ปัจจุบันทุกอุตสาหกรรมกำลังพยายามอย่างเต็มที่ที่จะเดินหน้าสู่การพัฒนาที่ยั่งยืนยิ่งขึ้น ซึ่งรวมถึงภาคส่วนการแปรรูปโลหะแผ่นด้วย แต่การดำเนินงานเพื่อก้าวสู่ความยั่งยืนนั้นอาจเป็นสิ่งที่พูดได้ง่ายกว่าลงมือทำ แล้วจะต้องเริ่มตรงไหนและมีอะไรที่สามารถใช้เป็นแนวทางได้บ้าง คำตอบอยู่ที่กลยุทธ์ด้านความยั่งยืนของ Bystronic

ปัจจุบันมีหลายบริษัทกำลังก้าวเดินบนเส้นทางสู่ความยั่งยืนเพิ่มมากขึ้นเรื่อย ๆ โดยไม่รู้ตัว ตัวอย่างเช่น การประหยัดวัสดุบรรจุภัณฑ์เพื่อลดต้นทุนการขนส่ง ก็เป็นหนึ่งในเส้นทางที่สามารถก้าวสู่ความยั่งยืนได้โดยอัตโนมัติ หรือการที่บริษัทต่างๆ กำลังพยายามลดการใช้วัตถุดิบด้วยการทำให้กระบวนการผลิตมีประสิทธิภาพเพิ่มมากขึ้น ก็ถือเป็นการช่วยรักษาสิ่งแวดล้อมได้ด้วยเช่นกัน รวมถึงการผันความร้อนที่เกิดจากเครื่องจักรไปใช้เป็นระบบทำความร้อนให้กับอาคารสำนักงานก็เป็นตัวอย่างที่ดี

มาตรการดังกล่าวสามารถสร้างผลลัพธ์เชิงบวกได้ถึงสองเท่า เนื่องจากการใช้ทรัพยากรอย่างมีประสิทธิภาพนอกจากจะทำให้ประหยัดค่าใช้จ่ายแล้ว ยังเอื้อประโยชน์ต่อระบบนิเวศของเราด้วย ด้วยเหตุนี้ มาตรการในลักษณะดังกล่าวจึงเป็นหลักการพื้นฐานที่ดีสำหรับกลยุทธ์ด้านความยั่งยืน หากมีการนำเอาความคิดริเริ่มต่างๆ ภายในบริษัทมารวมเข้าด้วยกันและเชื่อมโยงให้สอดคล้องกับวัตถุประสงค์ด้วยแล้ว ก็จะทำให้ได้ภาพที่ชัดเจนยิ่งขึ้นว่า บริษัทกำลังยืนอยู่ ณ จุดใดและยังมีสิ่งใดบ้างที่ต้องรีบดำเนินการแก้ไข

อย่างไรก็ตามมีความจำเป็นเร่งด่วนมากมายที่ต้องรีบดำเนินการในขณะนี้ ไม่ว่าจะเป็นเรื่องน้ำท่วม ภัยแล้ง และความล้มเหลวในการเพาะปลูก ทั้งหมดนี้ล้วนสะท้อนให้เห็นถึงความเป็นจริงอันเนื่องมาจากสภาพภูมิอากาศที่เปลี่ยนแปลงไป ซึ่งรวมถึงความจำเป็นเร่งด่วนในการเปลี่ยนจากเชื้อเพลิงฟอสซิลไปเป็นวัฏจักรพลังงานที่มีความยั่งยืนมากขึ้น โดยสถานการณ์ของราคาพลังงานที่พุ่งสูงขึ้นและการขาดแคลนก๊าซธรรมชาติได้ส่งผลให้ต้องพิจารณาแนวทางใหม่ๆ เพิ่มเติม

เป้าหมายการพัฒนาอย่างยั่งยืนขององค์การสหประชาชาติ (SDG) ได้นำเสนอแนวทางที่น่าสนใจหลายอย่าง

องค์การสหประชาชาติได้กำหนดเป้าหมายการพัฒนาอย่างยั่งยืน (SDG) ไว้ทั้งสิ้น 17 ประการ รวมทั้งได้นำเป้าหมายดังกล่าวมาใช้เป็นแนวทางในการร่างยุทธศาสตร์ความยั่งยืนระดับโลก อันส่งผลให้รัฐสมาชิกทั้งหมดจะต้องรายงานความคืบหน้าเรื่องความยั่งยืนในทุกปี (วาระ 2030)

เป้าหมายเหล่านี้ครอบคลุมถึงประเด็นด้านสิ่งแวดล้อม สังคม และเศรษฐกิจ อีกทั้งยังเป็นหลักการพื้นฐานสำหรับกฎหมายระดับประเทศด้วย แม้ว่าตัวบทกฎหมายที่พร้อมรองรับความสำเร็จในอนาคตอันยั่งยืนจะได้รับการนำไปใช้ในระดับที่แตกต่างกัน แต่การนำไปใช้ดังกล่าวก็ได้ก่อให้เกิดกฎระเบียบที่เข้มงวดเพิ่มมากขึ้นเรื่อย ๆ และแน่นอนว่าสิ่งนี้กำลังสร้างแรงกดดันให้กับอุตสาหกรรมเป็นอย่างยิ่ง โดยบริษัทที่ไม่ดำเนินการสิ่งใดเลยในตอนนี้จะพบว่าอีกไม่นานเกินรอตัวเองจะต้องถูกทิ้งไว้ข้างหลัง

นอกจากนี้ เป้าหมายการพัฒนาอย่างยั่งยืนยังเปิดโอกาสให้บริษัทต่างๆ ในภาคส่วนการแปรรูปโลหะแผ่นสามารถเดินหน้าขับเคลื่อนองค์กรให้ก้าวสู่การความยั่งยืนได้เร็วยิ่งขึ้น โดย Bystronic ได้ร่วมมือกับผู้มีส่วนเกี่ยวข้องจากภายนอกเพื่อพิจารณาว่า SDG ขององค์การสหประชาชาติข้อใดบ้างที่เราสามารถทำได้และต้องเริ่มทำแล้วในวันนี้เพื่อก้าวสู่ความสำเร็จ สิ่งนี้ได้กระตุ้นแรงจูงใจอย่างมหาศาลในหมู่พนักงานของเรา

ความยั่งยืนของลูกค้าสร้างความแตกต่างได้อย่างมาก

เป้าหมายระยะยาวของกลยุทธ์ดังกล่าวคือการบรรลุสู่ “การผลิตที่เป็นกลางต่อสภาพภูมิอากาศ” ซึ่งเกี่ยวข้องกับกรอบแนวทางที่ 1 นั่นคือการปล่อยมลพิษที่องค์กรก่อขึ้นเองโดยตรง และเรามีความคืบหน้าอย่างมากในประเด็นนี้ จะเห็นว่าในปัจจุบันสำนักงานใหญ่ของ Bystronic ในเมืองนีเดอรันซ์ ได้เปลี่ยนมาใช้พลังงานไฟฟ้าที่ได้จากพลังน้ำเต็ม 100 เปอร์เซ็นต์แล้ว รวมทั้งได้ติดตั้งระบบผลิตกระแสไฟฟ้าด้วยเซลล์แสงอาทิตย์และสถานีชาร์จไฟสำหรับยานยนต์ไฟฟ้าด้วย

ขณะที่เรื่องรอยเท้าทางนิเวศ (การวัดผลกระทบจากกิจกรรมของมนุษย์ที่ส่งผลต่อระบบนิเวศ) จะขึ้นอยู่กับกรอบแนวทางที่ 2 ได้แก่ การปล่อยมลพิษที่เกิดขึ้นตลอดทั้งห่วงโซ่อุปทาน โดย Bystronic กำลังร่วมมือกับซัพพลายเออร์ในกระบวนการจัดซื้อจัดจ้างเพื่อช่วยกันวิเคราะห์ว่า เราจะสามารถลดการปล่อยมลพิษสำหรับวัสดุที่สั่งซื้อตลอดทั้งกระบวนการได้อย่างไร นอกจากนี้ยังได้มอบหมายให้หน่วยงานจัดอันดับ EcoVadis เข้ามาประเมินความยั่งยืนของห่วงโซ่อุปทานอย่างสม่ำเสมอด้วย เพื่อจะได้มีแนวทางที่ชัดเจนสำหรับการพัฒนาปรับปรุงให้ดียิ่งขึ้น

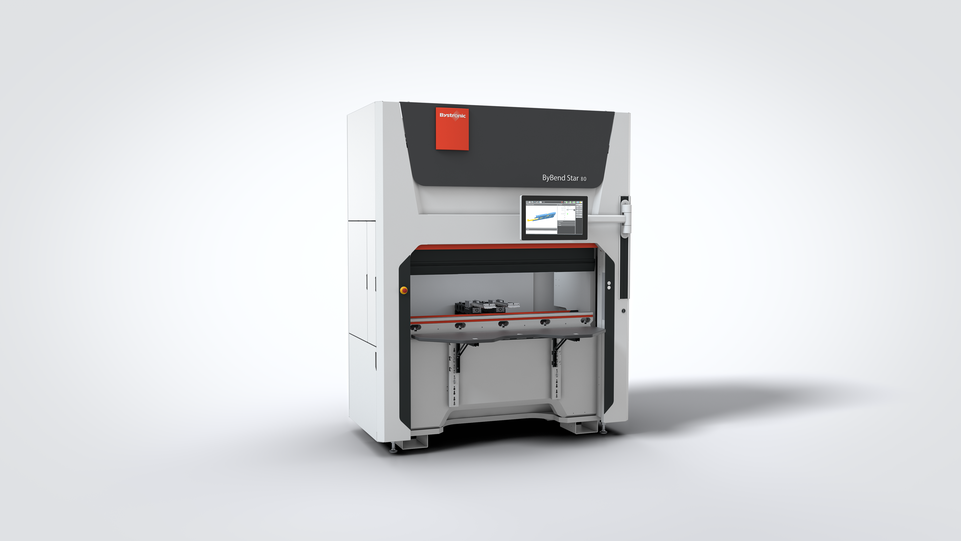

อย่างไรก็ตามในฐานะบริษัทด้านวิศวกรรมเครื่องกลอุตสาหกรรม ผลกระทบที่มีโอกาสเกิดขึ้นได้มากที่สุดของ Bystronic จะอยู่ในกรอบแนวทางที่ 3 นั่นคือ มลพิษที่เกิดจากเครื่องจักรที่เราผลิตขึ้น จึงเป็นเหตุผลว่าทำไม “โซลูชันที่ยั่งยืน” (Sustainable Solution) จึงมีความสำคัญต่อ Bystronic เป็นอย่างยิ่ง การเพิ่มประสิทธิภาพด้านการใช้พลังงานและทรัพยากรของเครื่องจักรที่วางจำหน่าย ทำให้บริษัทสามารถช่วยลูกค้าลดรอยเท้าทางนิเวศได้อย่างชัดเจน นี่คือสิ่งที่เราสามารถดำเนินการได้อย่างเต็มที่

แต่จริงๆ แล้ว เราต้องการทำมากกว่าแค่การปรับปรุงเครื่องจักรของเรา โดย Bystronic ได้ทำงานร่วมกับพันธมิตรด้านพลังงานเพื่อนำเสนอโซลูชันแพ็คเกจที่ดีที่สุดให้กับลูกค้า กล่าวคือ เมื่อมีการซื้อเครื่องจักรไปแล้ว ลูกค้าจะสามารถติดตั้งเครื่องกำเนิดไนโตรเจนและระบบผลิตกระแสไฟฟ้าด้วยเซลล์แสงอาทิตย์ได้พร้อมกัน ทั้งสองสิ่งนี้คือตัวอย่างของการก้าวไปข้างหน้าอย่างงดงามและเกินเกณฑ์มาตรฐานของกฎระเบียบที่มีอยู่ ซึ่งจะเห็นได้ว่าที่ผ่านมานั้น หน่วยงานกำกับดูแลมักจะจัดประเภทเครื่องจักรของเราโดยพิจารณาจากการใช้พลังงานแต่เพียงอย่างเดียว ซึ่งแนวทางดังกล่าวไม่ได้พิจารณาถึงการใช้ไนโตรเจนหรือการใช้พลังงานหมุนเวียนแต่อย่างใด

Article by: Bystronic (Thailand) Co., Ltd. & MEGA Tech