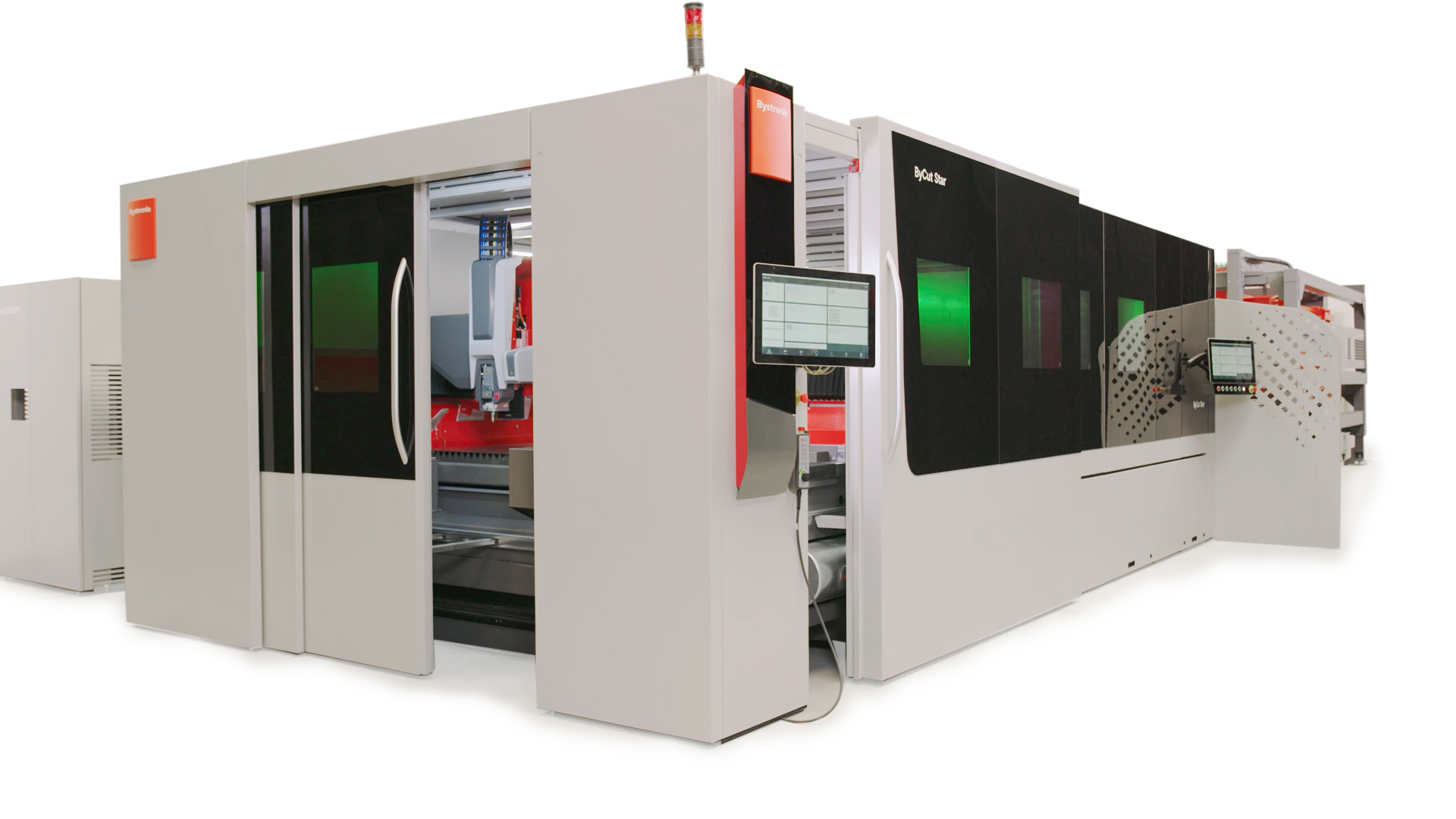

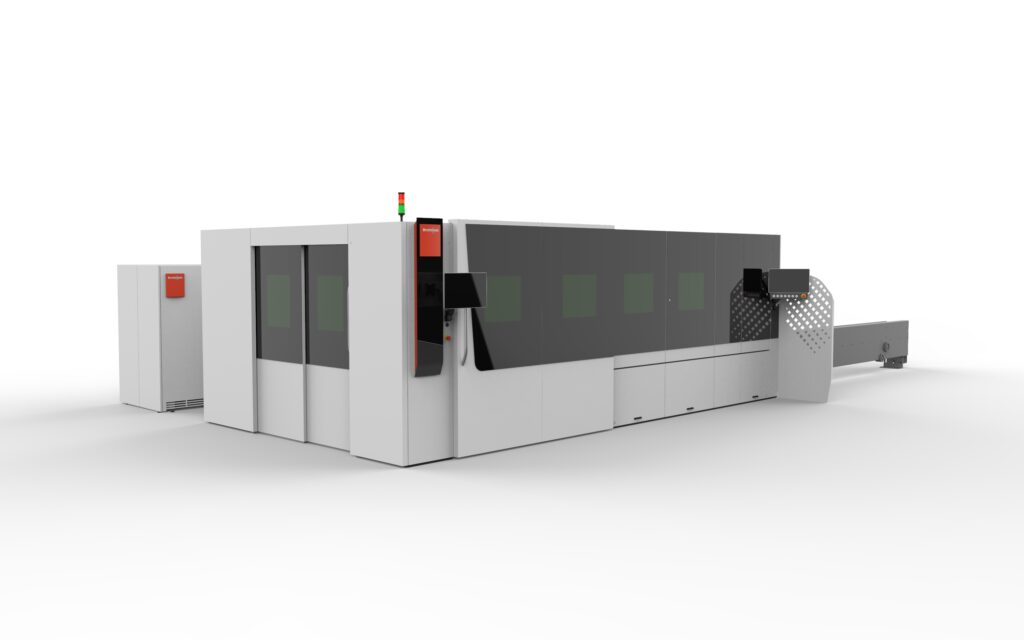

เครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเหล็ก ( laser cutting ) ที่มีความเร็วสูงเป็นพิเศษ ระบบการตัดอัจฉริยะ และการออกแบบใหม่ทุกจุด ทั้งหมดนี้คือคุณสมบัติของเครื่องตัดเลเซอร์ เครื่องตัดเหล็ก ( laser cutting ) ByCut Star รุ่นใหม่ที่มาพร้อมกับกำลัง 30 กิโลวัตต์และระบบตัดเหล็กอัจฉริยะที่ให้ประสิทธิภาพสูงสุด ตัดวัสดุได้อย่างเที่ยงตรงและเชื่อถือได้ ไม่ว่าจะเป็นเหล็กกล้า อะลูมิเนียม สเตนเลสสตีล ทองเหลือง และทองแดง ให้คุณภาพงานตัดเหนือกว่าอีกระดับ

เครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเหล็ก ( laser cutting ) รุ่นหลักจาก Bystronic กำลังสูง 30 กิโลวัตต์ ช่วยให้บริษัทในธุรกิจแปรรูปโลหะแผ่นสามารถเพิ่มประสิทธิภาพการผลิตได้อีกขั้น ด้วยไฟเบอร์เลเซอร์แบบใหม่ที่มาพร้อมระบบตัดเหล็กอัจฉริยะ

นอกจาก เครื่องตัดไฟเบอร์เลเซอร์ ( laser cutting ) ที่มีเลเซอร์กำลังสูงที่ช่วยให้งานตัดมีทั้งคุณภาพและประสิทธิภาพสูงขึ้นแล้ว ระบบตัดเหล็กอัจฉริยะก็เป็นอีกส่วนหนึ่งที่เข้ามาเสริมในจุดนี้ด้วยเช่นกัน โดย Bystronic กำลังก้าวสู่มิติใหม่ของการตัดเหล็กด้วยเครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting ) เพื่อให้ลูกค้าในธุรกิจแปรรูปโลหะแผ่นสามารถแข่งขันได้อย่างมีประสิทธิภาพมากยิ่งขึ้น ด้วยเครื่องตัดไฟเบอร์เลเซอร์ ByCut Star ใช้ระบบตัดเลเซอร์กำลังสูงพิเศษ 30 กิโลวัตต์ และเป็นระบบไฟเบอร์เลเซอร์ไฮเทคที่ให้ความเที่ยงตรงสูงตามแบบฉบับของ Bystronic คงความเชื่อถือได้ของกระบวนการตัดเหล็กแม้จะใช้กำลังเลเซอร์ระดับสูงสุด พร้อมทั้งรองรับงานได้หลากหลายรูปแบบ เพื่อให้ลูกค้าในธุรกิจแปรรูปโลหะแผ่นสามารถยกระดับประสิทธิภาพและความรวดเร็วได้อีกขั้น

เครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting ) ของเราก้าวนำหน้าคู่แข่งอยู่เสมอ

ความสำเร็จของธุรกิจแปรรูปโลหะแผ่นนอกจากจะต้องการเลเซอร์กำลังสูงในการตัดเหล็กแล้ว ยังจำเป็นต้องมีระบบการทำงานที่อัจฉริยะ เชื่อถือได้ และยั่งยืน แน่นอนว่าประสิทธิภาพถือเป็นหัวใจสำคัญ แต่ระบบการทำงานและคุณสมบัติอัจฉริยะก็เป็นอีกส่วนประกอบหนึ่งที่จะทำให้การตัดด้วยเครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting ) มีประสิทธิภาพเป็นที่น่าพอใจและประสบความสำเร็จ

Bystronic เชื่อว่าความสำเร็จของลูกค้าขึ้นอยู่กับเสาหลักสามเสา ได้แก่ กำลัง ระบบตัดอัจฉริยะ และการปรับปรุงกระบวนการตัด เช่น โดยการใช้เทคโนโลยี MixGas

คุณสมบัติอัจฉริยะ เช่น “ระบบการตัดอัจฉริยะ” (Intelligent Cutting Process หรือ ICP) ระบบ KerfScan สำหรับควบคุมหัวยิงเลเซอร์” (Nozzle Control Tool หรือ NCT) หรือ “ระบบช่วยเลือกการตั้งค่า” (Parameter Wizard) คือสิ่งที่จะช่วยเพิ่มประสิทธิภาพให้กับงานตัด พร้อมทั้งควบคุมกระบวนการตัดเหล็กให้เหมาะสม เพื่อให้แน่ใจว่า ลูกค้าสามารถที่จะใช้งานเครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting )ได้อย่างเต็มประสิทธิภาพและต่อเนื่อง โดยไม่ต้องคอยกังวลกับปัญหาเวลาสูญเปล่า

เครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting ) สร้างความแตกต่างด้วยระบบการทำงานอัจฉริยะ

ระบบการทำงานอัจฉริยะของเครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting )เครื่องตัดเลเซอร์ Bystronic รุ่นใหม่ช่วยให้ผู้ผลิตและแปรรูปโลหะแผ่นทำงานได้ด้วยคุณภาพระดับสูงสุด

ระบบ NCT และ KerfScan เป็นแพ็คเกจอัจฉริยะสำหรับระบบเลเซอร์ออกซิเจน โดยจะช่วยเพิ่มความเชื่อถือได้ของกระบวนการตัด แม้จะเป็นระบบการผลิตแบบใช้คนควบคุมบางส่วน ระบบนี้มาพร้อมคุณสมบัติการตรวจสอบกระบวนการ การแก้ปัญหา และการดำเนินกระบวนการตัดต่อเนื่องแบบอัตโนมัติเต็มรูปแบบ

“Parameter Wizard” ในเครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting )เครื่องตัดเลเซอร์ ช่วยให้มั่นใจได้ว่า ชิ้นงานจะมีคุณภาพสูงสุดทุกครั้ง โดยระบบจะช่วยเลือกค่าการตัดที่ดีที่สุดภายในเวลาเพียงไม่กี่นาที ช่วยเพิ่มความสะดวกให้แก่ผู้ควบคุมที่อาจจะยังไม่เคยมีประสบการณ์หรือมีประสบการณ์น้อย โดยระบบจะใช้เวลาเพียงไม่กี่นาทีในการคำนวณค่าที่ดีที่สุดสำหรับ N2 และ MixGas ที่เหมาะกับการตัดเหล็กกล้าแผ่นที่มีความหนาตั้งแต่ 4 ถึง 15 มม.

ระบบการตัดอัจฉริยะ (Intelligent Cutting Process หรือ ICP) เป็นคุณสมบัติใหม่ ซึ่งใช้กล้องแบบแกนร่วมเพื่อจับภาพผ่านหัวยิงเลเซอร์ ทำให้สามารถเห็นกระบวนการตัดได้

เครื่องตัดเลเซอร์รุ่นหลักของ Bystronic ยังสามารถควบคุมการทำงานได้ผ่านทางหน้าจอสัมผัสขนาด 21.5 นิ้ว ใช้งานง่ายไม่ต่างจากโทรศัพท์มือถือ

นอกจากนี้ เครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting )เครื่องตัดเลเซอร์ ByCut Star ยังมาพร้อมกับดีไซน์ที่สวยงาม ด้วยรูปทรงทันสมัยและเส้นสายที่คม ให้รูปลักษณ์สวยงามที่มาพร้อมกับประสิทธิภาพการตัดที่เหนือกว่า พร้อมด้วยการออกแบบที่เน้นความสะดวกในการใช้งานและความยืดหยุ่นมากยิ่งขึ้น ไม่ว่าจะเป็นจุดเข้าถึงตัวเครื่องที่ด้านหน้าและ/หรือด้านข้าง รวมไปถึงช่องกระจกมองหลายจุดเพื่อให้สามารถตรวจสอบกระบวนการตัดได้อย่างสะดวก ตัวเครื่องยังมีการออกแบบให้เข้าถึงภายในเครื่องได้สะดวกมากขึ้น และสามารถติดตั้งภายในพื้นที่โรงงานได้สะดวกและยืดหยุ่นมากยิ่งขึ้น

เครื่องตัดไฟเบอร์เลเซอร์ เครื่องตัดเลเซอร์ ( laser cutting )เครื่องตัดเลเซอร์ มีระบบไฟเบอร์เลเซอร์แบบก๊าซผสม – คุณภาพและประสิทธิภาพการตัดที่เหนือกว่า

สำหรับกระบวนการตัดเลเซอร์ ก๊าซตัด (โดยเฉพาะ N2 และ MixGas) จะทำหน้าที่ป้องกันเลเซอร์และโลหะแผ่นจากสิ่งปนเปื้อน รวมไปถึงขจัดวัสดุหลอมเหลวออกจากชิ้นงาน ก๊าซไนโตรเจนจะใช้สำหรับการตัดแบบฟิวชั่น ในขณะที่ก๊าซออกซิเจนจะใช้สำหรับการตัดด้วยเปลวไฟ การผสมก๊าซทั้งสองชนิดนี้เข้าด้วยกันจะทำให้ได้ข้อดีของทั้งก๊าซ O2 และ N2 และเป็นอีกทางเลือกหนึ่งสำหรับใช้แทนก๊าซไนโตรเจนหรือออกซิเจนบริสุทธิ์ การตัดด้วย MixGas (ก๊าซผสมระหว่างไนโตรเจน/ออกซิเจนในอัตราส่วนเฉพาะ) จะช่วยให้การตัดเหล็กกล้ามีคุณภาพสูงสุดและตัดเหล็กได้เร็วขึ้น แม้จะเป็นเหล็กกล้าคุณภาพต่ำก็ตาม

Bystronic มีเครื่องกำเนิดก๊าซ N2 สำหรับผลิตก๊าซในสถานที่ ซึ่งทั้งคุ้มค่าต่อราคาและเป็นมิตรต่อสิ่งแวดล้อม โดยมีข้อดีที่เห็นได้อย่างชัดเจน เช่น ไม่จำเป็นต้องขนส่งก๊าซด้วยรถบรรทุก สามารถผลิตก๊าซไนโตรเจนได้เท่าที่ต้องการ และตัดต้นทุนเพิ่มเติมในเรื่องอื่นๆ ทั้งหมด ไม่ว่าจะเป็นขั้นตอนการเติมก๊าซลงถังไปจนถึงการเปลี่ยนถังก๊าซใหม่ ผู้ผลิตและแปรรูปโลหะแผ่นจึงสามารถดำเนินธุรกิจได้ด้วยตนเองโดยไม่ต้องพึ่งพาซัพพลายเออร์ก๊าซจากภายนอก พร้อมทั้งยังช่วยลดผลกระทบต่อสิ่งแวดล้อมได้อีกทางหนึ่ง

Article by: Bystronic (Thailand) Co., Ltd. << Click Here