The recent arrival of PrimeTurning™ from Sandvik Coromant, an all-directional turning and tools has re-written the conventional rules of this age-old machining process, offering tantalising improvements in productivity. The question for machine shops now is whether they can – or should – make use of this new process in their own operations.

There are many challenges facing modern machine shops looking to achieve competitive gain and increase order levels. Not least among them is productivity. Factors such as inefficient cycle times and bottlenecks have the potential to slow order throughput and damage business reputation through delayed deliveries. Many assume that turning, as a mature machining process, has reached its limit in terms of technological step-changes, leaving machine shops feeling frustrated with slow speeds and feeds.

And yet there is a solution: all-directional turning allows manufacturers to achieve more without any investment in costly capital equipment such as new machine tools. In fact, this radically different approach permits customers to harness the power and capabilities of machines already owned.

One insert, three functions

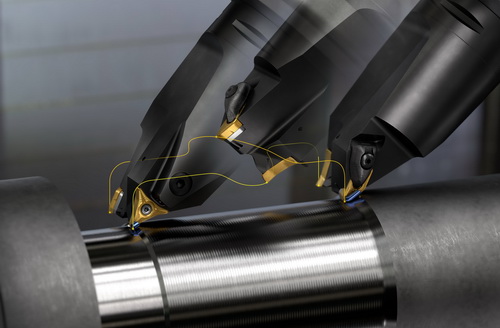

As part of PrimeTurning™ functionality, the process also provides for all-directional turning, which means that conventional turning (from part-end to chuck) can be performed using the same tools. In fact, the inserts have three edges/corners, one for longitudinal turning, one for facing and one for profiling, thus delivering efficient edge utlisation and longer tool life.

CoroTurn® Prime A-types feature three 35° corners and are designed for light roughing, finishing and profiling, while

CoroTurn Prime B-types with their ultra-strong corners are designed specifically for rough machining. The tools are purpose-designed for use with precision coolant. CoroTurn Prime A-types come with under- and over-coolant provision, while CoroTurn Prime B-types offer just under-coolant. As a rule, under-coolant should always be applied for better tool life, with over-coolant is used for chip control.

The only machine required is a CNC turning centre. To highlight the potential gains on offer, when turning a hub made from cast steel (SAE/AISI 1045) on a Gildemeister CTV 250 turning centre, a machining company in Brazil was able to achieve significant benefits. Using the same cutting speed (300 m/min, 984 ft/min) as a competitor insert, the adoption of the latest all-directional inserts allowed feed rates to be increased from 0.25 mm/r (0.01 inch/r) to 0.4 mm/r (0.016 inch/r), and depth of cut from 1.5 mm (0.059 inch) to 3 mm (0.118 inch). The result was a 59% increase in productivity and 55% more tool life. With over 120,000 hubs a year being produced, the impact on profitability is considerable.

85% increase in productivity

A further example can be seen at a machine shop in Italy producing parts from forged nickel alloy (ASTM B564) on a Doosan Puma 3100M turning centre. Here, the application of the latest inserts permitted cutting speed to be increased from 150 m/min (492 ft/min) to 300 m/min (984 ft/min), feed rates to be elevated from 0.3 mm/r (0.012 inch/r) to 0.8 mm/r (0.032 inch/r), and depth of cut to be doubled from 2 mm (0.079 inch) to 4 mm (0.156 inch). The outcome has seen an 85% increase in productivity and 125% more tool life. Annual volumes for this particular part are in the region of 5000.

The inserts are supported by a large number of tool holder variants, including Coromant Capto®, QS™ shank and conventional shank. Complementing the tooling is the PrimeTurning code generator, which supplies programming codes that are compatible with a wide variety of CNC machines. The new code generator not only ensures maximum output, but also process security with suitably adjusted feed rate and entry radius parameters.