TEK มากด้วยประสบการณ์ เพียบพร้อมด้วยมาตรฐานการผลิตแม่พิมพ์พลาสติกด้วยเทคโนโลยีที่ดีที่สุด

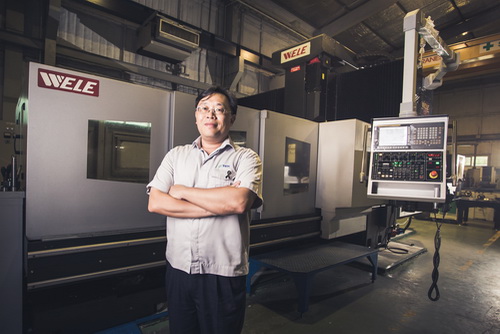

TEK Industries Co.,Ltd. ผู้นำทางด้านการผลิตแม่พิมพ์เพื่องานฉีดขึ้นรูปพลาสติกในอุตสาหกรรมยานยนต์ ไฟฟ้า และอิเล็กทรอนิคส์ บริษัทแห่งนี้เป็นบริศัทถือทุนตางชาาติของไต้หวัน 100% โดยมีบริษัทแม่ในชื่อ TRIO INDUSTRIES Co.,Ltd. ตั้งอยู่ที่ประเทศไต้หวัน นครไทเป ซึ่งได้เข้ามาขยายกิจการในประเทศไทยภายใต้ชื่อ RIO GROUP และก่อตั้งโรงานแม่พิมพ์พลาสติก ในนามบริษัท TEK Industries Co.,Ltd. ที่ ต.แสนภูดาษ อ.บ้านโพธิ์ จ.ฉะเชิงเทรา ในี ค.ศ. 2009 ทั้งนี้ได้รับเกียรติจาก Mr. Feng, Tzung-Hsing, Vice President, TEK Industries Co., Ltd. ได้กล่าวถึงที่มาของการตัดสินใจเข้ามาขายธุรกิจในประเทศไทยว่า “เราเล็งเห็นถึงการเจริญเติบโตของธุรกิจอุตสาหกรรมพลาสติกในเมืองไทยและเขตอาเซียน ไม่ว่าจะเป็นธุรกิจยานยนต์หรืออุปกรณ์เครื่องใช้ไฟฟ้าภายในบ้าน รวมไปถึงอุปกรณ์อิเล็กทรอนิคส์ต่างๆ ซึ่งล้วนเป็นงานที่เรามีความชำนาญและเชี่ยวชาญไม่ว่าจะทักษะในด้านงานฉีดพลาสติก PLASTIC INJECTION หรืองานแม่พิมพ์พลาสติก PLASTIC MOLD ด้วยประสบการณ์ที่สะสมมากว่า 30 ปี เราจึงมั่นใจและตัดสินใจที่จะขยายฐานการผลิต และ support ฐานลูกค้าเดิมที่มีอยู่โดยการสร้างโรงงานเพิ่มอีกแห่งในเมืองไทย” ปัจจุบันทาง TRIO INDUSTRIES CO., LTD. ดำเนินกิจการในประเทศไทยทั้งหมด 3 แห่ง ได้แก่ โรงงานฉีดพลาสติก TTS PLASTIC CO., LTD. ที่ จ.ฉะเชิงเทรา โรงงานฉีดพลาสติก TRIO PLASTIC CO., LTD. ที่ จ.นครราชสีมา และโรงงานผลิตแม่พิมพ์พลาสติก TEK Industries Co., Ltd. ตั้งอยู่ที่ จ.ฉะเชิงเทรา

ปรับปรุงและพัฒนาระบบการผลิต ตอบสนองควมต้องการลูกค้า

ด้วยการเติบโตทางด้านอุตสาหกรรมในประเทศไทยรวมถึงในภูมิภาคอาเซียนที่สูงขึ้นอย่างต่อเนื่อง จึงเป็นปัจจัยสำคัญที่ทำให้ทางบริษัทเร่งขยายและพัฒนาโรงงานให้มีเทคโนโลยีการผลิตที่ทันต่อความต้องการในอนาคต Mr. Feng, Tzung-Hsing กล่าวว่า “เราเล็งเห็นว่าอุตสาหกรรมเกี่ยวกับแม่พิมพ์และงานฉีดพลาสติก ยังมีการเจริญเติบโตอย่างต่อเนื่องในประเทศไทย อีกทั้งการลงทุนของกลุ่มนักลงทุนต่างชาติหรือกลุ่มนักลงทุนไทยเองก็ดี ไม่ว่าจะเป็นในส่วนงานเทคโนโลยี หรือ งานยานยนต์ และภาครัฐเองก็ยังมีการออกนโยบายการส่งเสริมการส่งออก และผลักดันให้ไทยกลายเป็นศูนย์กลางการกระจายสินค้า เพื่อดึงดูดนักลงทุนต่างชาติให้เข้ามาลงทุนในประเทศไทยเพิ่มขึ้นเรื่อยๆ ซึ่งในแต่ละผลิตภัณฑ์ หรือชิ้นส่วนของผลิตภัณฑ์ใดๆ ก็ตามล้วนต้องมีชิ้นส่วนพลาสติกเข้ามาเป็นส่วนประกอบทั้งสิ้น อาจกล่าวได้ว่าทุกที่ ทุกผลิตภัณฑ์ที่เกี่ยวข้องกับการใช้ชีวิตประจำวัน ตั้งแต่ลืมตาตื่นจนเปลือกตาค่อยๆปิดลงจากความอ่อนล้าในการใช้ชีวิตประจำวันของแต่ละคน แต่ละทุกเพศวัย ล้วนต้องมีงานพลาสติกเข้ามาเกี่ยวข้องในทุกๆจังหวะการใช้ชีวิตทั้งสิ้น ดังนั้นด้วยจุดๆ นี้ทางเราจึงพยายามพัฒนาและปรับปรุงเทคนิคด้านการผลิต เพื่อที่จะตอบสนองความต้องการของกลุ่มลูกค้าทุกประเภท และวางแผนในการให้บริการแบบ one stop service เพียงคุณก้าวเข้ามาหาเราทุกความต้องการ หรือปัญหาเกี่ยวข้องกับงานพลาสติก จะมีเราเป็นคนค่อยช่วยและนำพาคุณไปสู่จุดหมายปลายทางที่คุณตั้งไว้ ปัจจุบันเรามีความเชี่ยวชาญด้านการผลิตแม่พิมพ์หลากหลายประเภท โดยงานแม่พิมพ์ที่สร้างชื่อเสียง คือ การผลิตแม่พิมพ์ระบบ Heat & Cool หรือ Steam injection ซึ่งเป็นการออกแบบพิเศษแตกต่างจากแม่พิมพ์ธรรมดาทั่วไป และสามารถตอบสนองความต้องการของลูกค้าในกลุ่มงานเงา หรืองาน High Gloss ซึ่งกลุ่มลูกค้าหลัก ณ ปัจจุบัน ได้แก่ เครื่องใช้ไฟฟ้าภายในบ้านที่เป็นแบรนด์ญี่ปุ่นชั้นนำ และกลุ่มงานยานยนต์ เกือบทุกค่าย”

ด้วยคุณภาพเครื่องจักร Wele และการบริการหลังการขายที่ดีเยี่ยม

ดังที่กล่าวในข้างต้นกว่า TEK มุ่งเน้นในการพัฒนาสายการผลิตอย่างต่อเนื่องมาโดยตลอด จึงเป็นเหตุผลสำคัญในการลงทุนเครื่องจักรใหม่เพื่อเพิ่มประสิทธิภาพให้กับสายการผลิต “จุดสำคัญของการลงทุนของเราในแต่ละครั้ง คือการเข้าไปมีส่วนช่วยตอบสนองความต้องการของลูกค้าให้บรรลุจุดประสงค์ตามเป้าหมายให้ได้มากที่สุด เพราะฉะนั้น เครื่องจักรที่เราคาดหวัง จึงต้องมีความแม่นยำ ถูกต้อง เพื่อจะเป็นอีกทางหนึ่งในการเพิ่มศักยภาพในการผลิต ช่วยประหยัดเวลา และลดต้นทุน ซึ่งถือเป็นหัวใจสำคัญมากๆ ต่อกระบวนการผลิตในอุตสาหกรรมประเภทนี้ ดังนั้นเราจึงมีนโยบายที่จะสั่งซื้อเครื่องจักรขนาดใหญ่เพิ่มเติมเพื่อที่จะนำมาเพิ่มศักยภาพในการผลิต ซึ่ง Wele ก็เป็นแบรนด์ของเครื่องจักรหนึ่งที่เราตัดสินใจเลือกใช้ นอกจากนี้ยังเกิดจากการเข้าไปเยี่ยมชมการจัดแสดงสินค้าและออกบูธที่งานจัดแสดงสินค้าแห่งหนึ่งในประเทศไทยจึงได้มีโอกาสทำความรู้จักกับทาง Oni Intertrade Co., Ltd. ซึ่งเป็นผู้แทนจำหน่ายอย่างเป็นทางการในประเทศไทย เมื่อสอบถามและพิจารณาก็เห็นว่า มีคุณสมบัติที่แตกต่างจากแบรนด์อื่นๆ ประกอบกับมีศูนย์ service ภายในประเทศไทย ซึ่งเป็นจุดสำคัญและช่วยในการตัดสินใจได้ง่ายขึ้นในการเลือกพิจารณาสั่งซื้อเครื่องของ Wele”

ด้วยวิสัยทัศน์และความจริงใจในการผลิตสินค้าให้ได้มาตรฐานตามที่ลูกค้าต้องการมากที่สุดคือสิ่งสำคัญที่ทำให้กลุ่มบริษัท TRIO GROUP ประสบความสำเร็จและเติบโตอย่างต่อเนื่องทั้งนี้ Mr. Feng, Tzung-Hsing กล่าวทิ้งท้ายว่า “ทีมงานของเราถูกสั่งสมประสบการณ์จากรุ่นสู่รุ่น ถ่ายทอดจากประสบการณ์การเรียนรู้โดยตรงกว่า 30 ปี จึงอาจพูดได้ว่าเรามีความชำนาญและทักษะทุกรูปแบบทั้งทางด้านการออกแบบ ตลอดจนการผลิตแม่พิมพ์พลาสติกให้ออกมาตรงตามที่ลูกค้าต้องการ เพื่อส่งมอบผลิตภัณฑ์ที่มีคุณภาพและได้มาตรฐานคืนให้แก่ลูกค้าที่ไว้วางใจ TEK”