันดับ 3: Yamazen (Thailand) Co., Ltd.

♦️ รางวัลยอดขายผลิตภัณฑ์ดีเด่น TUNGALOY

- 🥇อันดับ 1: Precision Tools Service (Thailand) Co., Ltd. (PTS)

- 🥈อันดับ 2: Adler (Thailand) Co., Ltd.

- 🥉อันดับ 3: Factory Max Co., Ltd.

MEGA Tech ขอพาทุกท่านไปรับฟังเสียงจากผู้ได้รับรางวัล Dealer Award 2025 กับมุมมองที่มีต่อประโยชน์จากงานสัมมนา ผลิตภัณฑ์ใหม่ที่น่าสนใจเพื่อต่อยอดการขาย และความรู้สึกภาคภูมิใจที่ได้รับรางวัลอันทรงคุณค่าในปีนี้ ร่วมติดตามแรงบันดาลใจจากคนเก่งของเราได้เลย!

Precision Tools Service ( Thailand ) Co., Ltd.

คุณปรัชญา สิงหโภชน์ กล่าวว่า “การเข้าร่วมงานครั้งนี้ช่วยเสริมความมั่นใจในคุณภาพของผลิตภัณฑ์ Tungaloy จากกระบวนการผลิตที่ทันสมัย มีระบบอัตโนมัติและหุ่นยนต์ควบคุมคุณภาพอย่างแม่นยำ พร้อมเนื้อหาสัมมนาที่เจาะลึกเกี่ยวกับสินค้าใหม่และการใช้งานจริง ทำให้สามารถนำเสนอแก่ลูกค้าได้อย่างมั่นใจ ตลอดจนการดูแลจากทีมงานที่ใส่ใจในทุกรายละเอียด สะท้อนถึงวัฒนธรรมการบริการแบบญี่ปุ่นอย่างแท้จริง เป็นประสบการณ์ที่น่าประทับใจและควรมีอีกในอนาคต

การชมสายการผลิตจริงช่วยเสริมความมั่นใจในคุณภาพของโรงงาน ที่มีการควบคุมต้นทุนและคุณภาพได้ดีในทุกขั้นตอน โดยใช้เทคโนโลยี Industry 4.0 เช่น หุ่นยนต์และระบบตรวจสอบอัตโนมัติ และการโค้ตติ้งเม็ดอินเสิร์ต อีกจุดเด่นคือเทคโนโลยี 3D Printing ด้วยโลหะ ซึ่งรองรับการผลิตชิ้นงานซับซ้อนในระดับ Mass Production ได้อย่างมีประสิทธิภาพ.

สินค้าใหม่ที่น่าสนใจคือ Eco Insert: อินเสิร์ตขนาดเล็ก ราคาประหยัด ตอบโจทย์ลูกค้ากลุ่มที่เน้นการแข่งขันด้านต้นทุน และ TungJet: มีระบบไล่เศษชิพอัตโนมัติ เพิ่มประสิทธิภาพในการตัดเฉือน ลดปัญหาในกระบวนการผลิต ซึ่งผลิตภัณฑ์เหล่านี้ช่วยขยายตลาดใหม่และแก้ปัญหาให้ลูกค้าได้ตรงจุด

รางวัลที่ได้รับสะท้อนถึงความร่วมมือและความมุ่งมั่นของทีมงานในการนำเสนอสินค้าคุณภาพ ที่ตอบโจทย์ลูกค้าอย่างแท้จริง โดย Tungaloy มีโซลูชันครบวงจรและแอปพลิเคชันหลากหลาย ช่วยผลักดันยอดขายอย่างต่อเนื่อง

ปีหน้า บริษัทฯ จะนำความรู้จากสัมมนาไปประยุกต์ใช้ในการให้คำปรึกษาลูกค้า มุ่งเน้นการเพิ่มประสิทธิภาพและลดต้นทุนการผลิต พร้อมขยายตลาดสู่กลุ่มลูกค้าใหม่ ความมั่นใจที่ได้จากการเยี่ยมชมโรงงานทำให้เชื่อมั่นว่าสินค้าของ Tungaloy มีคุณภาพสูง เชื่อถือได้ และสามารถแข่งขันได้ในตลาดอย่างยั่งยืน” คุณปรัชญา สิงหโภชน์ เน้นย้ำด้วยความเชื่อมั่น

Adler ( Thailand ) Co., Ltd.

คุณประทวน ดิถีพรรณ กล่าวว่า “งานสัมมนาครั้งนี้มอบความรู้เชิงลึกที่มีคุณค่า โดยเฉพาะการนำเสนอนวัตกรรมใหม่ของแต่ละกลุ่มผลิตภัณฑ์จาก Tungaloy Japan ซึ่งโดดเด่นด้านประสิทธิภาพ ความแม่นยำ และการผลิตที่มีคุณภาพสูง ช่วยให้ตัวแทนจำหน่ายสามารถนำเสนอผลิตภัณฑ์ได้อย่างตรงจุด ตอบโจทย์ความต้องการของลูกค้าในภาคอุตสาหกรรมได้อย่างแท้จริง

การเยี่ยมชมโรงงานและชมการสาธิตเปรียบเทียบกับผลิตภัณฑ์คู่แข่ง สะท้อนให้เห็นถึงความมุ่งมั่นในการวิจัยและพัฒนาของ Tungaloy ในทุกกลุ่มผลิตภัณฑ์ ทั้ง Drill, End Mill, Turning, Groove และ Insert ซึ่งช่วยเพิ่มความมั่นใจในการนำเสนอสินค้าให้กับลูกค้าได้อย่างมีประสิทธิภาพ ตรงตามการใช้งาน และสร้างความเชื่อมั่นในคุณภาพระดับสากล

Ceramic End Mill เป็นผลิตภัณฑ์ใหม่ที่มีศักยภาพสูง รองรับงานความเร็วสูง (High-Speed Machining) ด้วยความเร็วในการตัดที่มากกว่า Carbide ถึง 15–30 เท่า ช่วยลดเวลาในการผลิต พร้อมให้ผิวงานที่มีคุณภาพ เหมาะสำหรับอุตสาหกรรมที่ต้องการความแม่นยำสูง และมีแนวโน้มจะเป็นผลิตภัณฑ์สำคัญในอนาคต

รางวัลยอดขายอันดับ 2 ถือเป็นความสำเร็จและความภาคภูมิใจของบริษัท จากความร่วมมืออย่างใกล้ชิดกับ Tungaloy (Thailand) ในการนำเสนอผลิตภัณฑ์ที่ตรงกับการใช้งานและแก้ไขปัญหาให้ลูกค้าได้อย่างมีประสิทธิภาพ

ปีหน้า บริษัทฯ จะมุ่งเน้นการให้บริการและคำปรึกษาเชิงลึก แนะนำผลิตภัณฑ์ใหม่ที่ช่วยเพิ่มผลผลิตและลดต้นทุน เพื่อสร้างความพึงพอใจให้ลูกค้าอย่างต่อเนื่อง พร้อมรักษาความสัมพันธ์กับลูกค้าคุณภาพและผลักดันยอดขายให้เติบโตอย่างมั่นคง” คุณประทวน ดิถีพรรณ กล่าวสรุปอย่างมั่นใจ

TT Fuji Tool Support Co., Ltd.

คุณปัญญา สำเร็จรัมย์ กล่าวว่า “ สิ่งที่ได้รับประโยชน์สูงสุดคือ New Products เพราะช่วยให้เข้าใจแนวคิดเบื้องหลังการพัฒนาผลิตภัณฑ์ใหม่ของ Tungaloy ที่มุ่งเน้นการแก้ปัญหาการใช้งานจริงของลูกค้า ลดต้นทุน และเพิ่มประสิทธิภาพการผลิต โดยผสานเทคโนโลยี IoT และนวัตกรรมสมัยใหม่ จนได้ผลิตภัณฑ์ใหม่ที่ครบวงจรและเชื่อถือได้

การเยี่ยมชมโรงงานครั้งนี้สร้างความมั่นใจในกระบวนการผลิตที่ทันสมัย โดยเฉพาะการใช้เทคโนโลยี 3D Printing สำหรับผลิตเครื่องมือตัดที่มีความซับซ้อนสูง ร่วมกับระบบควบคุมคุณภาพในทุกขั้นตอน จึงมั่นใจได้ว่าสินค้ามีคุณภาพสูง ตรงตามความต้องการ และพร้อมสร้างความเชื่อมั่นเมื่อนำเสนอแก่ลูกค้า.

TUNGMEISTER Endmill เป็นผลิตภัณฑ์ใหม่ที่มีศักยภาพสูงในการเพิ่มยอดขาย ด้วยการรวมกระบวนการ Roughing และ Finishing ไว้ในเครื่องมือเดียว ช่วยลดเวลาและเพิ่ม Productivity ได้อย่างมีประสิทธิภาพ อีกทั้งยังลดต้นทุนด้านเวลา สต๊อก และต้นทุนต่อชิ้นงาน เหมาะสำหรับกลุ่มอุตสาหกรรมที่เน้นประสิทธิภาพและความคุ้มค่าในการผลิต.

ในนามบริษัทรู้สึกยินดีและความภาคภูมิใจเป็นอย่างยิ่งที่ได้รับรางวัลอันทรงคุณค่าในครั้งนี้ ความสำเร็จครั้งนี้เกิดขึ้นได้จากความร่วมแรงร่วมใจของทีมงานฝ่ายเทคนิคและฝ่ายขายทุกท่าน ที่ทุ่มเททำงานอย่างหนักร่วมกับลูกค้า เพื่อช่วยให้บรรลุเป้าหมายในการ ลดต้นทุนการผลิตอย่างมีประสิทธิภาพ รางวัลนี้ถือเป็นบทพิสูจน์ว่า ผลิตภัณฑ์จาก Tungaloy สามารถตอบโจทย์ความต้องการของลูกค้าได้อย่างตรงจุด และสร้างความพึงพอใจในทุกมิติ ทั้งนี้ บริษัทฯ มั่นใจว่าในปีหน้า ยอดขายจะเติบโตยิ่งขึ้นจากกลุ่ม ผลิตภัณฑ์ใหม่ ที่มุ่งเน้นการ ลดเวลาการผลิต และเพิ่มประสิทธิภาพการทำงาน (Productivity) ให้กับลูกค้าได้อย่างแท้จริง” คุณปัญญา สำเร็จรัมย์ กล่าวสรุปได้อย่างน่าประทับใจ

Factory Max Co., Ltd.

คุณศักดิ์ชาย เสือประเสริฐ กล่าวว่า “ภายในงานนี้ มีจุดเด่นที่น่าสนใจคือการผสานทั้งภาคทฤษฎีและการสาธิตใช้งานจริง สามารถเห็นภาพการทำงานของผลิตภัณฑ์ได้ชัดเจนมากขึ้น ซึ่งในระหว่างการเข้าร่วมกิจกรรม ก็เกิดแรงบันดาลใจทันทีว่าสินค้าตัวใดสามารถตอบโจทย์ลูกค้ารายใดได้บ้าง

หนึ่งในผลิตภัณฑ์ใหม่ที่น่าสนใจเป็นพิเศษคือ AddMultiTurn เม็ดมีดกลึงที่สามารถใช้งานได้ทั้งด้านหน้าและด้านหลัง ช่วยลดเวลาเครื่องจักรลงได้ถึง 50% และเพิ่มประสิทธิภาพการผลิต เหมาะอย่างยิ่งสำหรับกลุ่มลูกค้าในสายการผลิตแบบ mass production ที่มีความต้องการสูงในลักษณะงานเช่นนี้ ผลิตภัณฑ์นี้มีศักยภาพสูงในการต่อยอดทางธุรกิจ โดยแม้จะต้องมีการทดสอบ (test cut) เพื่อยืนยันผลลัพธ์ก่อนเสนอขาย แต่คุณสมบัติและฟังก์ชันของเครื่องมือนี้ถือว่าโดดเด่นและมีโอกาสสูงในการเปลี่ยนเป็นคำสั่งซื้อจริง

รู้สึกเป็นเกียรติอย่างยิ่งที่ Tungaloy มอบโอกาสให้ Factory Max ได้มีส่วนร่วมในครั้งนี้ เชื่อว่าสาเหตุที่เราได้รับรางวัลมาจากแนวทางการทำงานที่สอดคล้องกัน โดยมุ่งเน้นการนำเสนอ “โซลูชัน” ที่ตอบโจทย์ลูกค้าอย่างแท้จริง ทั้งในด้านการแก้ไขปัญหาและการพัฒนากระบวนการผลิต แผนการเพื่อมุ่งสู่การคว้าอันดับหนึ่งได้เริ่มต้นขึ้นแล้ว โดยมีการดำเนินการตามขั้นตอนที่วางไว้ แม้บางส่วนยังไม่สามารถเปิดเผยได้ในขณะนี้ แต่ทุกอย่างกำลังเดินหน้าอย่างมั่นคงและเป็นระบบ ด้วยเป้าหมายชัดเจนและความมุ่งมั่นเต็มที่ การเตรียมความพร้อมจึงเริ่มขึ้นทันที โดยตั้งใจสร้างผลงานที่ดีที่สุดในรอบการแข่งขันครั้งถัดไป ความสำเร็จจะเกิดขึ้นได้ด้วยความร่วมมือและแรงสนับสนุนจากทีมงาน Tungaloy ซึ่งเป็นกำลังสำคัญในการก้าวสู่เป้าหมายที่ตั้งไว้” คุณศักดิ์ชาย เสือประเสริฐ กล่าวปิดท้ายด้วยความมุ่งมั่น

Yamazen (Thailand) Co., Ltd.

คุณอรุณวัชรี ซิ้มเจริญ กล่าวว่า “ การเข้าร่วมสัมมนาครั้งนี้ให้ประโยชน์อย่างมาก ด้วยเนื้อหาที่เข้มข้นและครอบคลุมทั้งด้านเทคนิคและคุณสมบัติเฉพาะของแต่ละผลิตภัณฑ์ ช่วยให้เข้าใจจุดเด่นของ Tungaloy ชัดเจนยิ่งขึ้น ส่งเสริมความสามารถในการให้คำแนะนำแก่ลูกค้าได้อย่างตรงจุดและน่าเชื่อถือมากขึ้น

จากการเยี่ยมชมกระบวนการผลิตภายในโรงงาน (Plant Tour) รู้สึกประทับใจในระบบการผลิตที่ทันสมัย โดยใช้เครื่องจักรอัตโนมัติและเทคโนโลยีขั้นสูง โดยเฉพาะในขั้นตอนการผลิตเม็ดมีดและการขึ้นรูป insert ซึ่งมีความแม่นยำสูง สะท้อนถึงศักยภาพของ Tungaloy ในการผลิตสินค้าที่มีคุณภาพระดับสากล จุดแข็งนี้สามารถนำไปใช้เป็นจุดขายหลักเมื่อนำเสนอแก่ลูกค้าในกลุ่มอุตสาหกรรมที่ต้องการความแม่นยำสูง เช่น ชิ้นส่วนยานยนต์และอุตสาหกรรมอากาศยาน

ผลิตภัณฑ์ที่มีแนวโน้มสร้างยอดขายได้อย่างโดดเด่น คือ ADDFORCE DOFEED ซึ่งออกแบบมาสำหรับงานกัดความเร็วสูง (High Feed Milling) ที่กำลังเป็นที่ต้องการในตลาด โดยเฉพาะในกลุ่มอุตสาหกรรมยานยนต์และแม่พิมพ์ ด้วยจุดเด่นด้านอายุการใช้งานที่ยาวนานและประสิทธิภาพในการลดเวลาเครื่องจักร จึงสามารถนำเสนอแก่ลูกค้าได้อย่างมั่นใจ และเพิ่มโอกาสในการปิดการขายได้อย่างมีประสิทธิภาพ

รู้สึกยินดีและเป็นเกียรติอย่างยิ่งที่ได้รับรางวัลยอดขายอันดับ 3 สำหรับผลิตภัณฑ์ ADDFORCE ซึ่งสะท้อนถึงความมุ่งมั่นของทีมงาน ความไว้วางใจจากลูกค้า และการสนับสนุนจากทีม Tungaloy

ความสำเร็จครั้งนี้เกิดจากความเชื่อมั่นในคุณภาพของ ADDFORCE ที่ตอบโจทย์ลูกค้าได้ทั้งด้านประสิทธิภาพ ความแม่นยำ และความคุ้มค่า ปีหน้า บริษัทฯจะเน้นให้ข้อมูลเชิงลึกแก่ลูกค้า ผ่านการสาธิตและให้คำปรึกษา พร้อมขยายฐานลูกค้าใหม่ เพื่อผลักดันยอดขายให้เติบโตอย่างต่อเนื่องและยั่งยืน” คุณอรุณวัชรี ซิ้มเจริญ สรุปด้วยรอยยิ้มที่จริงใจ

MEGATech ขอจบการรายงาน Dealer Seminar เพียงเท่านี้ และเตรียมพบกับนวัตกรรมล้ำสมัยจาก Tungaloy ที่จะพลิกโฉมอุตสาหกรรมยุค Industry 4.0 ภายใต้แนวคิด HIGH Feeds & Speed ที่ทั้งเร็ว แรง และแม่นยำ เร่งสปีดการผลิต เพิ่มประสิทธิภาพแบบเหนือชั้น กับเทคโนโลยีล่าสุดที่คุณไม่ควรพลาด! ติดตามความเข้มข้นในตอนต่อไป—แรงกว่านี้ ไม่มีอีกแล้ว!🚀

ติดตามบทความ Episode 2 Tungaloy Asia Seminar 2025 (Factory Tour) ได้ที่ลิงค์นี้ << Click Here

Article by: MEGA Tech << Click Here