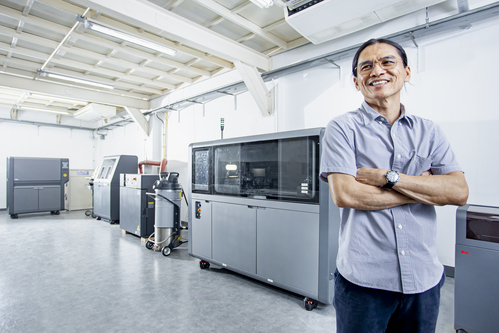

MEGA Tech ได้รับเกียรติสัมภาษณ์ คุณสรพัชย์ อารีอาสนธรรม ประธานกรรมการ บริษัท ซุปเปอร์แมน โฟม อินดัสตรี้ จำกัด ผู้มีประสบการณ์ในวงการอุตสหกรรมการผลิตมานานนับ 18 ปี ได้มีการพลิกโฉมการผลิตในโรงงานโดยใช้ 3D Printer แบรนด์ Desktop Metal เป็นกำลังการผลิตที่สำคัญ โดยผู้ประกอบการสามารถยกระดับจากผู้รับจ้างผลิต (OEMs) มาเป็นเจ้าของแบรนด์สินค้าของตัวเองได้ (OBMs)

คุณสรพัชย์ อารีอาสนธรรม ได้กล่าวถึงจุดเริ่มต้น บริษัท ซุปเปอร์แมน โฟม อินดัสตรี้ จำกัด ว่า “SFI ก่อตั้งเมื่อวันที่ 20 กุมภาพันธ์ 2547 เริ่มจากธุรกิจประเภท Packaging และ Die cutting ซึ่งมีเพียงเครื่อง Die Cutting, Slitting, Rotary, Design & Laser จากนั้นได้เพิ่มกำลังการผลิต เพื่อมาใช้ในการผลิตอย่างเต็มรูปแบบสำหรับธุรกิจกลุ่มยานยนต์ และอิเลคทรอนิกส์ นอกจากนี้ยังเล็งเห็นถึงโอกาสในการเติบโตจากธุรกิจที่เป็นเทคโนโลยีสมัยใหม่คือเครื่อง 3D printer ที่กำลังได้รับความนิยมในปัจจุบันและแน่นอนในอนาคต 3D printing จะเป็นการผลิตรูปแบบใหม่ที่น่าจับตามอง SFI คือบริษัทแรกในเอเซียตะวันออกเฉียงใต้ที่นำเข้าเครื่อง 3D Printer แบรนด์ Desktop Metal รุ่น Shop System เข้ามาใช้ในกระบวนการผลิต นอกจากนี้เรายังมีเครื่อง 3D Printer แบรนด์ HP รุ่น Multi Jet Fusion 4200 โดยจะเป็นการผลิตและบริการภายใต้การบริหารจัดการของบริษัท SAC ซึ่งเป็นบริษัทในเครือของ SFI ทั้งนี้ SAC ได้ก่อตั้งขึ้นเมื่อวันที่ 22 สิงหาคม 2556 เพื่อรองรับเทคโนโลยีและธุรกิจด้านนี้ อย่างไรก็ตาม SAC ได้เปิดตัว 3D printer เมื่อปี 2564 ที่ผ่านมา และกำลังพัฒนาผลิตภัณฑ์เพื่อสร้างแบรนด์ของเราเองได้ในอนาคตข้างหน้า”

ปรับกลยุทธ์ทันสมัย เพื่อความพึงพอใจสูงสุดของลูกค้า

คุณสรพัชย์ได้กล่าวถึงปัจจัยที่ทำให้ประสบความสำเร็จ “SFI & SAC ได้พัฒนาการกระบวนผลิตและรักษามาตรฐานการบริการที่ดีเสมอมาเพื่อให้เกิดความพึงพอใจสูงสุดต่อลูกค้าอย่างต่อเนื่อง ทั้งด้านคุณภาพสินค้าและการจัดส่งที่รวดเร็ว เราได้เพิ่มกำลังการผลิตจาก 1 กะ เป็น 2 กะ เพิ่มเครื่องจักรที่ทันสมัยเพื่อการผลิตที่รวดเร็วและแม่นยำ เพิ่มรถขนส่งเพื่อให้เพียงพอและทันต่อความการต้องการของลูกค้า และขยายพื้นที่โรงงานเพื่อรองรับปริมาณการผลิตที่เพิ่มขึ้น ทั้งนี้การปรับกลยุทธ์และกระบวนการให้ทันสมัยก็สำคัญเพื่อให้เกิดประโยชน์ทั้งสองฝ่าย”

3D Printer แบรนด์ Desktop Metal ตอบโจทย์การดีไซน์อย่างไร้ขีดจำกัด

“SFI & SAC ได้มองเห็นโอกาสในการเติบโตทางธุรกิจ จากเครื่อง 3D printer แบรนด์ Desktop Metal ซึ่งเป็นเทคโนโลยีที่สามารถผลิตชิ้นงานได้หลากหลายรูปแบบและผลิตได้จำนวนมากในคราวเดียวกัน ทั้งยังสามารถลดเวลา ลดคน ในการผลิตได้ด้วย ซึ่งจะสามารถตอบโจทย์สำหรับลูกค้าที่มีดีไซน์หลายแบบที่ไม่สามารถขึ้นรูปทีเดียวพร้อมกันได้ แต่ 3D printer ทำได้ และข้อดีอีกอย่างก็คือการผลิตชิ้นงานโดยไม่จำเป็นต้องสร้างโมลด์ขึ้นมาก่อน ซึ่งช่วยลดค่าใช้จ่ายตรงนี้ได้เป็นอย่างดี ทั้งนี้ 3D printing ยังเป็นเทคโนโลยีที่สามารถนำไปประยุกต์ใช้ได้ในทุกอุตสาหกรรมและสายอาชีพ ด้วยตัวเลือกที่มากขึ้นในตลาด ทำให้ทุกคนสามารถเข้าถึงและใช้ประโยชน์ได้ เช่น ระบบการศึกษา อุตสาหกรรมด้านการแพทย์และทันตกรรม อุตสาหกรรมยานยนต์ อุตสาหกรรมการบินและอวกาศ งานด้านสถาปัตยกรรม งานด้านเฟอร์นิเจอร์ เครื่องประดับและแฟชั่น และในอนาคตอาจรวมไปถึงธุรกิจอาหารที่ผลิตจาก 3D printer ด้วยก็ได้ การมีเครื่อง 3D printer เป็นของเราเองจะทำให้สามารถพัฒนาผลิตภัณฑ์และสร้างแบรนด์เป็นของเราได้ และจะเป็นการสร้างมูลค่าให้กับชิ้นงานนั้นๆได้อย่างยอดเยี่ยม” คุณสรพัชย์ได้กล่าวด้วยน้ำเสียงและสายตาที่มุ่งมั่น

(Right) Panitan Kobkulsuwan, Director of Thaisakol Group Co., Ltd.

Thaisakol จับมือร่วมกันพุ่งทะยานสู่ ยุค Industry 4.0

“THAISAKOL เป็นบริษัทที่มีวิสัยทัศน์เดียวกันกับ SFI & SAC ที่ต้องการก้าวสู่อุตสาหกรรมยุค 4.0 ด้วยความมุ่งมั่นที่จะยกระดับอุตสาหกรรมในประเทศด้วยเทคโนโลยีการผลิตใหม่ๆ ที่ต่างจากปัจจุบันโดยสิ้นเชิง และ 3D printer แบรนด์ Desktop Metal ซึ่งเป็นพันธมิตรกับ THAISAKOL ก็ตอบโจทย์แผนธุรกิจและวิสัยทัศน์นี้ได้เป็นอย่างดี อีกทั้งการบริการหลังการขายที่พร้อมจะให้คำปรึกษาเกี่ยวกับเครื่อง 3D printer ในฐานะตัวแทนนำเข้า ก็มีความสะดวกในการประสานงานและทำงานร่วมกัน เราจึงยินดีที่จะเป็นพันธมิตรด้วยวิสัยทัศน์และการมองเห็นโอกาสเติบโตในอนาคตด้วยเทคโนโลยี 3D printer ไปพร้อมกัน” คุณสรพัชย์กล่าวพร้อมรอยยิ้ม

พลิกโฉมการผลิตรูปแบบ Metal Binder Jetting ด้วย 3D Printing

“3D printing เป็นเทคโนโลยีที่สามารถเปลี่ยนแปลงการผลิตให้เป็นรูปแบบใหม่ เป็นการสร้างความเป็นไปได้ใหม่ๆที่จะเกิดขึ้นในกระบวนการผลิตให้ต่างออกไปจากปัจจุบัน โดยไม่จำเป็นต้องมี tooling ไม่ต้องสร้าง mold ขึ้นมาก่อนที่จะผลิต อีกทั้งยังเป็นการสร้างนวัตกรรมด้านสินค้า การออกแบบ และการผลิตที่ทันสมัย ทำให้เกิดความรวดเร็ว สามารถลดคน ลดเวลา และก้าวสู่ Additive Manufacturing อย่างแท้จริง”

คุณสรพัชย์ได้กล่าวเพิ่มเติมในส่วนนี้ว่า “ส่วนในเรื่องของการเตรียมความพร้อมในการเปลี่ยนแปลงนั้น SFI & SAC มองว่าคืออีกขั้นหนึ่งของการพัฒนากระบวนการผลิตเพื่อให้ทันสมัยมากยิ่งขึ้น ซึ่งคือการปรับตามเทคโนโลยีที่ไม่เคยหยุดนิ่ง และในเมื่อเป็นการเปลี่ยนแปลงที่ดีขึ้น ดังนั้นจึงไม่ได้กังวลอะไรที่จะรีบพัฒนาศักยภาพของเราเอง SFI & SAC จึงได้ฝึกฝนทีมงานให้เรียนรู้และพัฒนาทักษะเกี่ยวกับ 3D printing เพื่อให้เกิดความชำนาญ และเราพร้อมที่จะเป็นผู้นำในธุรกิจ 3D printing และก้าวสู่ยุคอุตสาหกรรม 4.0 อย่างไม่ลังเลใจ”

“3D printing เป็นเทคโนโลยีสมัยใหม่ เป็นนวัตกรรมที่สร้างสินค้าแนวใหม่และสร้างการผลิตที่แตกต่างจากปัจจุบัน เครื่อง 3D printer Desktop Metal รุ่น shop studio ของเรา เป็นเครื่องขนาดใหญ่ สามารถผลิตงาน mass production ได้ วัตถุดิบที่ใช้เป็น Stainless Steel (17- 4PH) เทียบเท่ากับ SUS630 ซึ่งเป็นเกรดเดียวกับที่ใช้ในอุตสาหกรรมกลุ่มเครื่องมือแพทย์ นอกจากนี้เรายังมีเครื่อง 3D printer HP รุ่น Multi Jet Fusion 4200 สำหรับงาน mass production เช่นกัน ซึ่งวัตถุดิบจะเป็นพลาสติก Nylon (PA12) ที่ทำให้ชิ้นงานมีความแข็งแรงทนทาน” คุณสรพัชย์ได้กล่าวทิ้งท้ายเพื่อสร้างความมั่นใจให้กับลูกค้า

Metal Part : Energy Part

Metal Part : Medical Part

Article by: MEGA Tech

Reference:

http://www.supermanfoam.co.th/home-th/

https://www.thaisakolgroup.com/