ในช่วงที่เศรษฐกิจเผชิญความไม่แน่นอนจากปัจจัยต่าง ๆ สิ่งที่ธุรกิจควรทำคือปรับปรุงประสิทธิภาพเพื่อเพิ่มผลประกอบการ สำหรับผู้ผลิตชิ้นส่วนโลหะ หมายถึงการลดรอบเวลาการผลิตต่อชิ้นให้สั้นลง ด้วยแนวคิดนี้ Thaimach และ Hurco รวมถึงพันธมิตรอย่าง PTSC และ Autodesk จึงได้จัดงานโอเพ่นเฮาส์เพื่อแสดงและสาธิตเครื่องจักรและโซลูชันงานตัดเฉือนโลหะใหม่ให้แก่ลูกค้าและผู้เยี่ยมชม

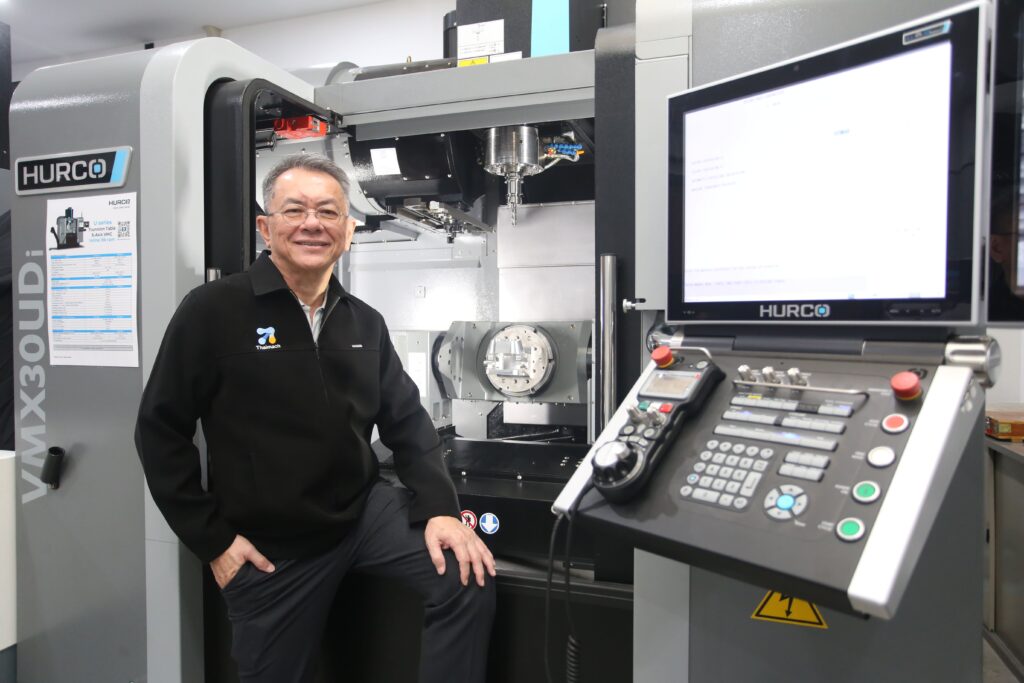

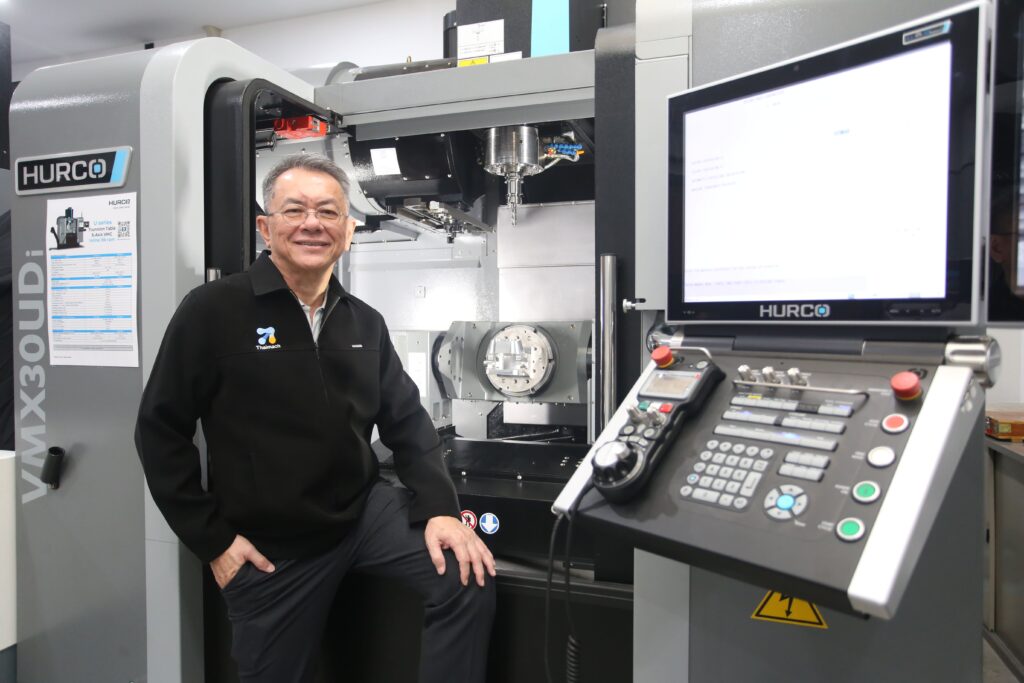

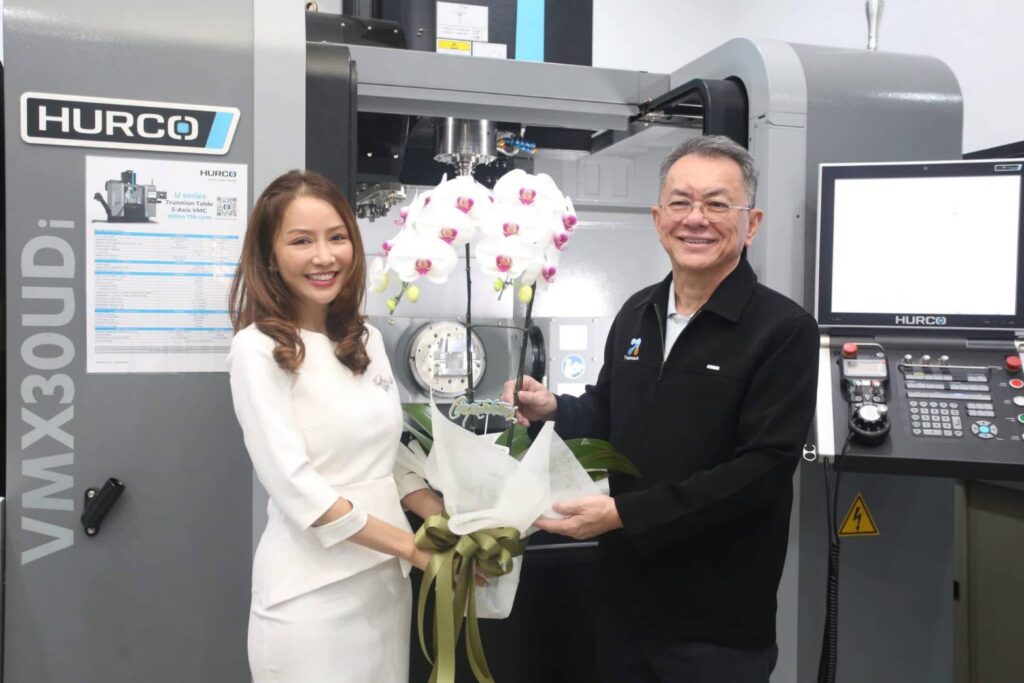

งานเริ่มต้นด้วยคำกล่าวต้อนรับและแนะนำงานเบื้องต้นโดยคุณทวีศักดิ์ ศรีสันติสุข กรรมการผู้จัดการกรรมการ บริษัท ไทยแมค เซลส์แอนด์เซอร์วิส จำกัด MEGATech มีความยินดีที่จะนำเสนองานนี้โดยมีไฮไลท์ดังต่อไปนี้

ความท้าทายของงานตัดเฉือนโลหะและการเขียนโปรแกรม

คุณไว ยิป ลี ผู้จัดการทั่วไปของ Hurco (S.E. Asia) Pte. Ltd. ได้ทบทวนความท้าทายในการทำให้รอบเวลาการผลิตสั้นลง ซึ่งเกิดจากสองปัจจัย ได้แก่ การเขียนโปรแกรมและความสามารถในการตัดเฉือน ปัญหาด้านการเขียนโปรแกรมส่วนใหญ่เกิดจากการขาดช่างเขียนโปรแกรมและช่างเครื่องที่มีทักษะ จึงแนะนำให้ผู้ผลิตใช้การเขียนโปรแกรมในหน้างานเพื่อแบ่งเบาภาระของโปรแกรมเมอร์ CAM ซึ่งจะช่วยลดระยะเวลาการเรียนรู้และทำให้ทำงานเสร็จเร็วขึ้น นอกจากนี้ ผู้ผลิตยังต้องปรับตัวรับรูปแบบการผลิตที่มีความยืดหยุ่น ทั้งการผลิตล็อตใหญ่ ล็อตเล็ก และแม้แต่การผลิตชิ้นเดียว ซึ่งแน่นอนว่าต้องสิ้นเปลืองเวลาในการเขียนโปรแกรมและตั้งค่ามากขึ้น

ลงทุนในเครื่องจักรที่เหมาะสม

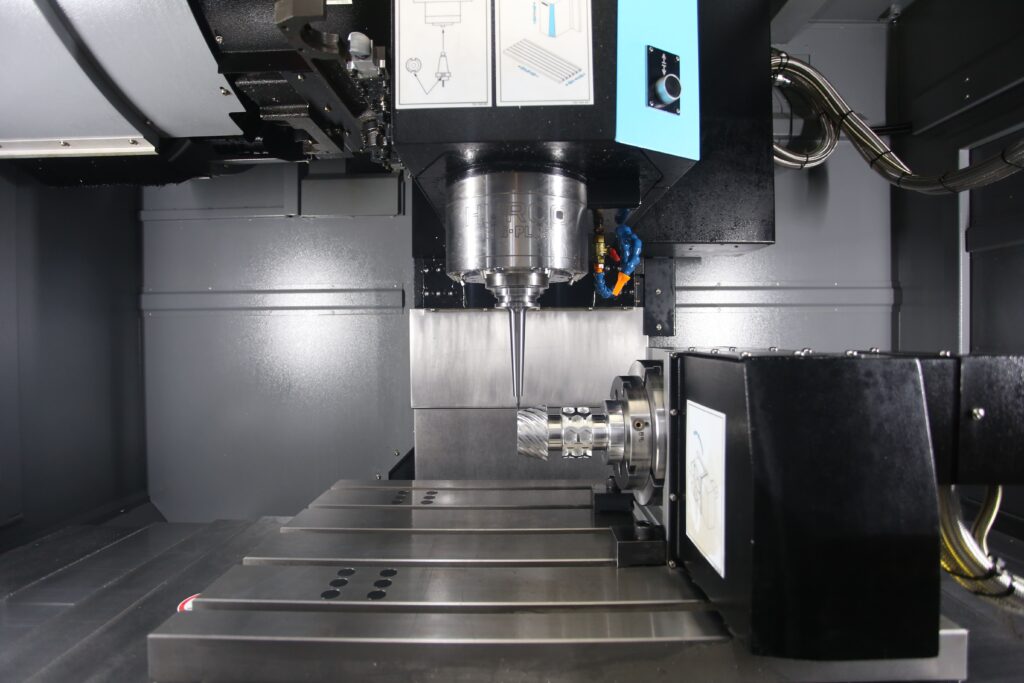

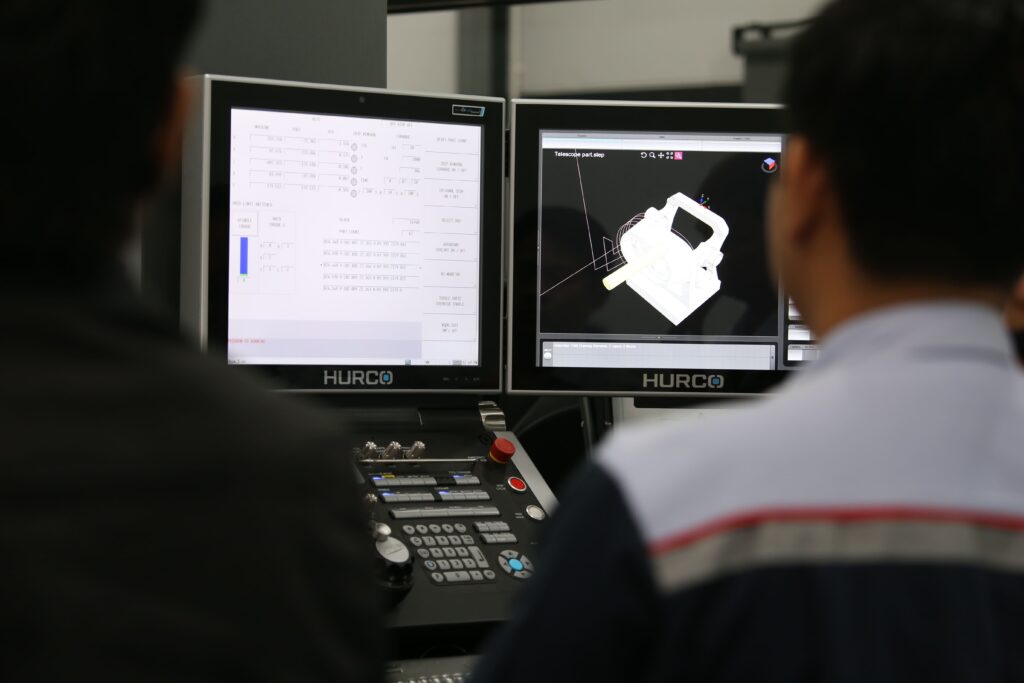

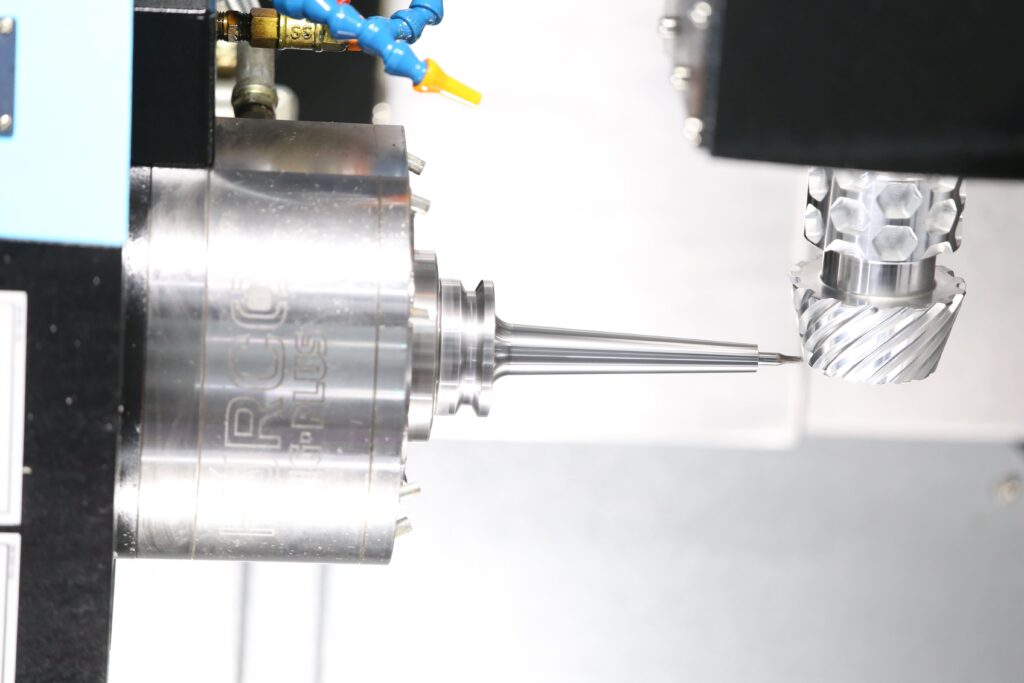

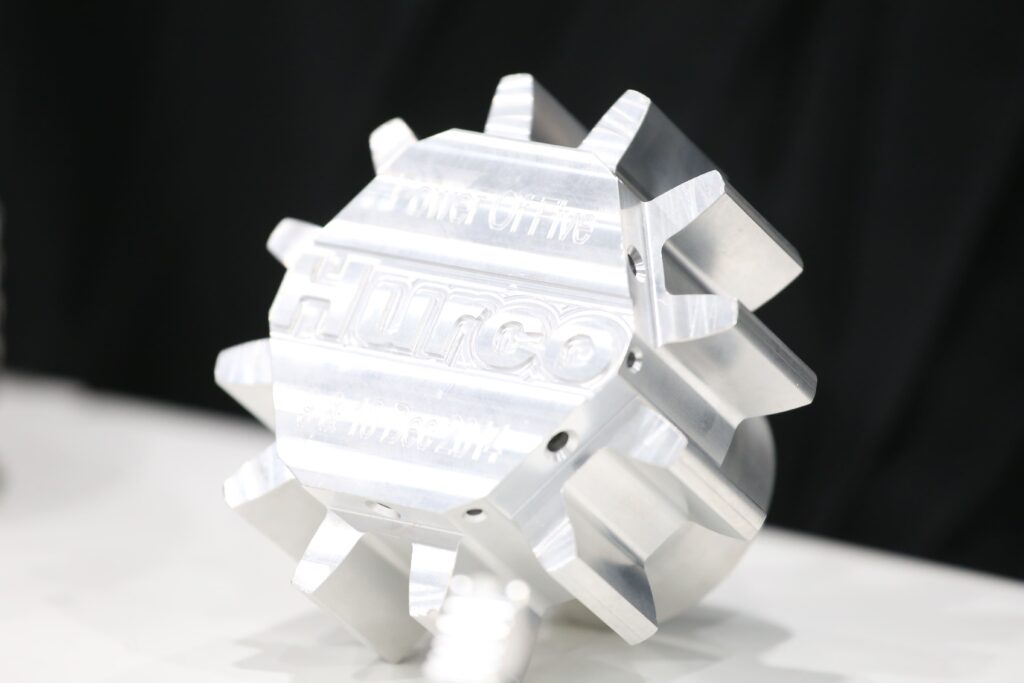

งานโอเพ่นเฮาส์ครั้งนี้ได้แนะนำและสาธิตเครื่องกัด CNC แนวตั้งประสิทธิภาพสูง รุ่น VMX24Di และ VMX30UDi จาก Hurco เครื่องจักรขนาดกะทัดรัดสองรุ่นนี้มีความเร็วรอบสปินเดิลสูงสุด 15,000 รอบต่อนาที ให้กำลัง 20 แรงม้าหรือ 15 กิโลวัตต์ มาพร้อมกับเทคโนโลยีควบคุม CNC รุ่น Max5 ของ Hurco ส่วนฮาร์ดแวร์ประกอบด้วยหน่วยความจำ RAM 4GB โปรเซสเซอร์ดูอัลคอร์ 2.7 GHz และฮาร์ดไดรฟ์โซลิดสเตต 128 GB นับเป็นชุดควบคุมที่ยืดหยุ่นที่สุดในอุตสาหกรรม ซึ่งลูกค้าตัดสินใจได้ว่าจะใช้วิธีการเขียนโปรแกรมแบบใดดีที่สุดสำหรับแต่ละงาน ทั้งโปรแกรมโต้ตอบหน้าเครื่อง, NC หรือ แบบผสม NC/โต้ตอบหน้าเครื่อง ยังเพิ่มการปรับปรุงคุณสมบัติมากกว่า 80 รายการ การทดสอบการใช้งานจริงโดยลูกค้า การออกแบบตามหลักสรีรศาสตร์ และความยืดหยุ่นในการเขียนโปรแกรม จึงพิสูจน์แล้วว่า MAX5 เป็นที่ชื่นชอบของลูกค้ามากที่สุดในตลาด

ซีรีส์ VMX มาพร้อมเทคโนโลยี UltiMotion ที่ได้รับการจดสิทธิบัตร ซึ่งช่วยให้ประมวลผลได้เร็วถึง 4,000 bps และความสามารถในการควบคุมล่วงหน้าถึง 10,000 บล็อก ด้วยซอฟต์แวร์อัลกอริธึมขั้นสูงที่ช่วยลดภาระของบอร์ดควบคุมการเคลื่อนที่ ซีรีส์ VMX จึงลดเวลาการทำงานลงได้ 30% ยิ่งไปกว่านั้น ด้วย UltiMotion คุณภาพการตัดจะไม่ขึ้นอยู่กับฮาร์ดแวร์เหมือนกับระบบควบคุมการเคลื่อนที่ทั่วไป จึงมีการสั่นสะเทือนและเครื่องจักรกระตุกน้อยลง ทำให้ได้พื้นผิวงานที่เรียบเนียนขึ้น

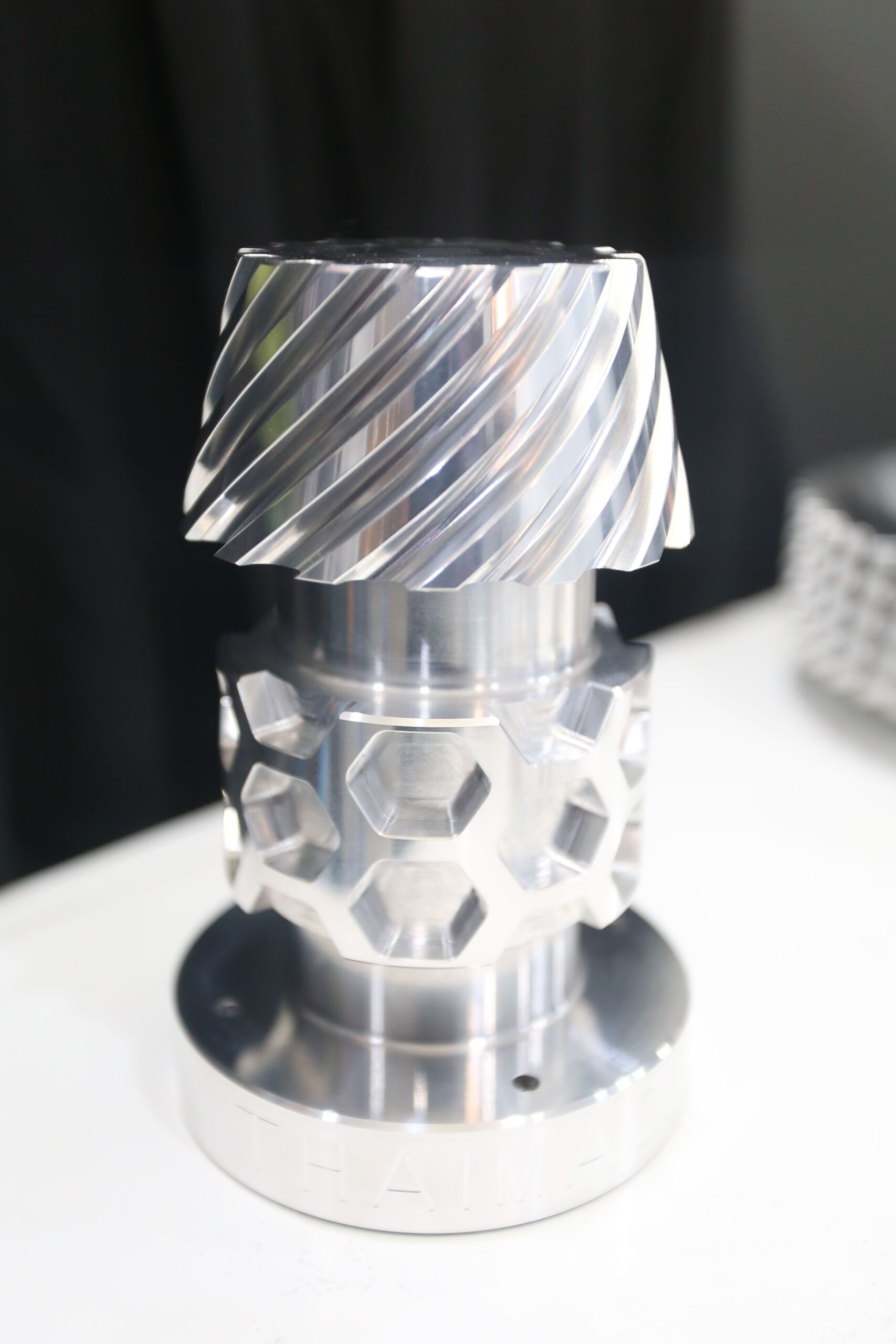

การตัด 5 แกนสำหรับชิ้นส่วนที่เน้นความแม่นยำและซับซ้อนขึ้น

ในงานยังได้แนะนำ VMX30UDi แมชชีนนิงเซนเตอร์ 5 แกนที่มีโต๊ะรองชิ้นงานในตัว การกัด 5 แกนช่วยลดเวลาในการผลิต ซึ่งส่วนใหญ่มาจากเวลาในการตั้งค่าเครื่องที่ลดลง ส่งผลโดยตรงให้เวลาต่อรอบการทำงานสั้นลงและชิ้นส่วนมีความแม่นยำมากขึ้น การกัด 5 แกนยังช่วยให้สามารถใช้เครื่องมือที่สั้นลง ซึ่งช่วยลดการสั่นสะเทือน ปรับปรุงคุณภาพพื้นผิวชิ้นงานและมีความแข็งแรงมากขึ้น การออกแบบที่มีโต๊ะรองชิ้นงานในตัวช่วยเพิ่มระยะห่างในแกน Z มากขึ้น ทำให้ VMX30UDi สามารถตัดเฉือนชิ้นส่วนที่มีน้ำหนักมากขึ้น ด้วยความสามารถตัดเฉือน 5 แกน ผู้ประกอบการจึงสามารถออกใบเสนอราคาชิ้นส่วนที่ซับซ้อนมากขึ้นได้

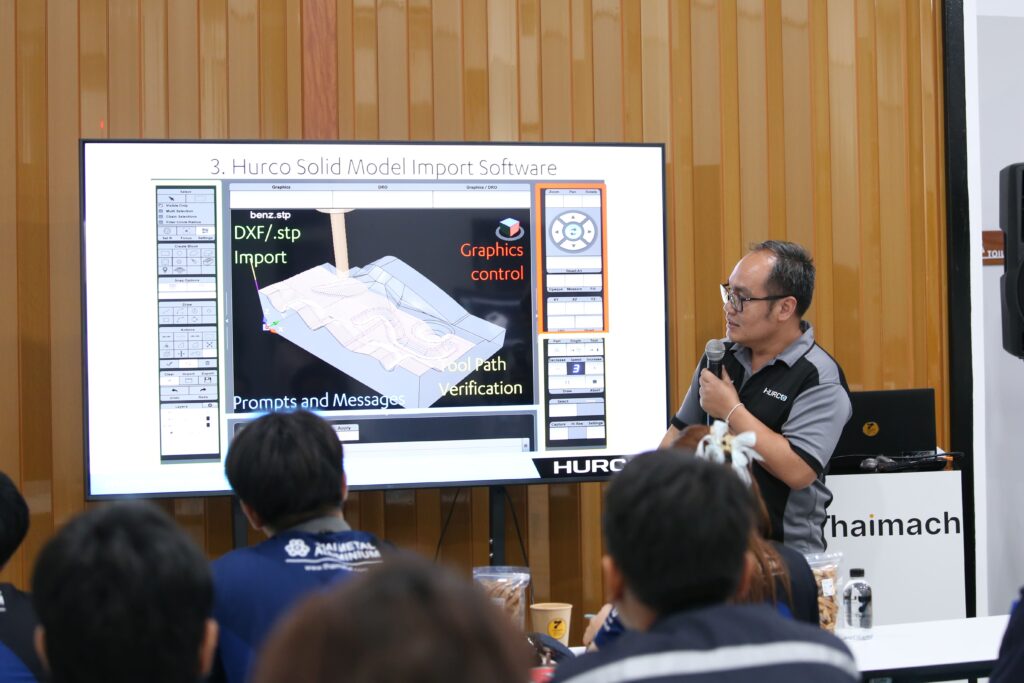

Solid Model Import เพื่อการเขียนโปรแกรมอย่างรวดเร็ว

ฟีเจอร์การควบคุมล่าสุดนี้ออกแบบมาเพื่อลดความซับซ้อนในการเขียนโปรแกรม ประหยัดเวลาและรักษาความแม่นยำด้วยการ click and cut อย่างง่ายดาย ด้วย Solid Model Import ผู้ใช้สามารถนำโมเดลโซลิด 3 มิติของลูกค้าไปนำเข้าในตัวควบคุม Max5 ได้โดยตรง สำหรับการเขียนโปรแกรมตัดเฉือน 5 แกน Solid Model Import จะแปลงระนาบโดยอัตโนมัติสำหรับการเขียนโปรแกรมแบบโต้ตอบ 5 แกนที่ง่ายดายโดยไม่ต้องป้อนข้อมูล

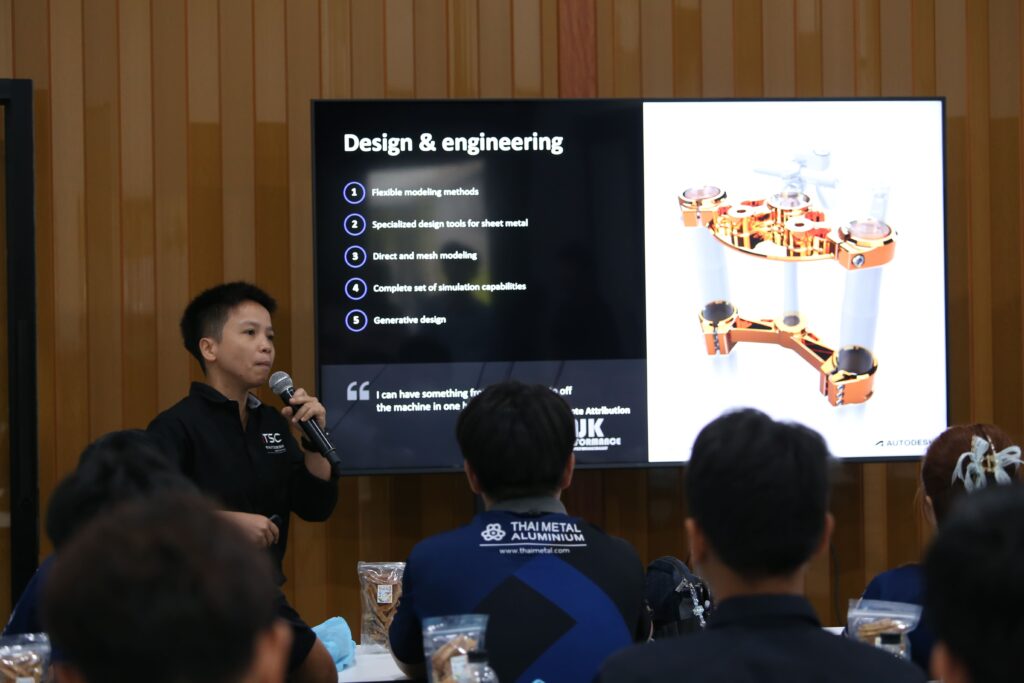

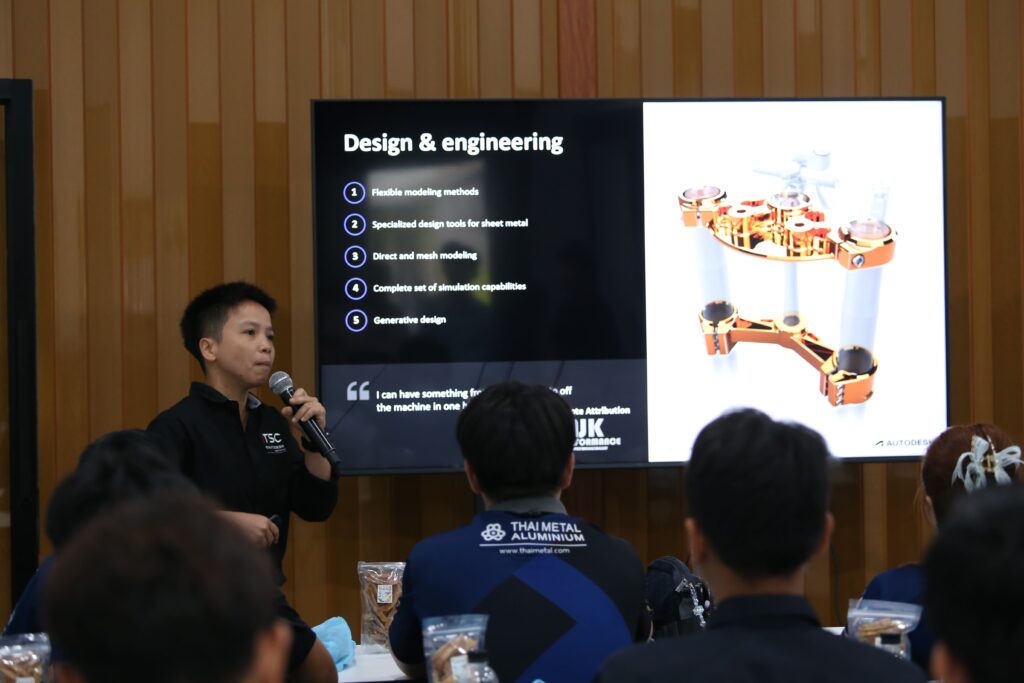

Autodesk ยกระดับกระบวนการแปรรูปแผ่นโลหะด้วย Fusion 360

อีกหนึ่งไฮไลท์สำคัญคือการนำเสนอจาก Autodesk บริษัทซอฟต์แวร์จากฝรั่งเศส ซึ่งนำเสนอชุดซอฟต์แวร์สำหรับการออกแบบงาน 3 มิติและการผลิตที่ครอบคลุมและเน้นความสามารถในการปรับปรุงกระบวนการจาก CAD เป็น CAM และเชื่อมต่อโดยตรงกับเครื่องจักร ทำให้ระยะเวลาในการผลิตชิ้นส่วนรวดเร็วขึ้น ในงานนี้ Autodesk ได้แนะนำซอฟต์แวร์ Fusion 360 ซึ่งออกแบบมาเพื่อรองรับกระบวนการผลิตที่หลากหลายสำหรับการแปรรูปแผ่นโลหะแผ่น รวมถึงการตัด การเจาะ การดัด และการเชื่อมด้วยเลเซอร์

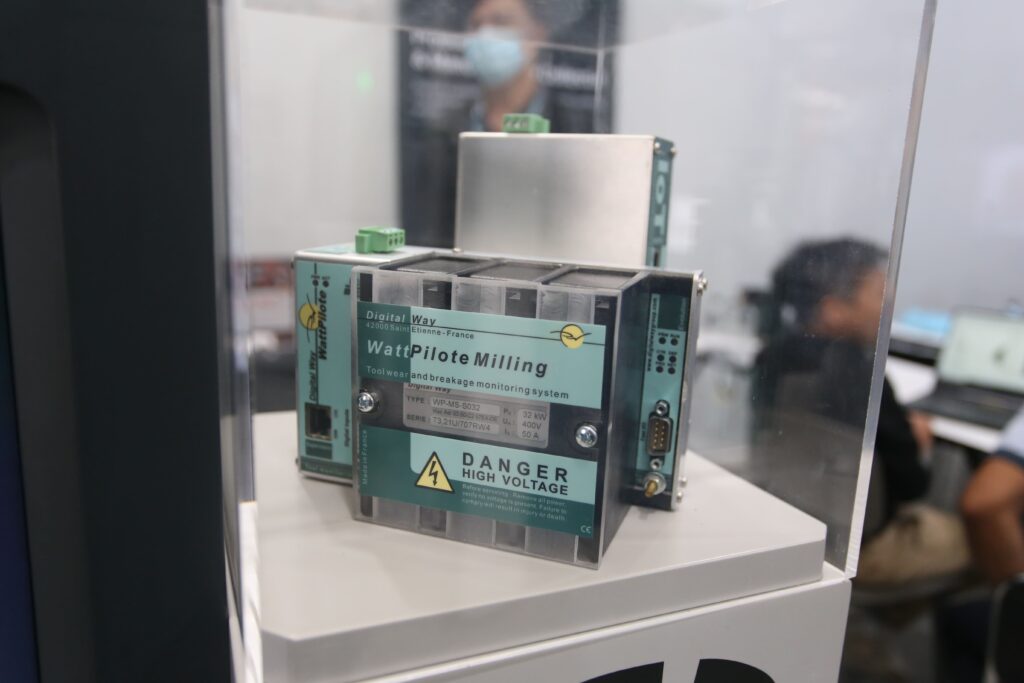

PTSC นำเสนอการประหยัดต้นทุนเครื่องมือด้วย WattPilote

WattPilote จาก Digital Way ระบบตรวจจับการสึกหรอและแตกหักของเครื่องมือ ผสมผสานเทคโนโลยีเฉพาะเพื่อมอบระบบตรวจสอบเครื่องมือที่มีประสิทธิภาพสูงสุดในโลก เป็นระบบตรวจสอบเครื่องมือในกระบวนการ จึงไม่ไปเพิ่มเวลาในรอบการทำงาน แต่ลดเวลาลง เป็นระบบที่ติดตั้งและบำรุงรักษาง่ายเนื่องจากติดตั้งไว้ภายนอกระบบการตัดเฉือนที่มีสภาพแวดล้อมรุนแรง ทั้งน้ำมันตัด อุณหภูมิสูง การสั่นสะเทือน ฯลฯ

กลุ่มผลิตภัณฑ์เพื่อการผลิตอัจฉริยะ

บริษัท ไทยแมค เซลส์แอนด์เซอร์วิส จำกัด ก่อตั้งขึ้นในปี พ.ศ. 2537 เป็นผู้บุกเบิกการนำเข้าและจัดจำหน่ายเครื่องจักรอุตสาหกรรม และผลิตภัณฑ์และบริการด้านการวัด ซึ่งประกอบด้วยแบรนด์ชั้นนำ อาทิ เครื่องจักร CNC จาก Hurco และ DMG Mori, เครื่องวัดสามมิติ Hexagon CMM, เครื่องเจียร Jagura, เครื่องเจียร Unison และโปรเจ็กเตอร์โปรไฟล์ จาก Baty ในปี 2565 บริษัทได้รีแบรนด์โดยมุ่งมั่นพัฒนาก้าวสู่ยุคอุตสาหกรรม 4.0 ด้วยการเพิ่มโซลูชันระบบอัตโนมัติลงในกลุ่มสินค้าและบริการ โดยเฉพาะชุดผลิตภัณฑ์ซอฟต์แวร์อัตโนมัติจาก Eleven Dynamics ที่ช่วยให้การทำงานร่วมกันของหุ่นยนต์หรือสแกนเนอร์ได้อย่างราบรื่นสำหรับการผลิตอัตโนมัติอัจฉริยะ

ด้วยประสบการณ์จริงหลายสิบปี คุณทวีศักดิ์กล่าวว่าตนยังคงสนุกกับการทำงานและหวังจะนำความรู้และประสบการณ์มาใช้เพื่อประโยชน์ต่ออุตสาหกรรมไทย รวมทั้งสร้างการเติบโตให้บริษัท ไทยแมค เซลส์แอนด์เซอร์วิส จำกัดมากยิ่งขึ้น ซึ่งงาน Thaimach and Hurco Open House 2025 จึงพิสูจน์คำพูดนี้ได้อย่างชัดเจน

Article by: Thaimach Sales & Service Co. Ltd. and MEGATech Thailand << Click Here