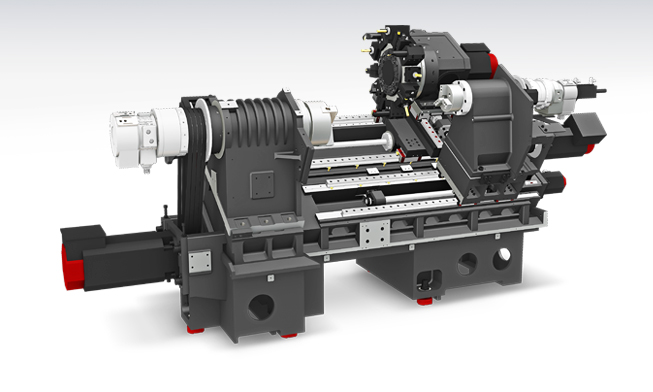

แท่นเครื่องแบบอเนกประสงค์ ALL-IN-ONE

วิเคราะห์โครงสร้างเพื่อประสิทธิภาพที่ดีที่สุด

การวิเคราะห์โครงสร้างเป็นส่วนหนึ่งของแนวทางการออกแบบเครื่องจักรของเรา เพื่อเพิ่มความแข็งแกร่งของสะพานมีด และลดขนาดความสูงของเครื่องจักร เพื่อให้แท่นเครื่องมีความมั่นคงตลอดเวลาแม้จะเป็นการตัดเฉือนความเร็วสูง นอกจากนั้นแล้ว แท่นเครื่องของรุ่น SE Series ยังมีระดับความลาด 30 องศา เพื่อให้มั่นใจได้ถึงการตัดเฉือนที่มั่นคงยิ่งขึ้น

รางนำ

รางนำลิเนียร์มอเตอร์ความเร็วสูง

รางนำลูกล้อของลิเนียร์มอเตอร์ทำหน้าที่ลดระยะเวลาสูญเปล่าที่เครื่องจักรไม่ได้ทำการตัด พร้อมทั้งเพิ่มความแข็งแกร่งให้กับเครื่อง

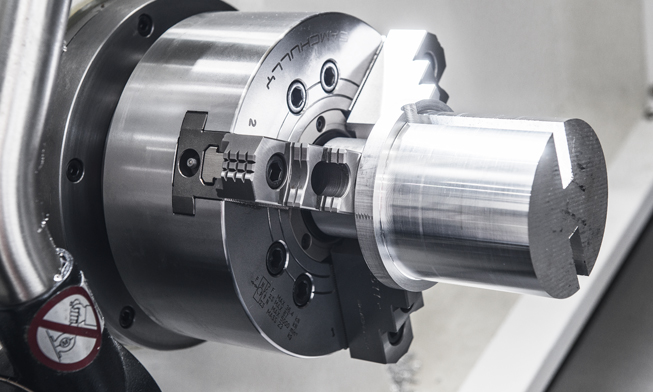

สปินเดิลหลัก

ออกแบบพิเศษสำหรับงานตัดหยาบและงานตัดเฉือนความเร็วสูง

สปินเดิลหลักขนาด 6 นิ้ว ออกแบบสำหรับการตัดเฉือนความเร็วสูงโดยเฉพาะ โดยมีการใช้แบริ่งลูกปืนสองแถวที่ด้านหน้าและสามแถวที่ด้านหลัง นอกจากนั้นแล้ว สปินเดิลหลักขนาด 8 และ 10 นิ้วยังมีการออกแบบโครงสร้างให้มีความแข็งแรงสูง โดยใช้แบริ่งลูกกลิ้งสองแถวและคอนแทคต์แบริ่ง ซึ่งให้ประสิทธิภาพดีเยี่ยมสำหรับงานตัดเฉือนหนัก

นอกจากนี้ เรายังใช้สายพาน Ribstar เพื่อลดการลื่นและเสียงของสายพานในระหว่างการทำงาน ซึ่งช่วยเพิ่มประสิทธิภาพและความเชื่อถือได้ให้กับการทำงาน เนื่องจากสามารถป้องกันความเสียหายของแบริ่งจากน้ำมันซึมเข้า

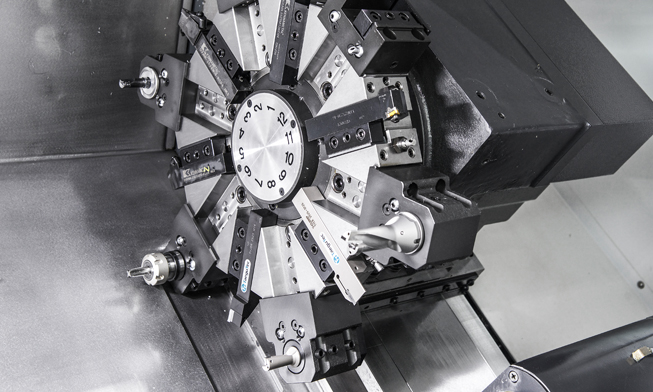

ระบบควบคุมแกน C (‘M’ Type): แกน C ของรุ่น SE Series สามารถควบคุมได้ละเอียด 0.001° ทำให้สามารถตัดเฉือนชิ้นงานได้หลากหลายรูปทรง

สปินเดิลรอง (‘S’ Type)

สปินเดิลรองแบบทรงระฆัง ผ่านการออกแบบเพื่อป้องกันการขยายตัวเนื่องจากความร้อนในระหว่างการตัดเฉือนต่อเนื่องติดต่อกันสำหรับงานตัดเฉือนหนักและงานตัดเฉือนความเร็วสูง โดยหลังจากที่สปินเดิลหลักทำการตัดเฉือนเสร็จแล้ว การหมุนของสปินเดิลรองจะซิงค์กับสปินเดิลหลัก เพื่อให้สามารถย้ายชิ้นงานไปยังสปินเดิลรองได้ และสามารถเริ่มการตัดเฉือนที่ด้านหลังของชิ้นงานได้

Article by : Cerathai