Moving to smaller batches emphasizes the need for quicker set-up changes. Moving to minimum stock-levels of parts is now more realistic than ever before through re-setting to varying jobs of similar part families. To maximize real production time when batches of parts can be manufactured from large to medium the green-light machining part of production time becomes more important to tackle with the smallest possible machine stoppages. Quick change tooling is a key factor.

Machine tools are to an increasing extent designed with flexibility to improve changeovers between part types. There are numerous examples where both CNC turning-centres and multi-task machines have facilities that increase the machining possibilities in one basic set-up with reduced changeover times within families of parts. Options are many and there is therefore a lot to consider when manufacturing re-invest in production equipment. A step towards leaner manufacturing, with lower stock levels of parts becomes more attractive.

To start with, every manufacturer in the auto component area can benefit from taking a new look at the combined effects of machine utilization and actual cutting efficiency. This is how the opportunities for improved productivity and payback become apparent. Machine shops often want to understand where they stand today and have ambitions where they want to go – but how? Investing in the right machine and the most suitable equipment makes a bigger difference today.

If a shop already has machinery, why did they buy that type, not include certain options, those possibilities and the list goes on. Boundaries do exist but in this situation it pays to look beyond obvious limitations. There are significant upgrading possibilities in machines and equipment.

If re-investing in new machinery, on the other hand, this should be seen as a golden opportunity to step up into another league as regards capability, results and profitability. Analysing the objectives, requirements, investment and options can lead to answers that make a real difference to productivity. Tooling has a lot more to offer than just a cutting edge.

But what if a machine shop has a proven concept that works and has been running that for many years successfully – why not stick to that and replicate it? Machine shops that take the line of using their traditional outlook on machines, equipment, processes, tools, programmes and methods and do not take the step-changing opportunities that new technology after all presents, will inevitably be left behind. There is no need for turning centres to have the green light on for only 65% of the production time. Nor is there any need to over-invest in machinery or be limited in machining possibilities.

Early collaboration with the partners that provide machinery, equipment, tooling and software is the only direction that will deliver the right, modern machining solution, adding competitiveness to shops. The right-from-the-start philosophy for the total solution ensuring no boundaries provides the greatest value for the customer. A good internal and external stakeholder analysis needs to be the basis to define an adequate specification of demands. There are two machinery areas that tend to be under-analysed. These are the more traditional machines: turning centres and machining centres, where there are today many modern options available, which really increase productivity. Yet they often overlooked.

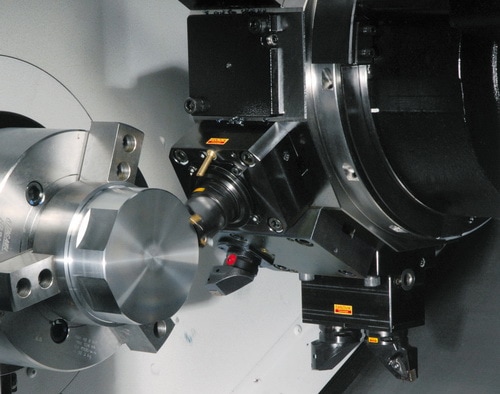

Driven tools in turning centres are very powerful today and, along with a y-axis, cover most 3-axis milling/drilling requirements. Shops should also think carefully before excluding the y-axis option as it also adds extra turning positions – which further reduces set-up. Quick change or automatic tool change is very important to consider because set-up time on a lathe is a big time-consumer. Tools should be pre-set outside the machine whilst it is running and stoppages for tool-change minimized whatever the tooling system, although a modular tooling system has clear benefits.

When it comes to machining centres, comparing the machine utilization of one with a pallet and one without, is staggering. The extra investment is always worth it – and here also consider an extra-large tool magazine, which covers all the parts in a family or can accommodate sister tools for continuous running.

Finally, high-pressure coolant facilities in turning and rotating tool machines have to be mentioned today. Through-tool coolant at 70 bar pressure is increasingly proving itself as part of a set-up in steel machining that adds productivity and process security as so much has happened with tools that have precision jets assisting machining