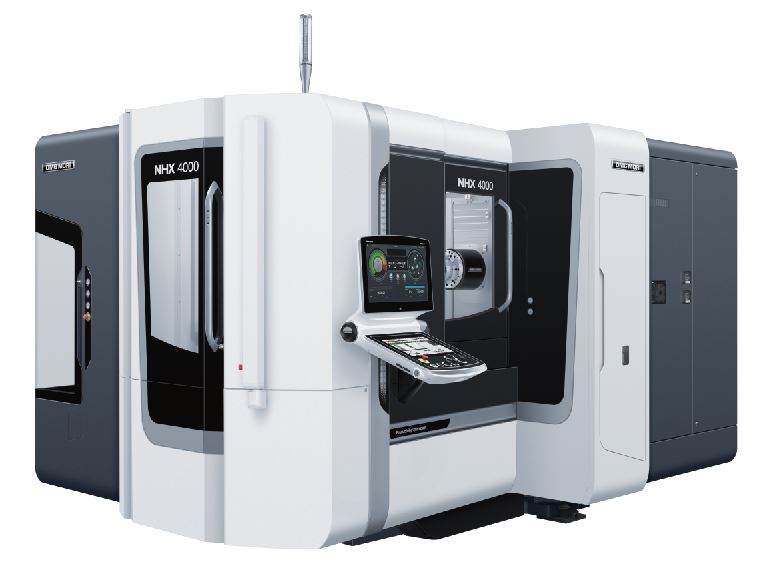

เครื่องแมชชีนนิ่งเซ็นเตอร์แนวนอน NHX 4000 รุ่นที่ 3 เหมาะเป็นพิเศษสำหรับการผลิตชิ้นงานจำนวนมากในอุตสาหกรรมยานยนต์และอากาศยาน ซึ่งต้องการความแข็งแรงและความแม่นยำสูง เครื่องแมชชีนนิ่งเซ็นเตอร์รุ่นนี้มาพร้อมอุปกรณ์มาตรฐานอย่างสปินเดิลความเร็วสูง speedMASTER และแท่นชิ้นงานที่หนาและแข็งแรงเป็นพิเศษ ทำให้มั่นใจได้ถึงการตัดเฉือนที่รวดเร็วและความแม่นยำสูงทุกครั้ง รวมทั้งยังมีถังน้ำหล่อเย็น Zero Sludge ที่สามารถกักเก็บเศษเมือกภายในถังได้อย่างมีประสิทธิภาพ ทำให้สามารถดูแลรักษาถังน้ำหล่อเย็นได้ง่ายยิ่งขึ้น

นอกจากนี้ ยังมีระบบควบคุมแบบลูปปิดสำหรับทุกแกน เพื่อให้การตัดเฉือนมีความแม่นยำสูง อินเตอร์เฟสควบคุมความดันไฮดรอลิกและนิวเมติกเป็นอุปกรณ์มาตรฐานที่ติดตั้งมากับเครื่อง ซึ่งช่วยให้สามารถทำงานแบบอัตโนมัติได้ ส่งผลให้ประสิทธิภาพการผลิตสูงขึ้นอย่างมาก DMG MORI มีโซลูชั่นระบบอัตโนมัติและระบบหุ่นยนต์รูปแบบต่างๆ ให้เลือกมากมายตามลักษณะการผลิตของโรงงานของคุณ